A kind of preparation technology of camouflage tent cloth

A preparation process and tent cloth technology are applied in the field of preparation technology of camouflage tent cloth, which can solve the problems of destroying dyes, destroying the fabric itself, decreasing strength and the like, and achieving the effects of low economic cost, reasonable process and high water repellency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

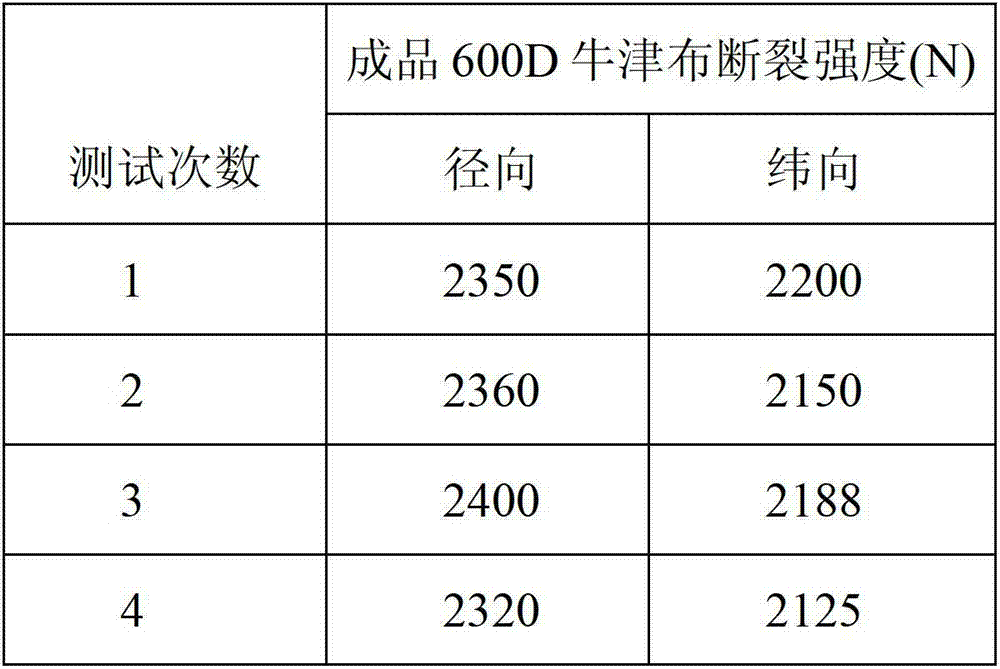

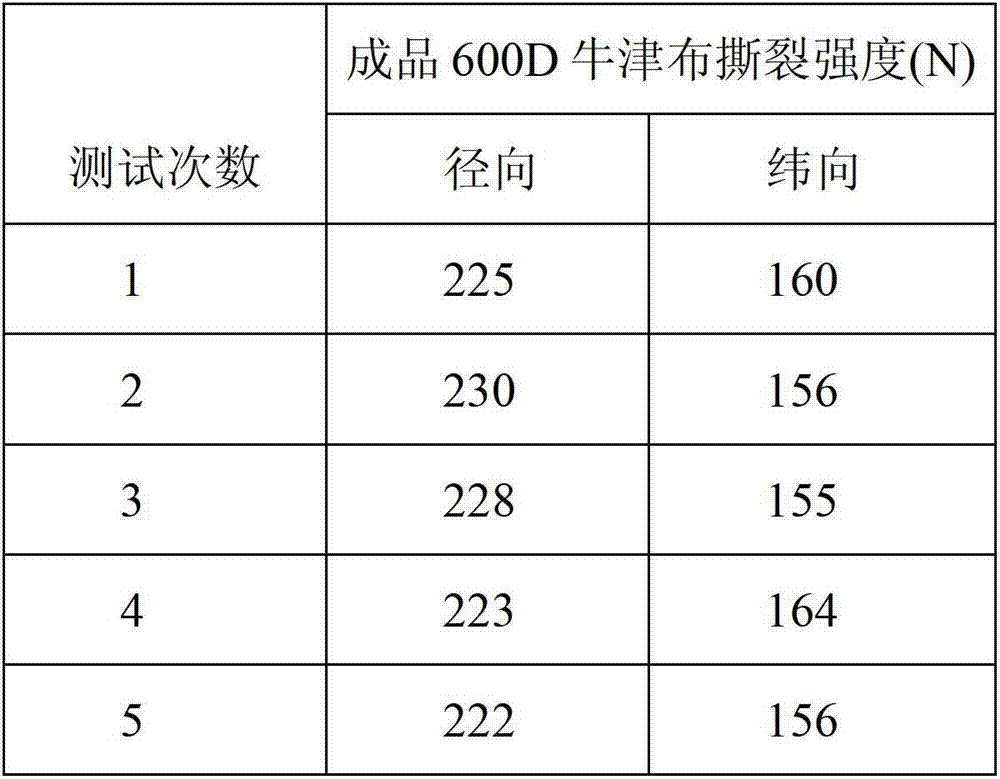

Embodiment 1

[0046] A preparation process of a camouflage tent cloth, comprising the following steps: the first step, pre-treating the base cloth for dyeing, printing, coating, and setting; the second step, using disperse dyes for dyeing with near-infrared shielding function The base fabric is dyed with the dye solution of the ultraviolet absorber; the third step is to select the printing paste including the disperse dye for printing with near-infrared shielding function to print the dyed base fabric; the fourth step is to use polyamide resin glue Make a primer on the base fabric after printing; the fifth step is to apply PVC whitening to the base fabric after the primer with PVC coating paste; the sixth step is to apply PU to the base fabric after the PVC whitening with polyurethane silver paste Silver surface coating; step 7, padding the base fabric after PU silver surface coating in water-repellent finishing solution, drying and baking. The amount of disperse dye used for dyeing in the ...

Embodiment 2

