Method for determining assembly reliability of detachable disc-drum rotor

A drum-shaped rotor and reliability technology, which is applied in the field of judging the reliability of the assembly of a detachable drum-shaped rotor, can solve the problem that the assembly reliability of the detachable drum-shaped rotor, the inconsistency of the changing process of the looseness, and the single The characteristic change trend is not monotonic, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

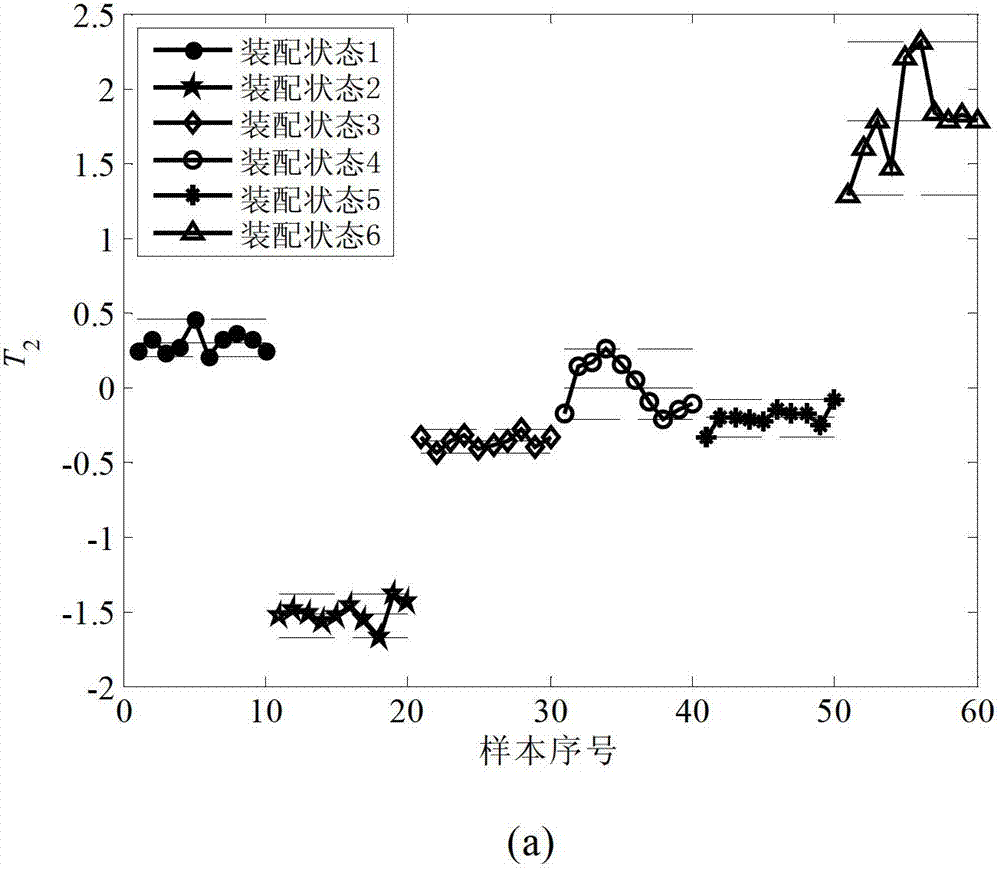

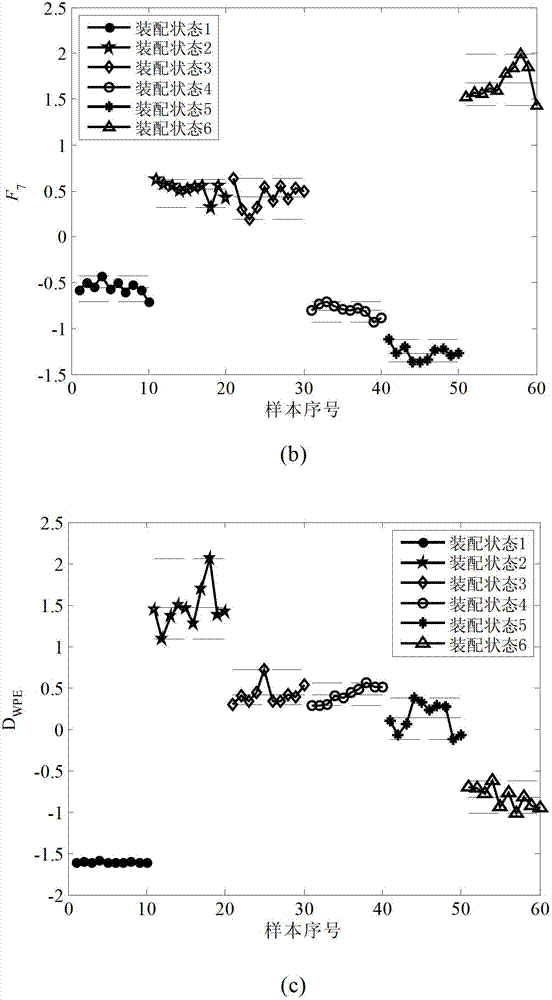

[0046] The method of the present invention obtains its dynamic response signal through the percussion test of the detachable disc-drum type rotor stand, extracts the time domain feature, frequency domain feature and wavelet domain feature of the dynamic