Safe self-destruction type injector

A syringe and self-destruction technology, applied in the field of medical devices, can solve the problems of difficult manufacturing process, unsatisfactory effect, high material requirements, etc., and achieve the effects of low manufacturing process difficulty, easy promotion and reduction of process steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

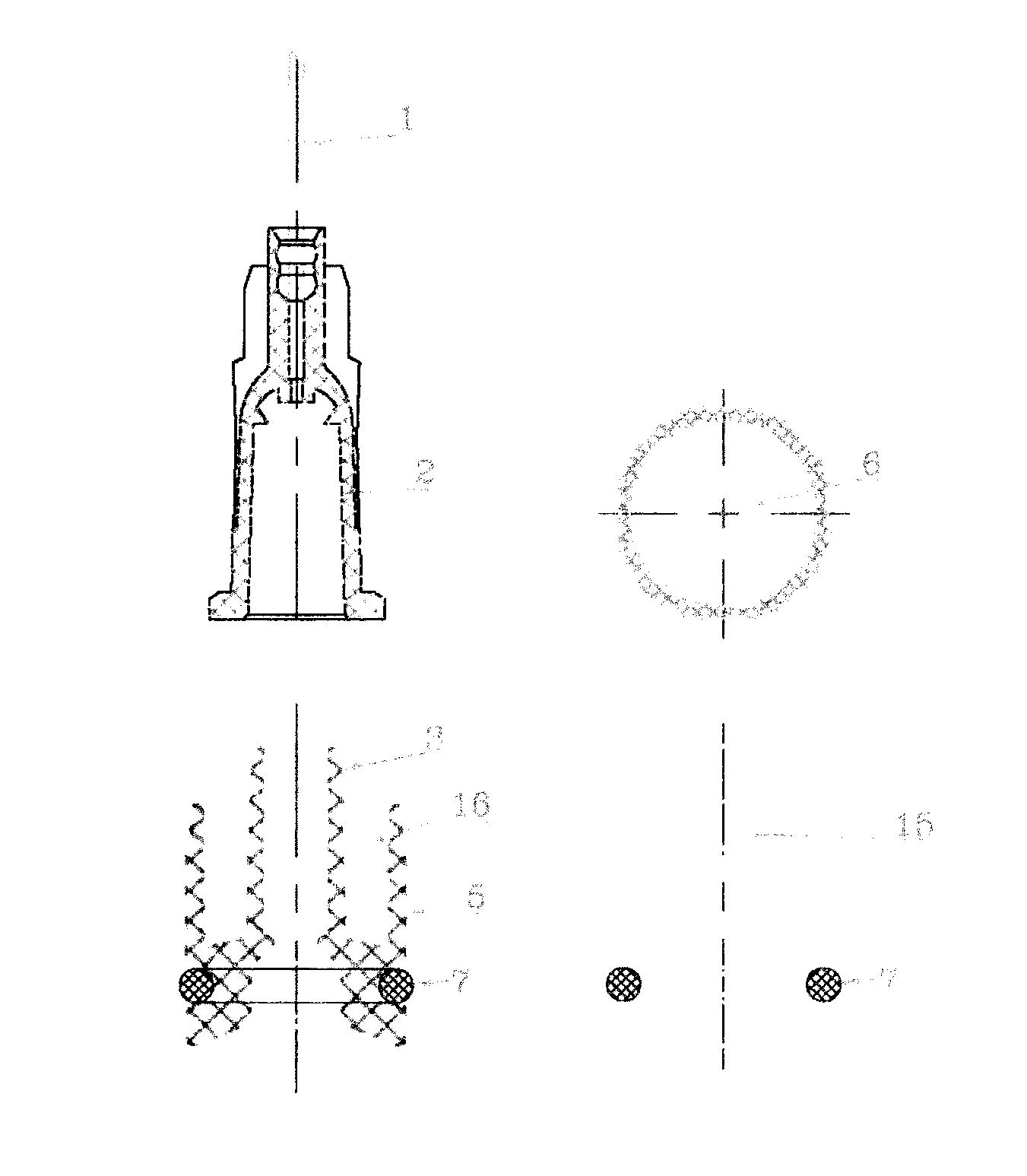

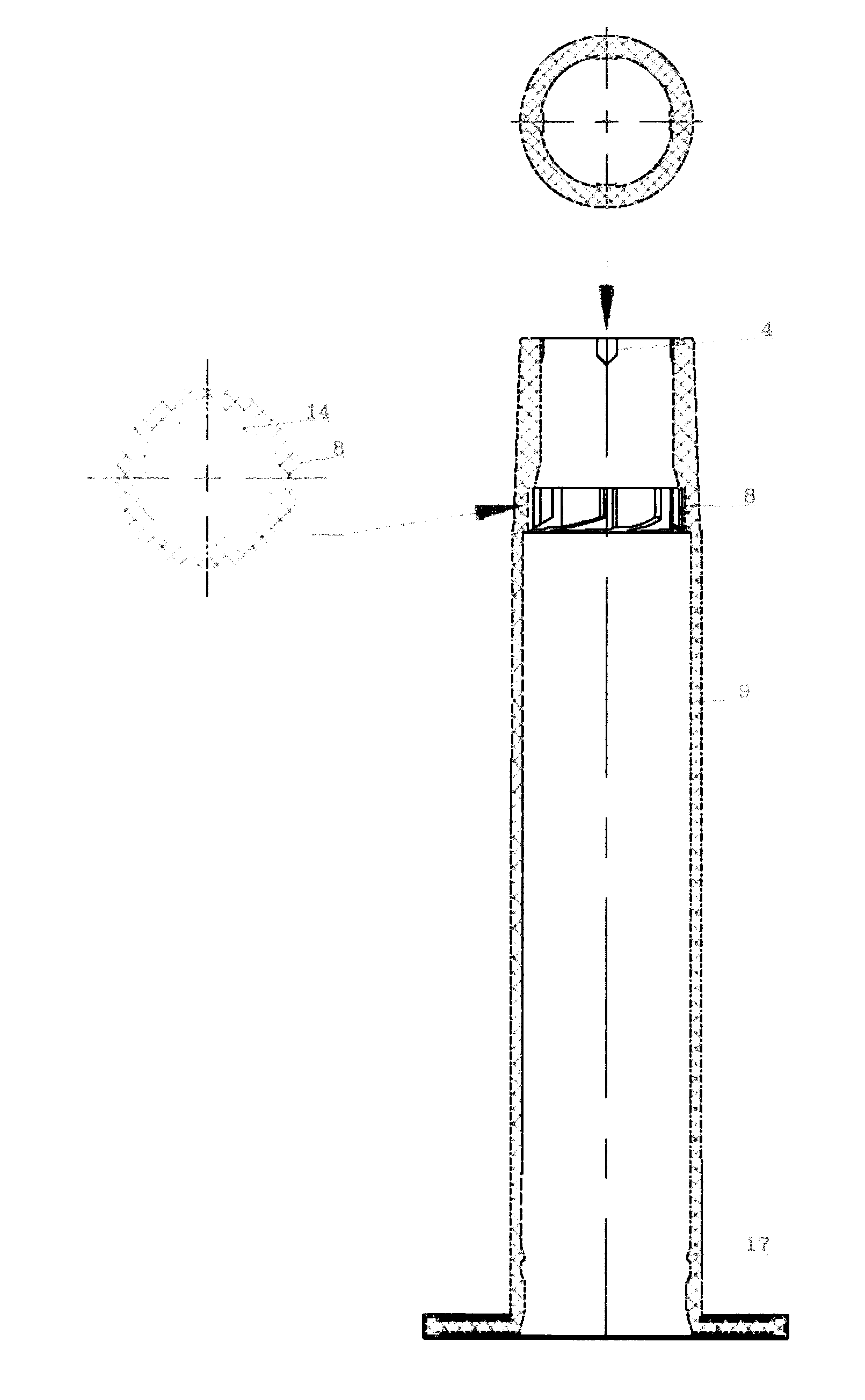

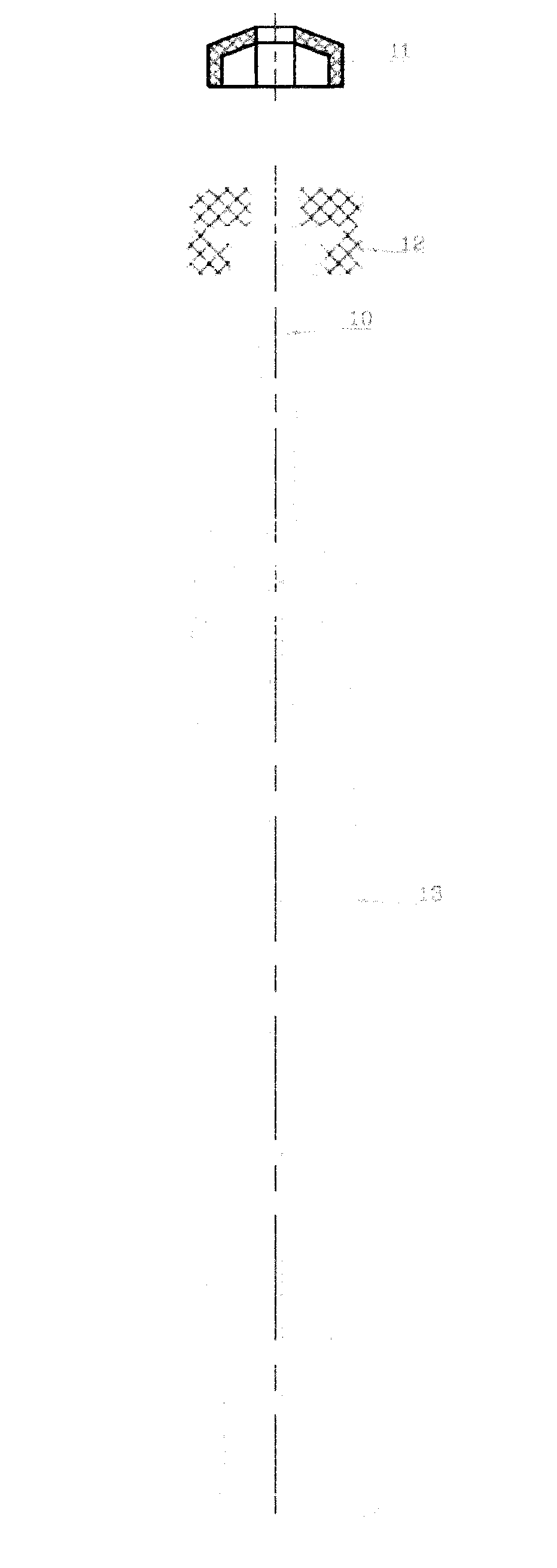

[0018] Below in conjunction with accompanying drawing and embodiment this patent is further described.

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown in: the present invention mainly includes an injection needle (1); a needle seat (2); a 6:100 tapered hole (3) on the replaceable needle seat; a fixed anti-slip strip (4) on the barrel; the replaceable needle Seat (5); pull-back piece (6) on the replaceable needle seat; sealing ring (7); cylinder neck (8); cylinder body (9); pull-back connecting column (10); piston fixing seat (11) ;piston (12); core rod (13); outer shrapnel (14); fixed anti-skid groove (15) on the replaceable needle seat; fixed thread (16) on the replaceable needle seat; The rod pushes back and pulls out the ring (17); the non-threaded replaceable needle seat (18); the fixed needle needle seat (19), which is different from the prior art in that:

[0020] (1), the cylinder neck (8) above the cylinder (9) is provided with an outer shrap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com