Medical full-automatic cleaning machine with floating ball valve

A fully automatic cleaning and floating ball valve technology, which is applied in the direction of engine components, control valve floats, valve operation/release devices, etc., can solve the problems of high cost of solenoid valves, easy failure of one-way mechanical valves, energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

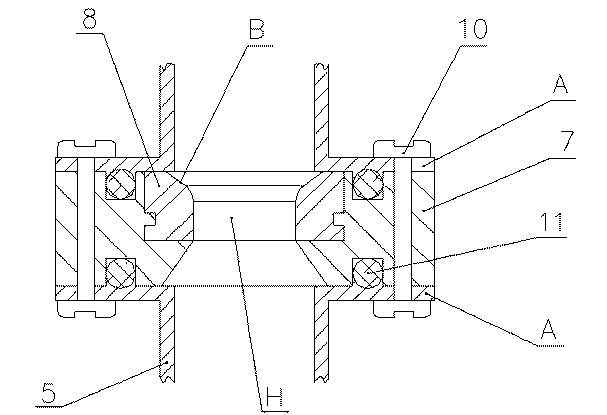

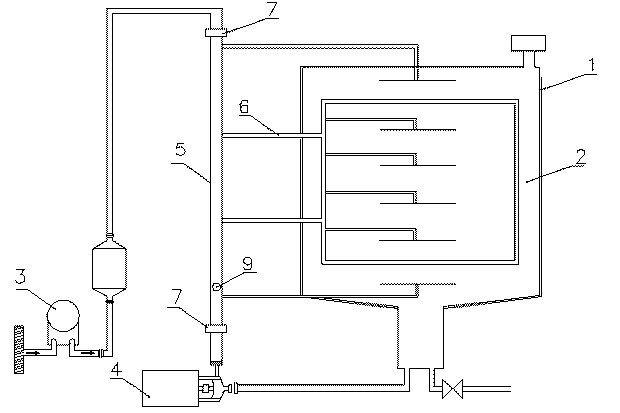

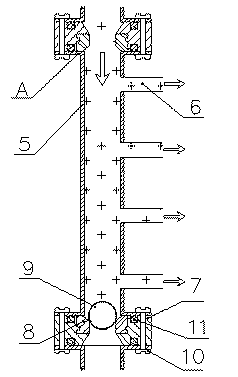

[0020] like Figure 1 to Figure 5 As shown, the first specific embodiment of the present invention is: a medical automatic cleaning machine with a float valve, comprising a frame 1, a cleaning chamber 2, an air pump 3, a water pump 4 and a main pipeline 5, the frame 1, Both the cleaning chamber 2 and the main pipeline 5 are made of stainless steel, and a cleaning frame is arranged in the cleaning chamber 2, and the main pipeline 5 is arranged outside the cleaning chamber 2 and vertically arranged on the frame 1 parallel to the side wall of the cleaning chamber. Both the air pump 3 and the water pump 4 are installed on the frame 1, the air pump 3 is connected to the upper end of the main pipeline 5, and the water pump 4 is connected to the lower end of the main pipeline and connected to the water tank below the cleaning chamber 2, and is installed on the cleaning chamber and the cleaning rack. A plurality of spouts are provided, and these spouts communicate with the main pipe 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com