Temporary storage device for ceramic tiles

A technology for ceramic tiles and brick racks, which is applied in the field of ceramic tile temporary storage machinery, can solve problems such as affecting production efficiency and different processes of ceramic tile production lines, and achieves the effect of improving production efficiency and solving asynchronous problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

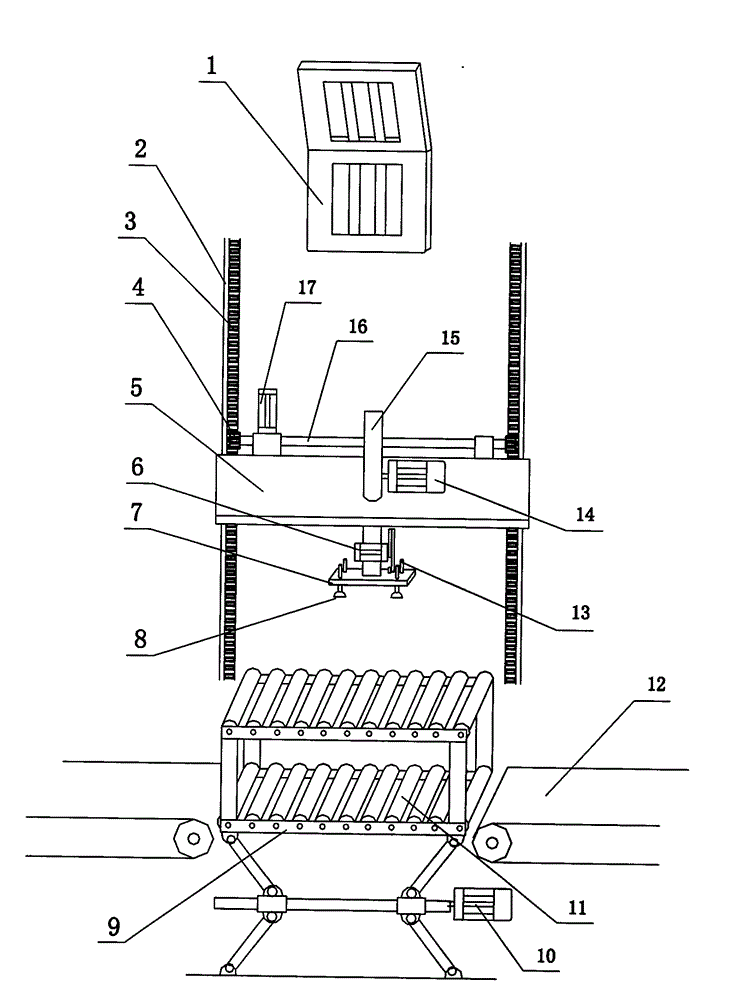

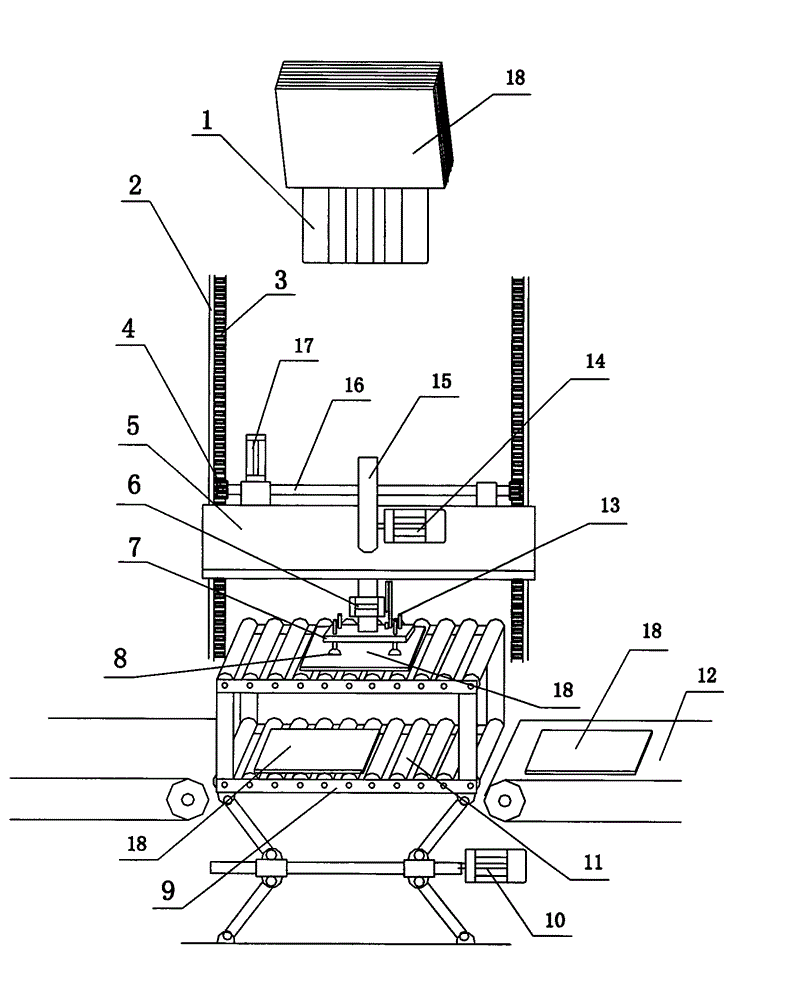

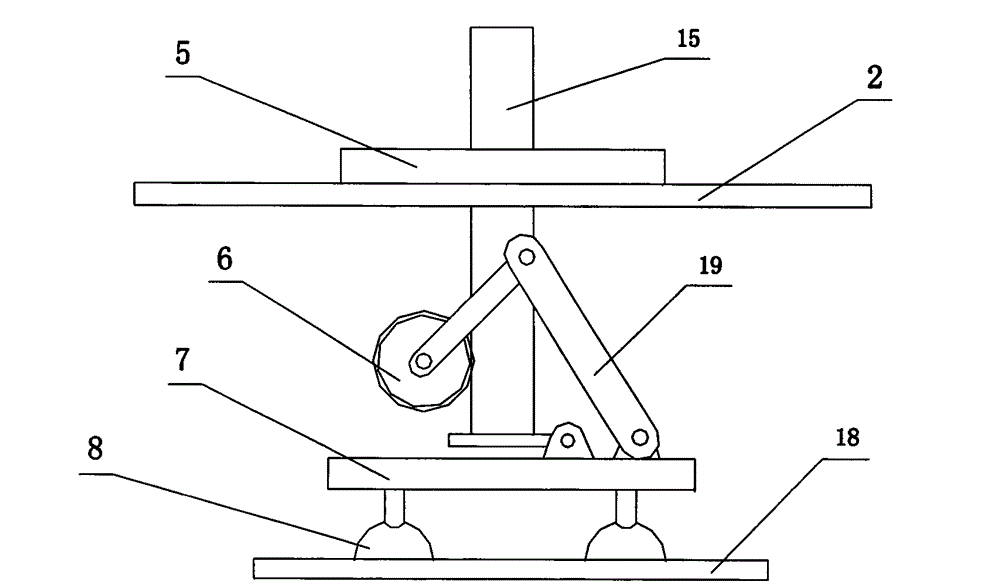

[0031] like figure 1 , figure 2 , image 3 , Figure 4 As shown, a tile temporary storage device includes a brick frame 1, a mobile platform 5, a suction cup 8, a lifting platform 9 and a conveyor belt 12. A lifting platform 9 is set between the conveyor belts 12 on the ceramic tile production line. Two layers of rotating rollers 11 are installed on the lifting platform 9. The lifting platform 9 can rise and fall under the drive of the motor 10. When the lifting platform 9 rises, the bottom layer of rotating rollers 11 is flush with the conveyor belt 12, does not affect the passage of the tiles 18 on the conveyor belt 12. When the lifting platform 9 descends, the upper layer of rotating roller 11 is flush with the conveyor belt 12, and when the ceramic tile 18 arrives on the lifting platform 9, the brick blocking plate blocks the passage of the ceramic tile 18, and then the lifting platform 9 rises. A pair of guide rails 2 are installed perpendicular to the conveyor belt ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap