Granulated magnesium molten iron desulfurization lance

A technology of molten iron desulfurization and granular magnesium, applied in the field of granular magnesium molten iron desulfurization spray gun, can solve the problems of uneven distribution of bubbles, low desulfurization efficiency, large magnesium consumption, etc., and achieve uniform distribution, high desulfurization efficiency, and low magnesium consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

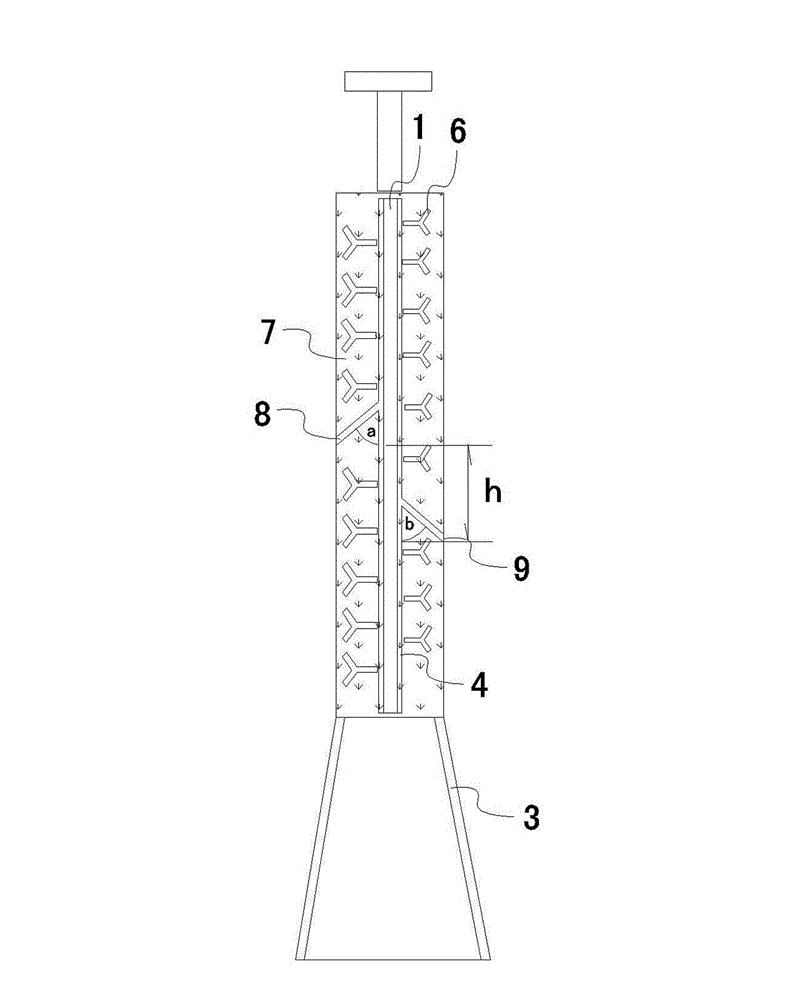

[0012] As shown in the figure, the granular magnesium molten iron desulfurization spray gun includes a gun body; the gun body includes a carrier gas nozzle 4, a refractory material layer 7, a skeleton 6 and a central nozzle 1; There is a vaporization chamber 3; the central nozzle 1 is set in the carrier gas nozzle 4; the lower port of the central nozzle 1 communicates with the vaporization chamber 3; the refractory material layer 7 is located outside the carrier gas nozzle 4; The skeleton 6 is placed in the refractory material layer 7 and is fixedly connected with the carrier gas nozzle 4; the first carrier gas tail nozzle 8 and the second carrier gas nozzle 4 are fixedly arranged in different longitudinal sections of the carrier gas nozzle 4. Gas tail nozzle 9; the distance between the lower ends of the first carrier gas tail nozzle 8 and the second carrier gas tail nozzle 9 is h=31cm.

[0013] As a preferred solution, the longitudinal deflection angle a of the first carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com