Support device for optical lens

An optical lens and support device technology, applied in optics, optical components, installation, etc., can solve the problems of easy scratching of optical lenses, difficult to remove optical lenses and frame tightly, difficult to remove optical lenses, etc., to achieve easy processing and manufacturing. , Simple structure, easy to disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

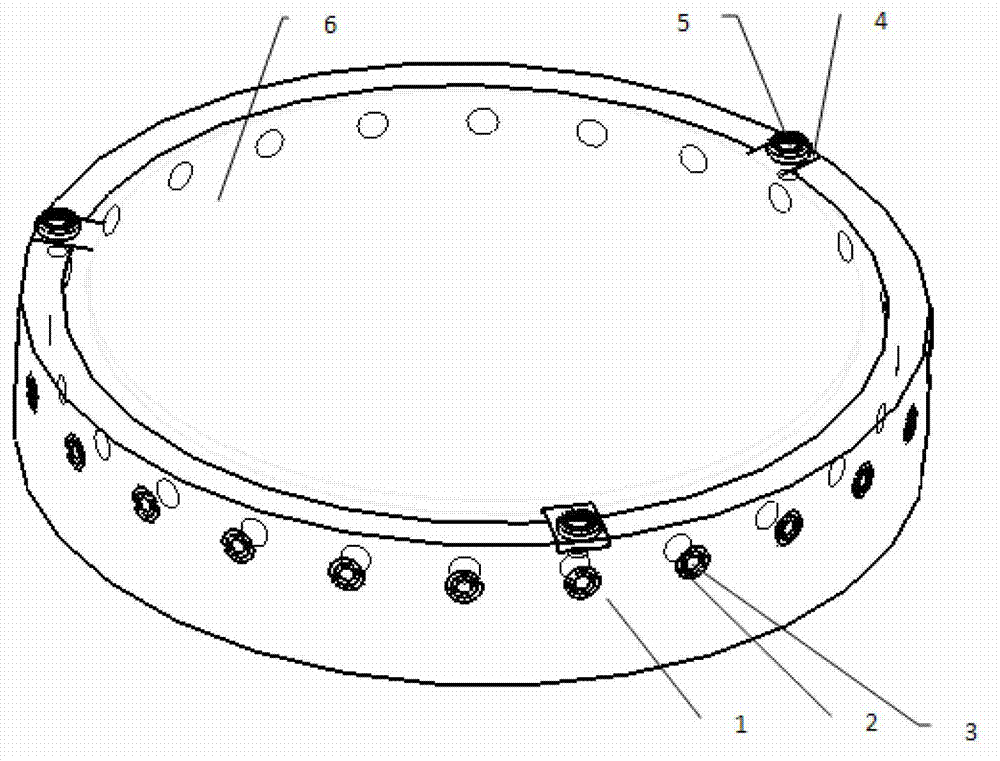

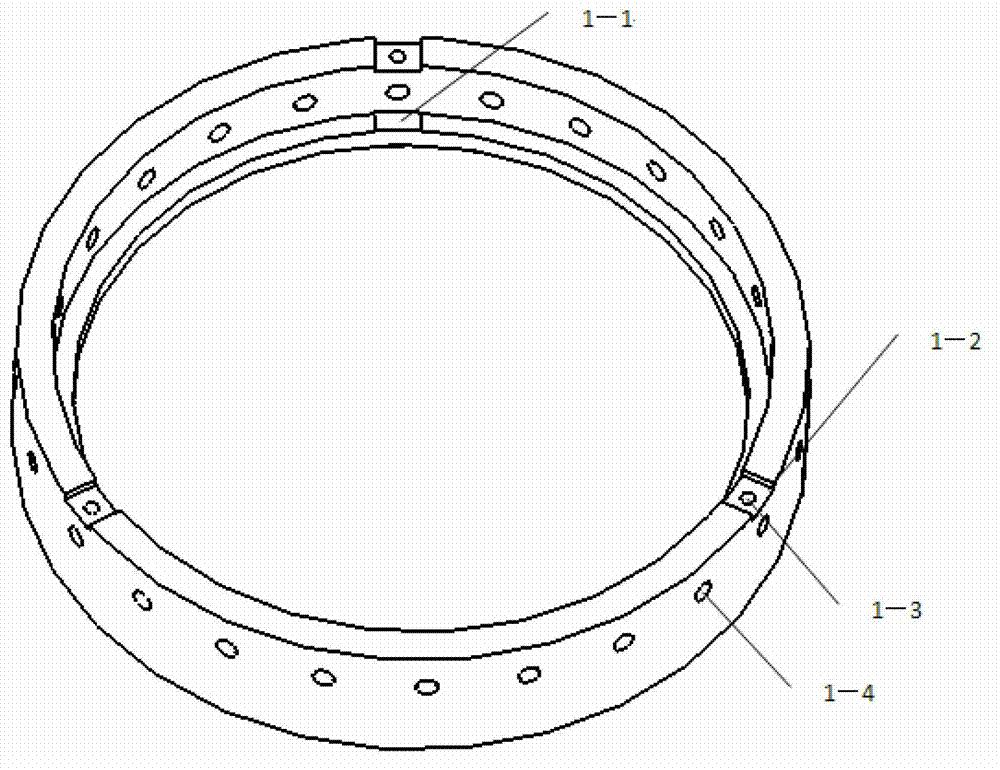

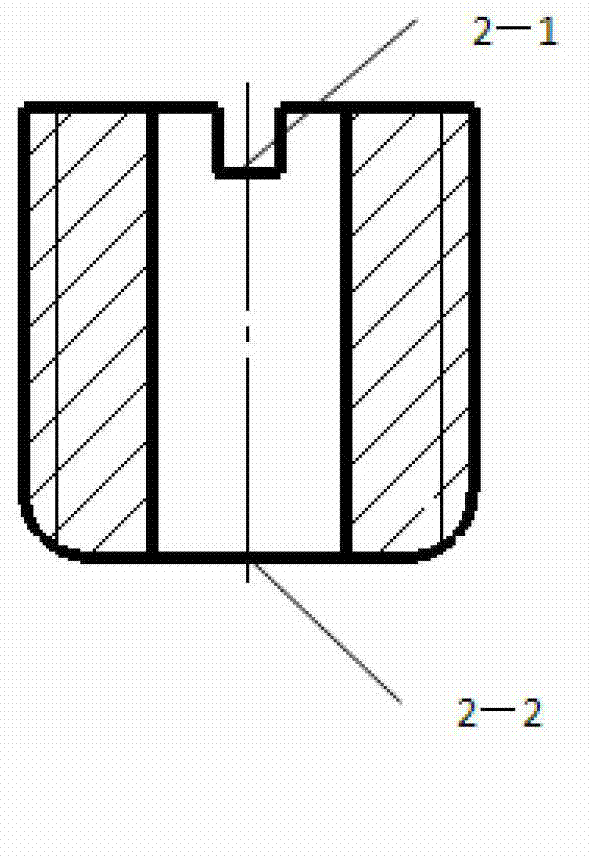

[0016] A supporting device for an optical lens, the device includes a frame 1, a hollow screw 2, an adhesive 3, an optical lens pressing block 4 and a connecting screw 5. The picture frame 1 described in the present embodiment is ring-shaped, and the material adopts the metal material with higher strength, can be aluminum, titanium alloy or stainless steel etc., and its inner circle diameter is greater than the diameter of optical lens 6, and inner circle diameter and optical lens 6 The diameter difference ranges from 0.03 to 0.5mm; there are three bosses 1-1 on the inner edge of the bottom of the frame 1 for supporting optical lenses, and the bosses 1-1 are evenly distributed around the circumference and are higher than the bottom of the frame 1 The inner edge is 0.5mm; the upper end surface of the picture frame 1 has t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com