Automatic counting device for bearing parts

An automatic and counting machine technology, applied in conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of low efficiency, bloated personnel, low efficiency, etc., to improve work efficiency, reduce the probability of rework, and reduce labor. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

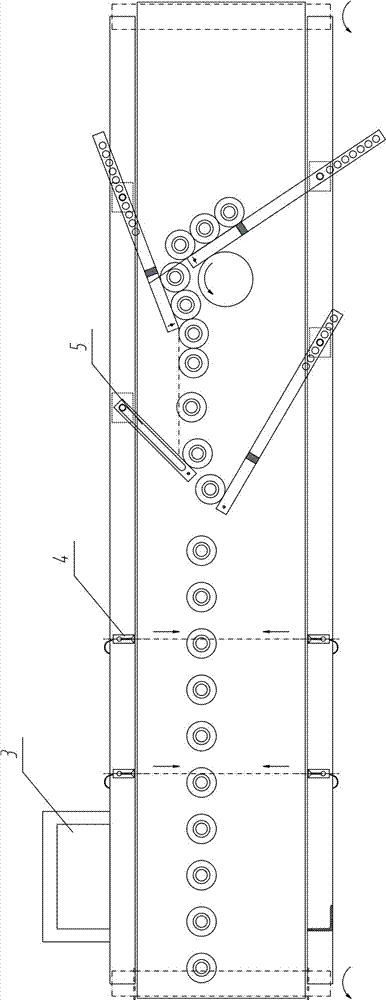

[0015] The belt-type automatic counting machine includes two sets of inclined block type spacers arranged above the conveyor belt. The product is isolated, and two groups of photoelectric signal detectors, PLC controllers, frequency converters and touch screens are arranged behind it. The photoelectric signal detectors include infrared detectors symmetrically arranged on both sides of the belt. The photoelectric signal detectors The controller is connected with the PLC controller, and connected with the touch screen through the communication cable, the PLC controller is connected with the frequency converter through the intermediate relay, the frequency converter is connected with the three-phase motor, and the three-phase motor controls the speed of the conveyor belt.

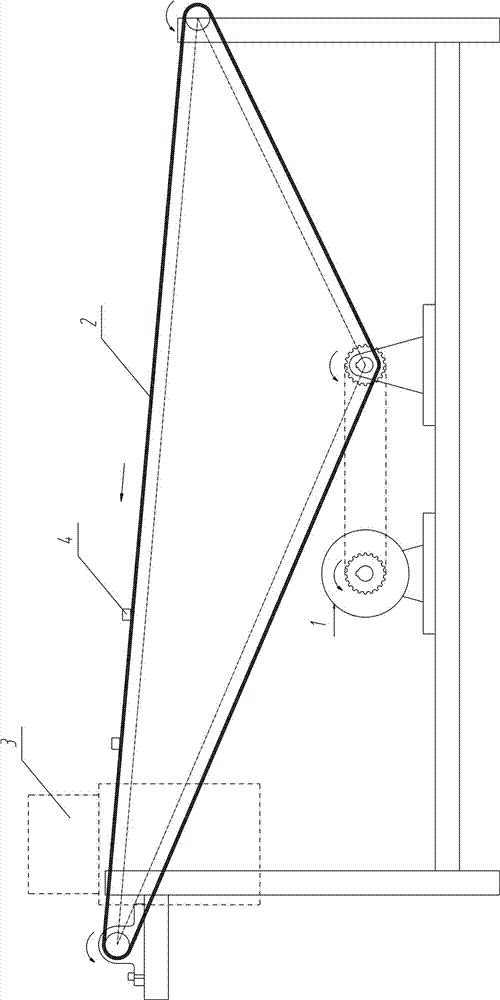

[0016] Such as Figure 1-2 As shown, the present invention utilizes the three-phase moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com