Simple air cooling device for paraffin molding

A technology of air cooling device and water cooling device, which is applied to casting and molding equipment and other directions, can solve the problems of high maintenance cost, high production cost, large-scale equipment, etc., and achieve the effects of reducing production cost, low maintenance cost and easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

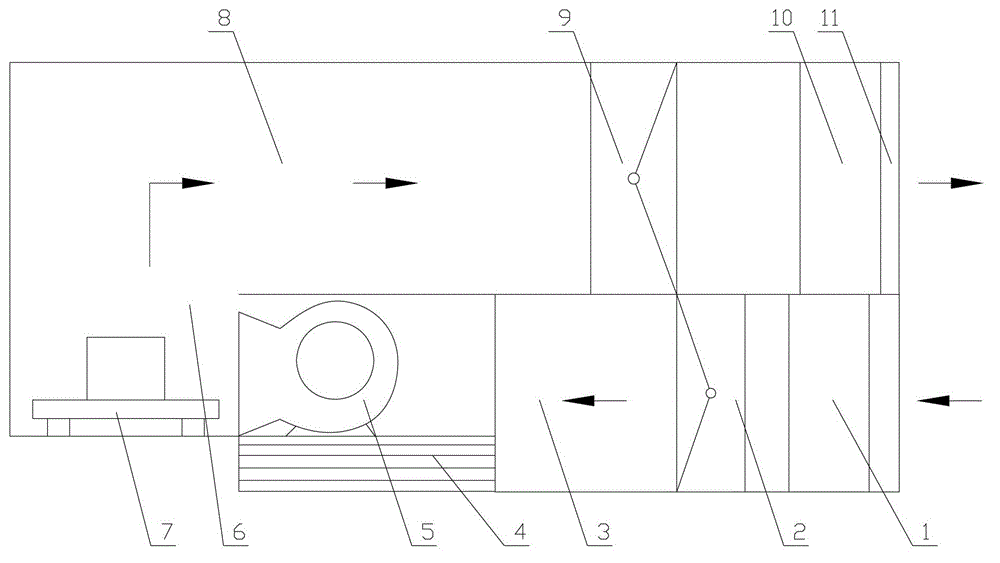

[0019] The specific embodiment of the present invention is shown in accompanying drawing, is made up of blower fan 5, conveying line 7 and water cooling device 4; It is characterized in that air exhaust tube 8 and air inlet tube 3 are installed up and down, and pass through the air cooling zone 6 at one end Connected and communicated; air inlet cylinder 3 is equipped with air valve and filter device 1, first one-way air valve 2 and fan 5 in sequence from the air inlet end to the end of air-cooling area 6; second one-way air valve is installed in exhaust cylinder 8 9 and air exhaust device 10, air valve and protective net 11 are housed at the outlet of air exhaust tube 8.

[0020] The bottom of the fan 5 is equipped with a water cooling device 4 .

[0021] A conveying line 7 is housed in the air-cooling zone 6, and the paraffin material blocks conveyed on the conveying line 7 are placed at the air outlet of the blower fan 5.

[0022] The above is only a preferred embodiment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com