Cable-stayed bridge saddle and manufacturing method thereof

A technology for cable-stayed bridge cables and a manufacturing method, which is applied to bridges, bridge parts, bridge construction and other directions, can solve the problems of anti-skid reliability limitation of side steel cables, inconvenient use of cable saddles, etc., so as to achieve convenient use and replacement, and save bridge construction. cost, the effect of avoiding slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

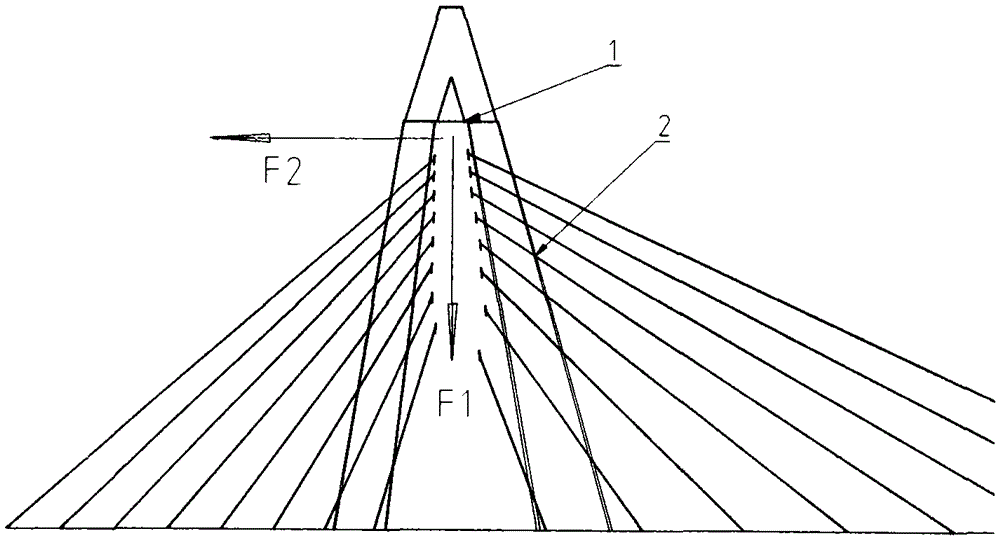

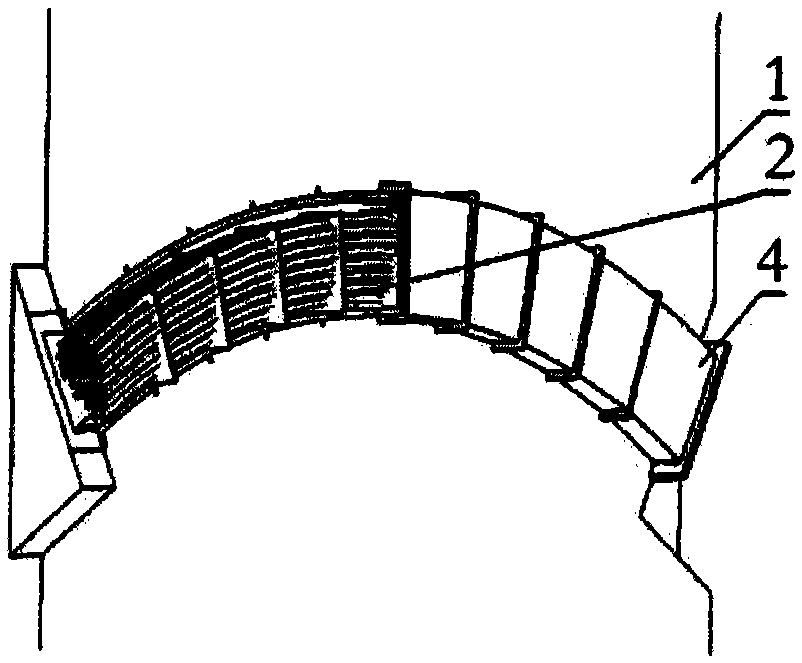

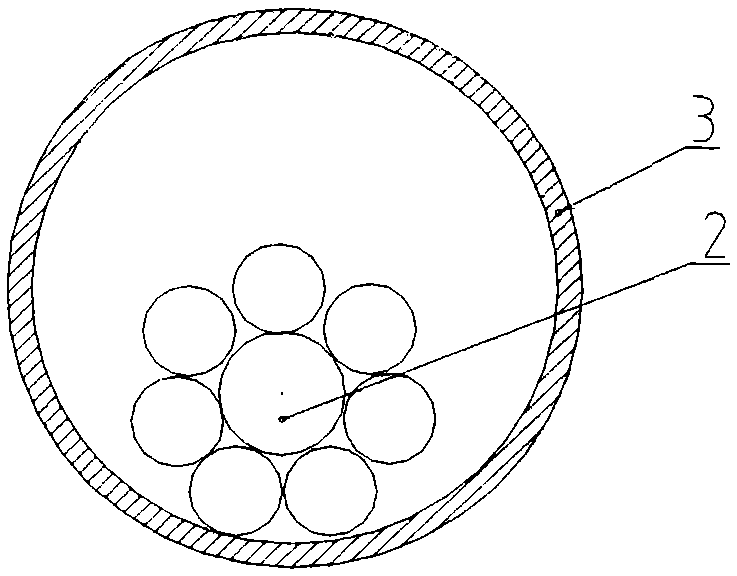

[0030] see Figure 5 , Figure 6 , a new type of cable-stayed bridge cable saddle 4' provided by the present invention is provided with several water-drop-shaped wire-dividing pipes 3', and the water-drop-shaped wire-dividing pipes 3' are pierced with a plurality of steel cables 2. The steel cable group 2', the outer surfaces on both sides of the steel cable group 2' are arranged against the inner walls on both sides of the bottom of the drop-shaped wire splitting tube 3'.

[0031] By using the two tapped surfaces at the bottom of the drop-shaped wire splitting tube 3', the steel cable 2 can be locked in the two tapped surfaces so that it cannot slip. The angle formed by the two tapped surfaces is preferably 60°. The locking of the steel cable 2 can be effectively ensured.

[0032] As a transformation of the present embodiment, the water drop type wire splitting tube 3' can also be replaced by any other wire splitting tube that can fix the steel cable group 2' at its bottom....

Embodiment 2

