Foundation pile with high bearing capacity and its treatment method with foundation

A bearing capacity and foundation pile technology, which is applied in the field of high bearing capacity foundation piles and their treatment with foundations, can solve problems such as extrusion damage of front root piles, poor soil bearing capacity, insufficient frictional resistance, etc., and achieve increased bearing capacity Force and friction, improved seismic performance, quick and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

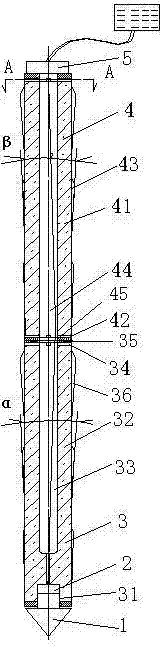

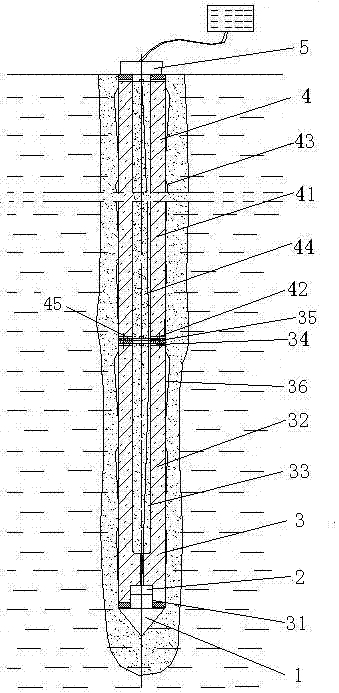

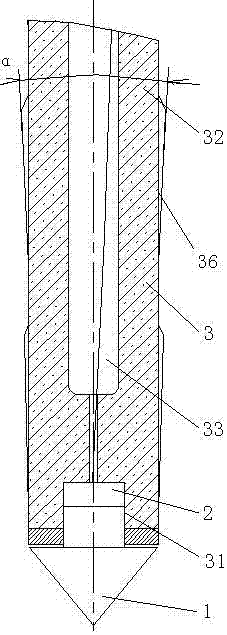

[0024] Refer to attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 , attached Figure 6 , the high bearing capacity foundation pile of the present invention, it is made up of pile head 1, lower end pressure detector 2, bottom pile body 3, upper pile body 4, upper end pressure detector 5, is provided with pile at the end of bottom pile body 3 The head 1 is provided with a lower end pressure detector 2 in contact with the pile head 1 in the inner cavity of the lower end of the bottom pile body 3. The lower end pressure detector 2 is a pressure detection device, and is detected outside the foundation through a data line. connected to the instrument. The upper pile body 4 is connected with the bottom pile body 3 through a connection plate, and the bottom pile body 3 is a tubular pile body with a multi-stage tapered surface; the bottom pile body 3 is composed of a detector device end 31, Bottom pile body 32, bottom pile center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com