response signal to form a state feature matrix; then establishes the orthogonal sub-matrix of the state feature matrix space; finally calculate the main included angle of the subspace base vector, and define a reliability index—the cosine value of the main included angle to determine the reliability of the rotor assembly.

[0047] The present invention is implemented according to the following specific steps:

[0048] 1) Construct the state feature matrix and establish the state feature matrix subspace

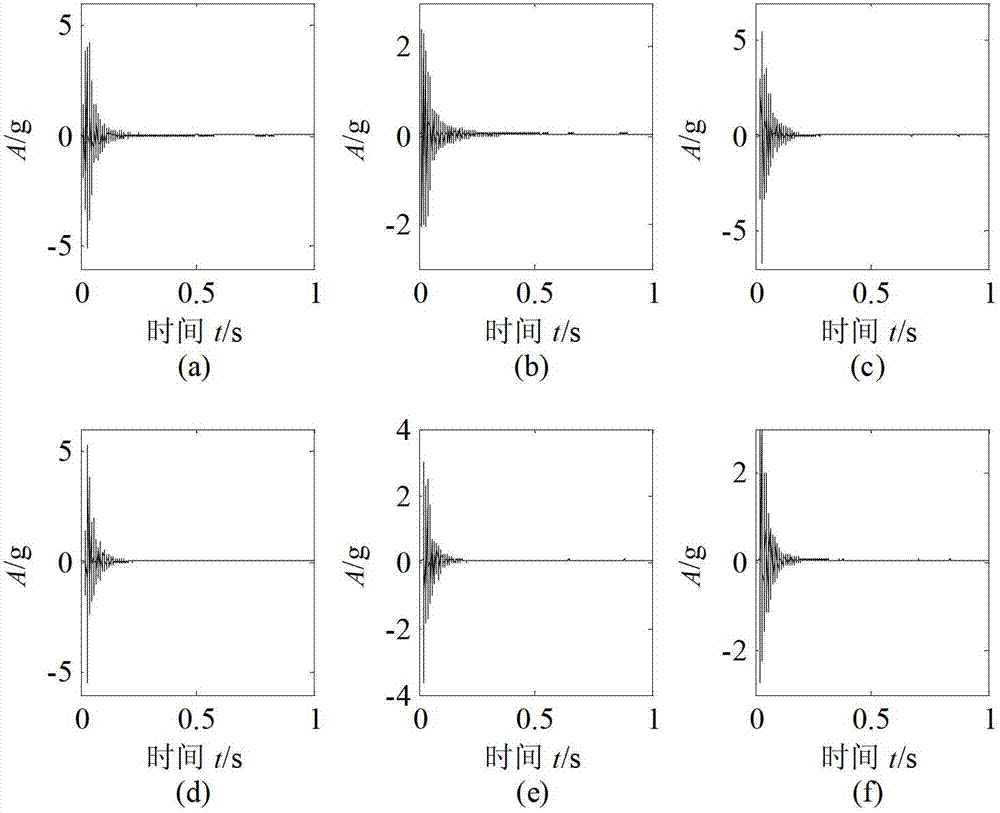

[0049] The bench knocking test was carried out on the detachable disc-drum rotor, and the dynamic response signals (good assembly state and unknown assembly state) of the detachable disc-drum rotor were collected by vibration a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com