[0048] The difference from Example 1 is that the amount of disperse dye used for dyeing in the dyeing liquor is 0.5% (owf), and the amount of ultraviolet absorber is 0.5% (owf). The amount of dispersant in each liter of dyeing liquor is 1g, the amount of high-temperature leveling agent in each liter of dyeing liquor is 1g, and the amount of penetration in each liter of dyeing liquor is 2g. In the second step, when dyeing, first put the dye solution and the base cloth at room temperature, adjust the pH of the dye solution to 4.5, then raise the temperature to 50°C in 15 minutes, and then raise the temperature to 125°C in 50 minutes, and then After 80 minutes of heat preservation, cool down and restore the base fabric to be cleaned, and the dyeing solution is a liquor ratio of 1:30. The weight ratio of the disperse dye for printing, the synthetic thickener and the binder is 0.5:60:4. The weight ratio of the polyamide resin coating glue, crosslinking agent and solvent is 100:1:8...

Embodiment 3

[0050]The difference from Example 1 is that the amount of disperse dye used for dyeing in the dyeing liquor is 2.5% (owf), and the amount of ultraviolet absorber is 2.5% (owf). The amount of dispersant in each liter of dyeing liquor is 2g, the amount of high-temperature leveling agent in each liter of dyeing liquor is 2g, and the amount of penetration in each liter of dyeing liquor is 0.5g. In the second step, the dye solution has a bath ratio of 1:50. The weight ratio of the disperse dye for printing, the synthetic thickener and the binder is 2.5:90:15. The weight ratio of the polyamide resin coating glue, the crosslinking agent and the solvent is 90:1.5:4. When preparing the polyamide resin glue, adjust the viscosity to 10000mPa·S. The process parameters when using polyamide resin glue in the fourth step are as follows: select a sharp-angle scraper, adjust the scraper angle to 115 degrees, adjust the magnetic force of the magnetic roller to 90%, control the temperature in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com