Internal double-layer prefabricated traffic lane structure of shield tunnel

A shield tunnel and driveway technology, applied in the structural field of prefabricated components, can solve the problems of dense personnel, many construction procedures, long construction period, etc., and achieve the effect of accelerating construction speed, rapid construction, and reducing construction personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

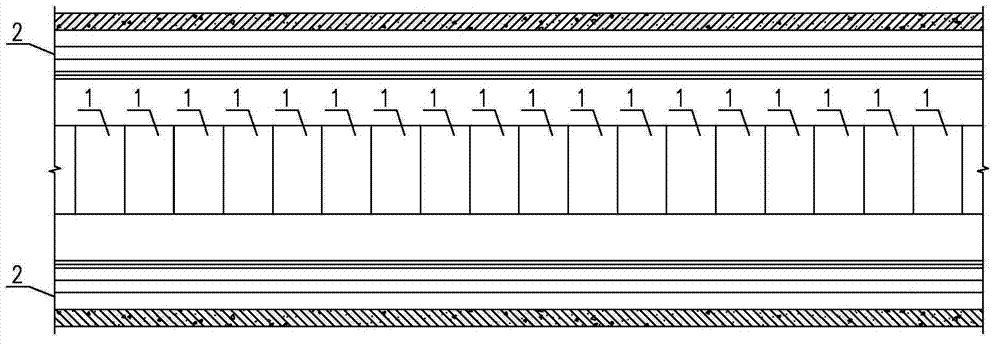

[0030] 1) see figure 1 , to pave the lower driveway with a glyph-shaped prefabricated component 1;

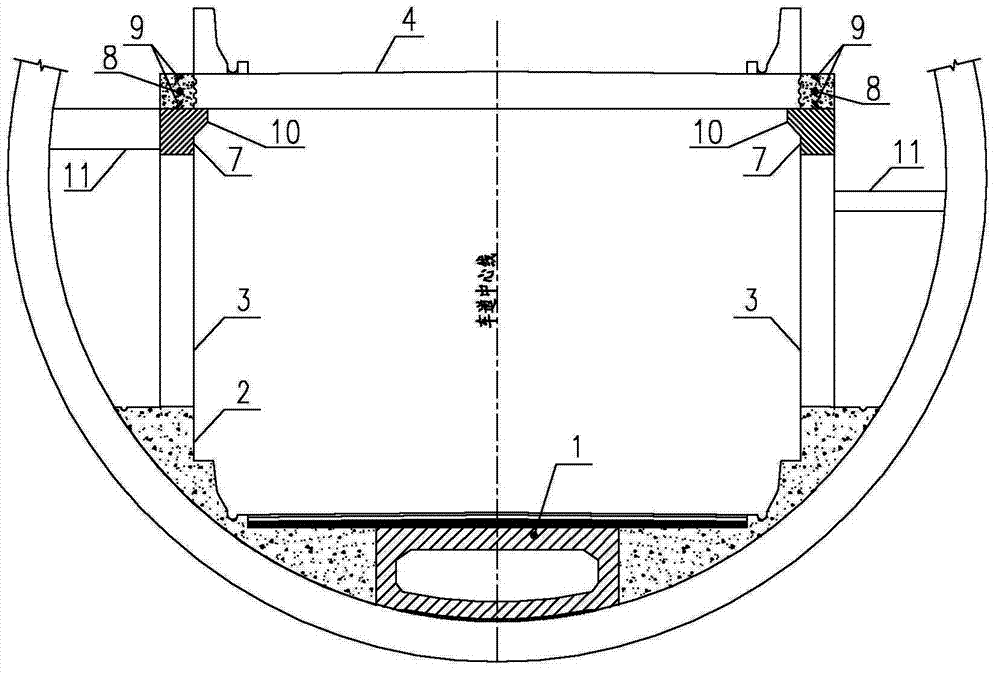

[0031] 2) see figure 2 Concrete the driveway foundation 2, the upper driveway column 3, the driveway column connecting beam 11, and the upper driveway stringer 7 on both sides of the zigzag prefabricated components that have been paved in the lower driveway, and set the driveway stringer corbel 10 on the inner side of the upper driveway stringer 7 (Such as Figure 4 shown);

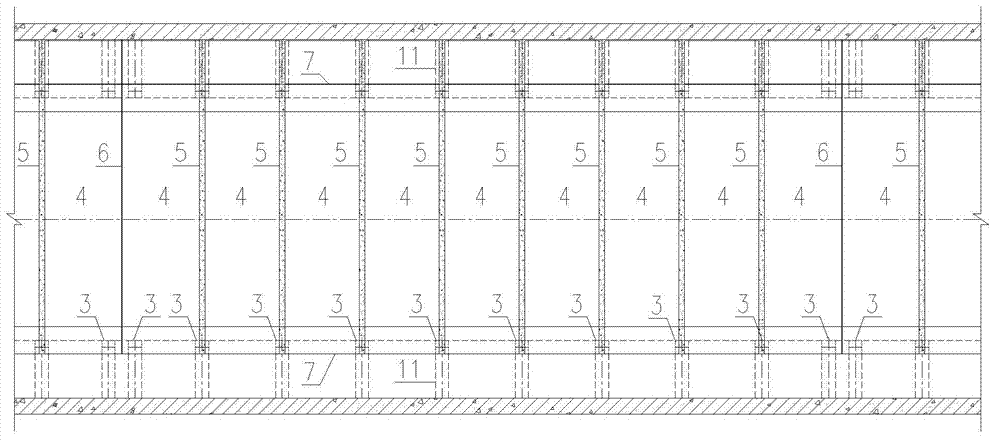

[0032] 3) see figure 2 and image 3 , hoisting the prefabricated slab 4 of the upper lane on the foundation 2 of the upper lane. When hoisting the prefabricated slabs 4 of the upper driveway, a hinge joint 5 for construction is left between every two precast slabs 4 of the upper driveway. The lane prefabricated slab 4 and the upper lane longitudinal beam 7 are poured with concrete at 8 post-pouring joints, so that an integral structure is formed between the upper lane prefabricated slab 4 and betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com