[0034] see Figure 7 , during manufacture, earlier saddle body 5 is made moulding, penetrates water-drop shape splitting pipe 3 ', then the inner chamber of saddle body 5 is filled with C50 self-compacting concrete 6 and then builds into cable tower body. The steel cable 2 passes through the drop-shaped wire splitting pipe 3' on the main tower and presses on the cable tower body. The cable saddle with this structure relieves the horizontal component force of the steel cable 2 on the bridge tower. There is only one vertical downward force on the tower. It eliminates the damage of the horizontal component force to it, and also reduces the engineering cost. This structure changes the radius of the cable tower saddle according to the height of different types of bridges, which can solve the requirements of the cable tower at any height.

Embodiment 3

[0036] The proportioning of C50 self-compacting concrete 6 in embodiment 2 is as follows:

[0037] cement 480kg / m 3

gravel 1019kg / m 3 sand 680kg / m 3

fly ash 58kg / m 3 water 200kg / m 3

expansion agent 70kg / m 3

[0038] For example, when preparing 33L of C50 self-compacting concrete 6 test blocks, the proportion can be:

[0039] cement 15.84kg / m 3

gravel 33.627kg / m 3 sand 22.44kg / m 3

fly ash 1.914kg / m 3 water 6.6kg / m 3

expansion agent 2.31kg / m 3

[0040] When preparing 40L of C50 self-compacting concrete 6 test blocks, the proportion can be:

[0041] cement 19.2kg / m 3

gravel 40.76kg / m 3 sand 27.2kg / m 3

fly ash 2.32kg / m 3 water 8.00kg / m 3

expansion agent 2.8kg / m 3

[0042] When preparing 50L of C50 self-compacting concrete 6 test blocks, the proportion can be:

[0043] cement 24.00kg / m 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com