Buoyancy mounting method for blocks

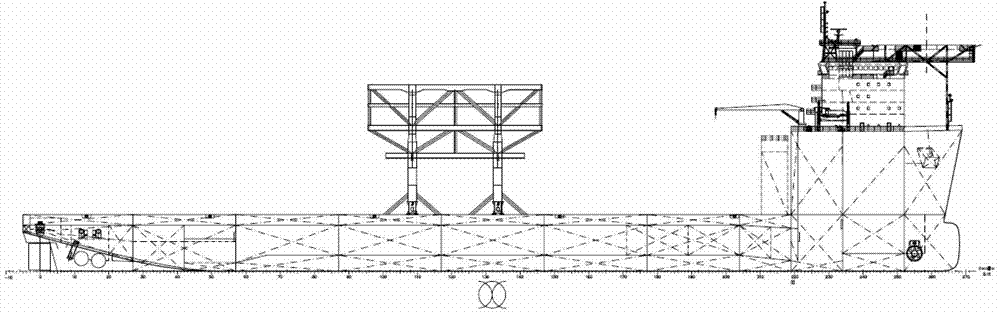

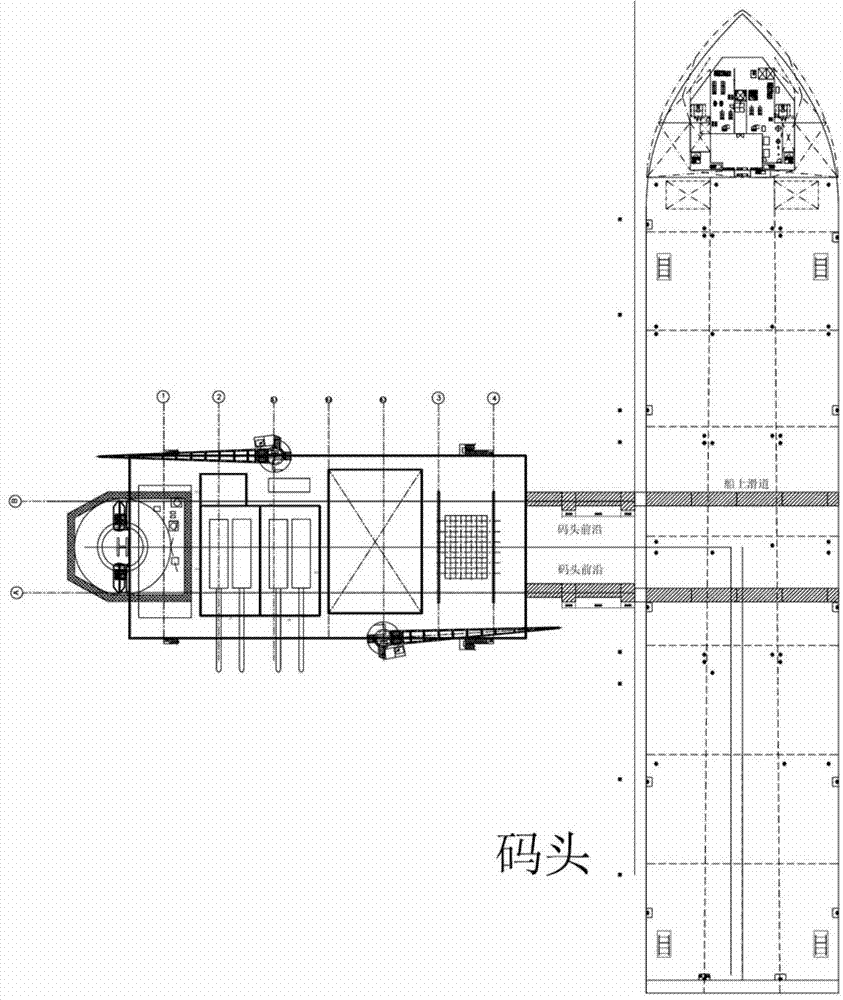

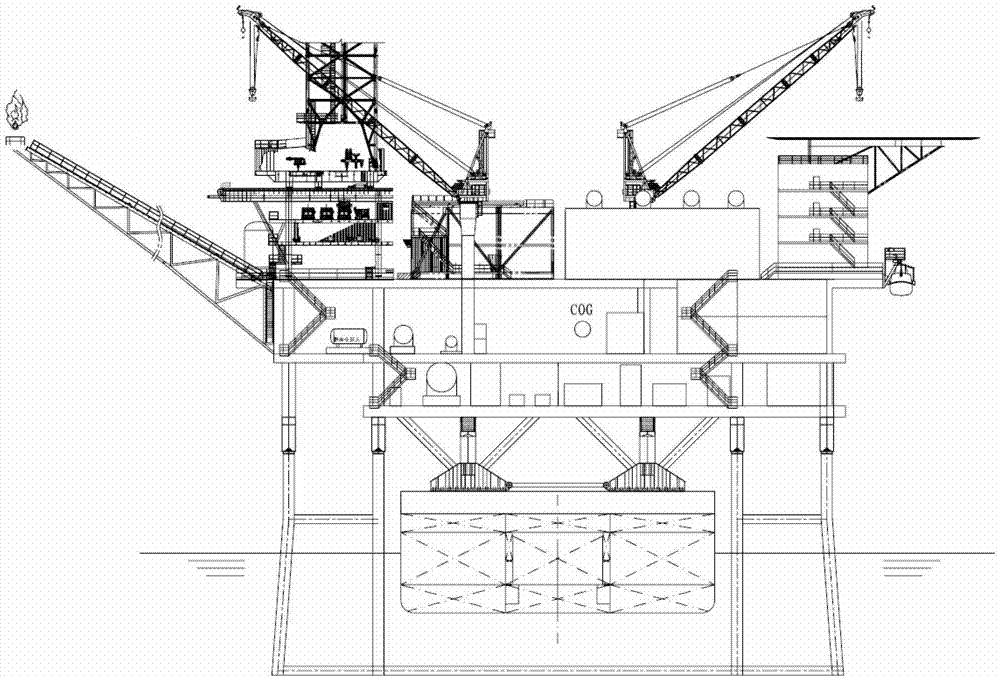

An installation method and block technology, which are applied in transportation and packaging, ship parts, ships, etc., can solve the problems of not being able to ensure that the project is put into production on schedule, affecting the project duration, etc., so as to shorten the offshore operation time, reduce installation and tugboat transportation, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0028] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

[0029] In the early stage of construction, it is necessary to design the appropriate number of slideways on the dynamic positioning ship according to the weight center of gravity of the block and the conditions of the slideway at the construction site, generally 2 to 4; the number of slideways on the wharf and the main deck of the dynamic positioning ship The number of slides on the track can be different or equal. Sliding shoes or DSF (Deck Support Frame) shall be built on the slipway on the pier, and DSU shall be installed on the slipping shoe or DSF, wherein, the slipping shoe is matched with the slipway on the dynamic positioning ship; 4~8 LMUs (set block docking device) mounted on the pillars of the block.

[0030] Such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com