Method for constructing concrete pile through rotary excavating and pressure irrigation

A construction method and technology for pouring concrete, which are applied in the fields of earthwork drilling, sheet pile wall, foundation structure engineering, etc., can solve the problems of increasing engineering cost, difficult control, and long slag cleaning time, so as to ensure the settlement quality and improve the construction. The effect of speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A construction method for rotary excavation and grouting concrete piles is characterized in that it comprises the following steps:

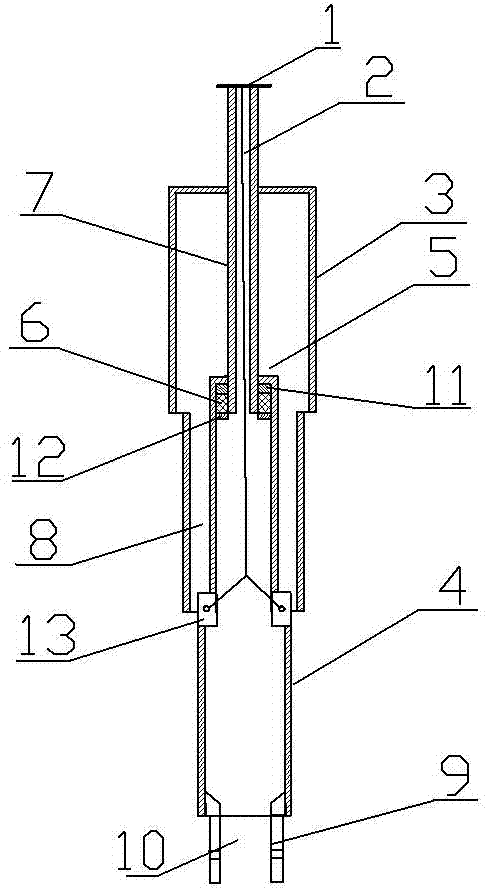

[0021] Step 1: Use a rotary drilling rig for construction, drill to the predetermined depth of the pile hole, then lift the rotary drilling bucket, replace it with a multi-functional slag cleaning tube and put it into the bottom of the pile hole for slag cleaning construction;

[0022] Step 2: After cleaning the sediment at the bottom of the pile hole, reverse half a circle to open the concrete output valve at the bottom of the multi-functional slag cleaning cylinder, while slowly lifting the rotary drilling rod, while passing through the rotary drilling rod and the rotary drilling machine Concrete conveying pipe with synchronous self-expanding activities pours concrete into the pile hole;

[0023] Step 3: hoist the reinforcement cage, insert the reinforcement cage into the pile by using the weight of the reinforcement cage and the vibrato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com