Offline pretreatment device and method for simply measuring oxygen stable isotope ratio in water

A technology for stable isotope and water determination, which is used in measurement devices, material separation, instruments, etc., can solve the problems of small sample volume, difference in measurement results, and small reactor capacity, and achieves low cost, simple operation, and guaranteed determination. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

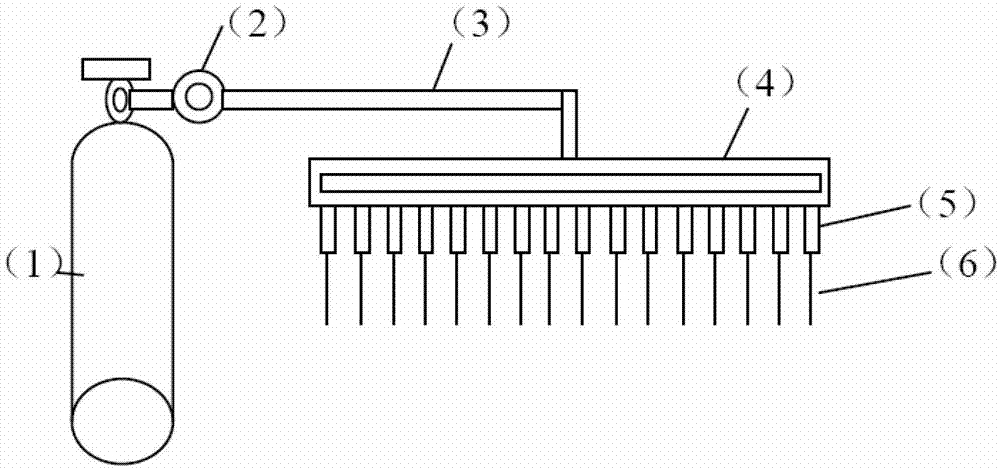

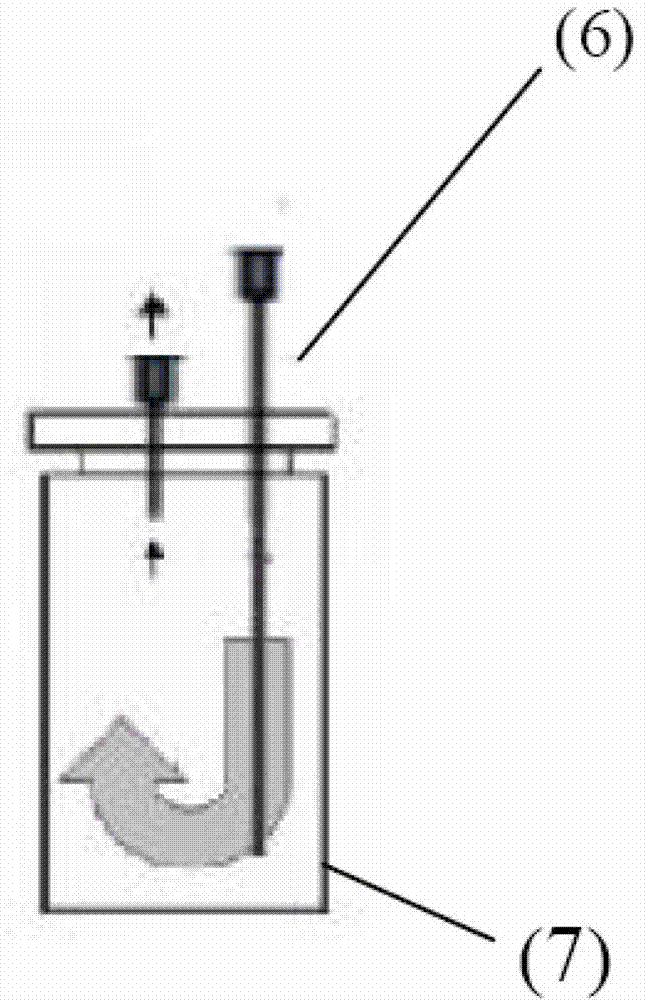

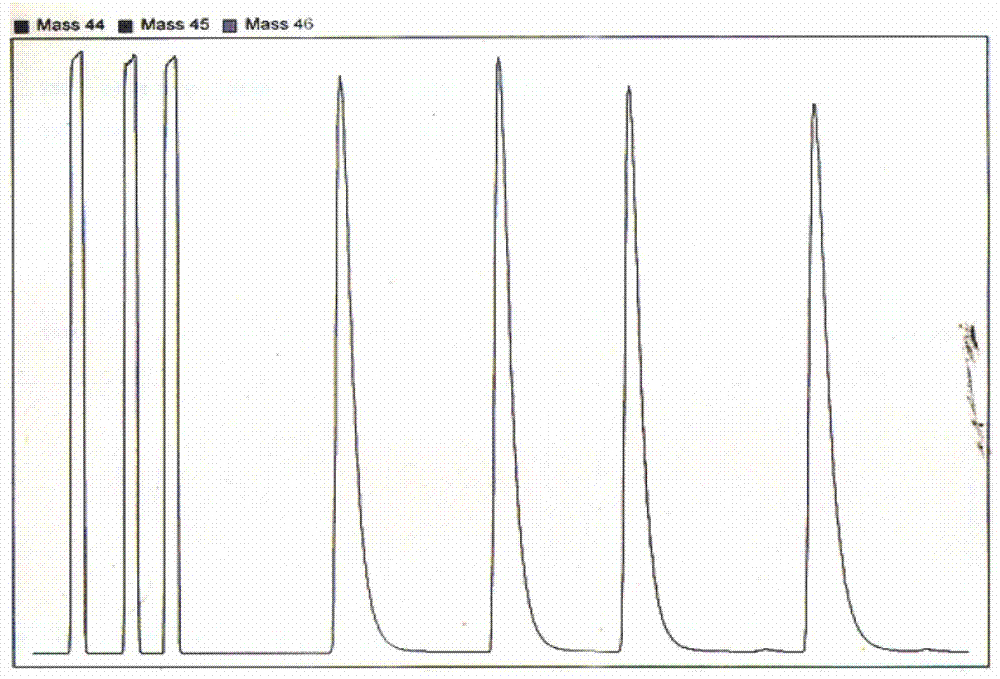

[0044] Combine now figure 1 , figure 2 and image 3 Describe the working process of the device and the analysis and measurement method.

[0045] 1. Add about 4mL of water sample to the reaction bottle (7), and cover it tightly with the cap (with Teflon gasket);

[0046] 2. Connect the reaction bottle (7) to the capillary stainless steel tube (6), open the valve of the carbon dioxide cylinder (1), open the pressure reducing valve (2), and replace the air in the reaction bottle with the upward exhaust method (such as figure 2 ), after 15 minutes, unplug the capillary stainless steel tube (6) from the reaction bottle (7);

[0047] 3. Put the reaction bottle in a water bath at 25±0.2°C, shake it for 10 hours and take it out;

[0048] 4. Set gas chromatography parameters: inlet temperature 100°C, column temperature 100°C, constant flow rate 1.2mL / min;

[0049] 5. Use a gas sampling needle to collect the gas in the reaction bottle (continuous collection by an automatic sample...

Embodiment 2

[0051] According to the method in Example 1, take a certain water sample as the experimental object, process and measure the δ in the water continuously 18 O(n=3), the results are shown in Table 1

[0052] Table 1 Repeated determination of a water sample δ 18 Result of O (‰)

[0053]

[0054] In this example, it has been verified that offline pretreatment device and assay method in the present invention measure δ in water 18 The repeatability of O, as can be seen from Table 1, the 1σ of the present invention is only 0.075‰, which is less than the international standard for water δ 18 Determination requirements of O (0.2‰)

Embodiment 3

[0056] With 4 known δ 18 The water samples of O (see Table 2) were the experimental objects, and the four samples were measured according to the method in Example 1, and the results are shown in Table 2.

[0057] Table 24 kinds of water samples δ 18 o

[0058]

[0059] As can be seen from Table 2, although there is a certain deviation between the measured result and the known value, the analysis data can find that the two are in a good linear relationship, see Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com