Inside engaged gear pump with static pressure supporting device

An internal gear pump, hydrostatic support technology, applied in the direction of rotary piston type/swing piston type pump components, pumps, pump components, etc., can solve the problems of reduced mechanical efficiency of gear pumps, limited pressure specifications, and shortened life. , to achieve the effect of improving mechanical efficiency, increasing output pressure and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

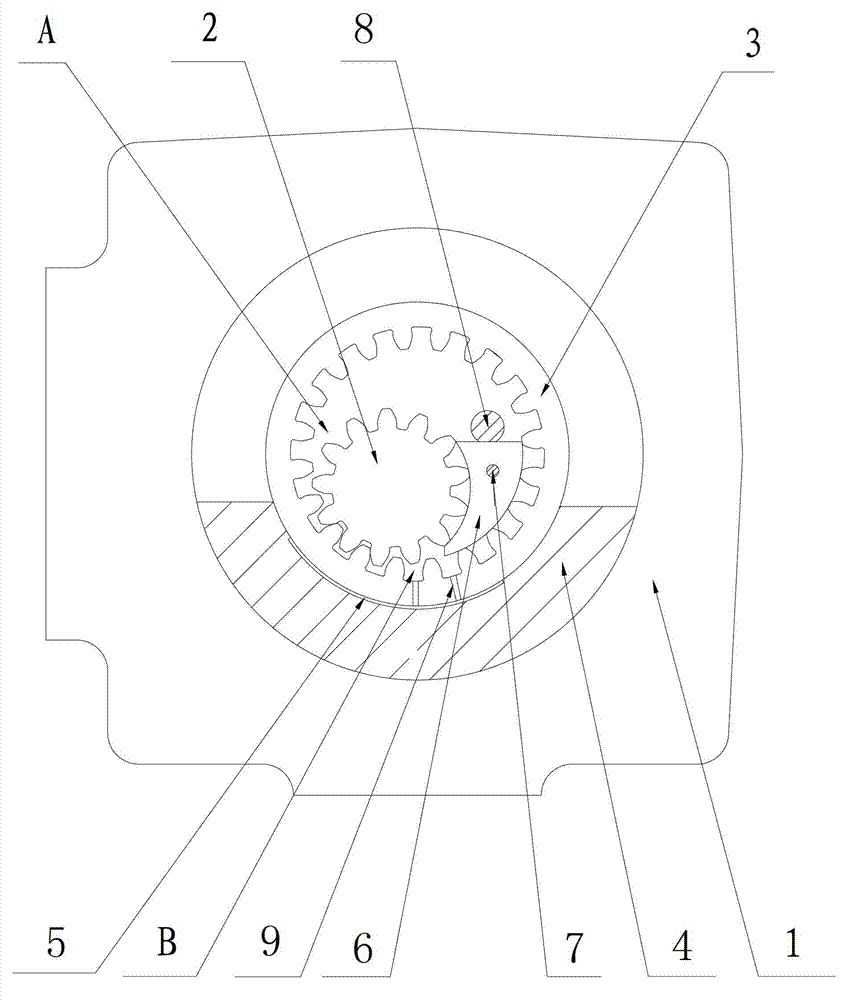

[0017] Example: Combining figure 1 As shown, the internal gear pump provided with a static pressure support device provided by the present invention has a pump body 1. The pump body 1 is provided with an external gear 2 and an internal gear 3 meshing on one side as in the conventional technology. , Both sides of the external gear 2 and the internal gear 3 are provided with floating side plates (not shown in the figure), the floating side plate is fixed with a crescent plate 6 through a guide pin 7, and the crescent plate 6 is located between the external gear 2 and the inner gear Between the gears 3 and divide the non-meshing area of the external gear 2 and the internal gear 3 into two spaces, the space where the two gears disengage is the oil suction area A, which is connected to the oil inlet on the pump body 1 (not shown in the figure) ) Is connected, and the space where the two gears tend to mesh is the oil pressure zone B, which is connected to the oil outlet (not shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com