Electric vehicle chassis system and collaborative control method thereof

An electric vehicle and vehicle braking technology, applied in the field of electric vehicle chassis system and its collaborative control, can solve the problems of complex controller design, difficult to guarantee the overall reliability, shortening the development time of the controller and the difficulty of development, so as to improve the smooth driving sex, reducing conflicting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

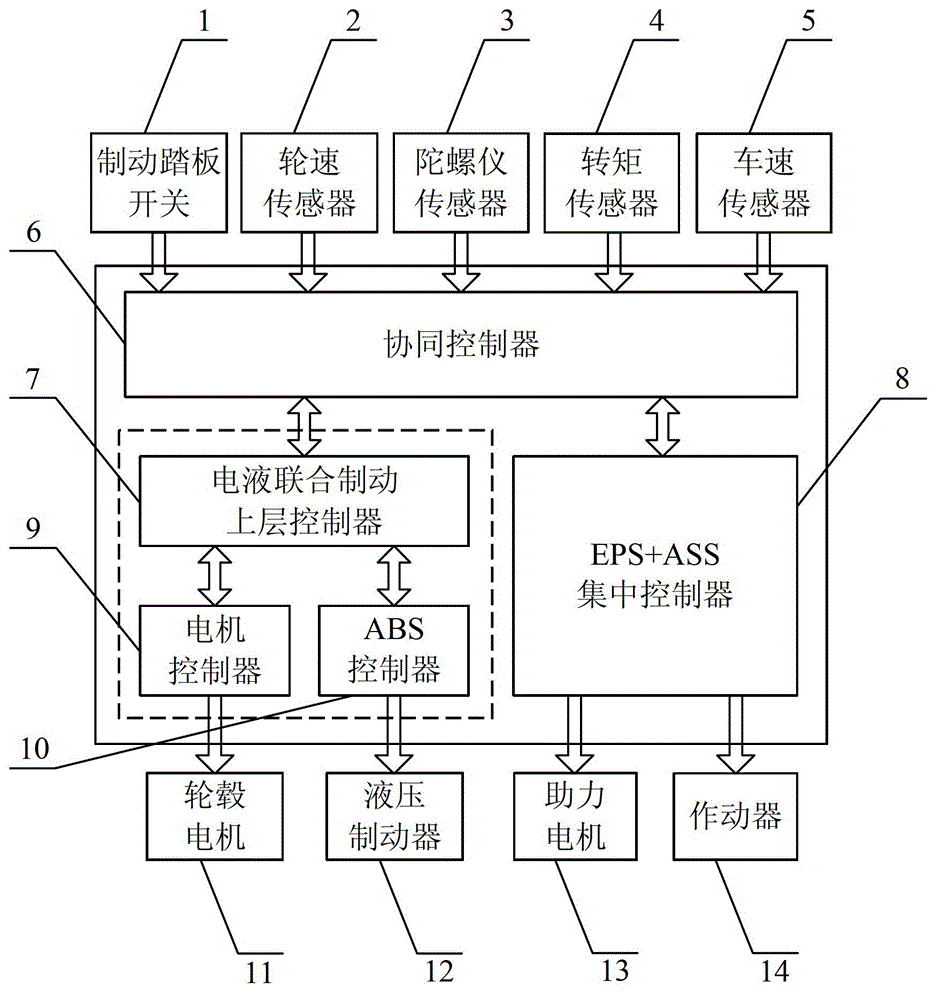

[0011] The present embodiment will be further described in conjunction with FIG. 1 .

[0012] The electric vehicle chassis system of the present invention is composed of EPS, ASS, ABS and motor braking system, which respectively represent the three subsystems of steering system, suspension system and braking system in the electric vehicle chassis system.

[0013] In the present invention, the brake pedal switch 1 generates a brake trigger signal, the wheel speed sensor 2 measures the wheel speed signal, and the gyro sensor 3 measures the vertical acceleration, longitudinal acceleration, lateral acceleration, pitch angle, roll angle and The yaw rate signal, the torque sensor 4 measures the steering shaft input torque signal, the vehicle speed sensor 5 measures the vehicle speed signal, and the above sensor signals are transmitted to the cooperative controller 6; the cooperative controller 6 transmits the brake trigger signal, wheel speed signal, The vehicle speed signal and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com