Chemical vapor deposition device used for flat-panel display

A chemical vapor deposition, flat panel display technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of dead space increasing device occupied area, large dead space, confusion and other problems, and achieve improved deposition quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

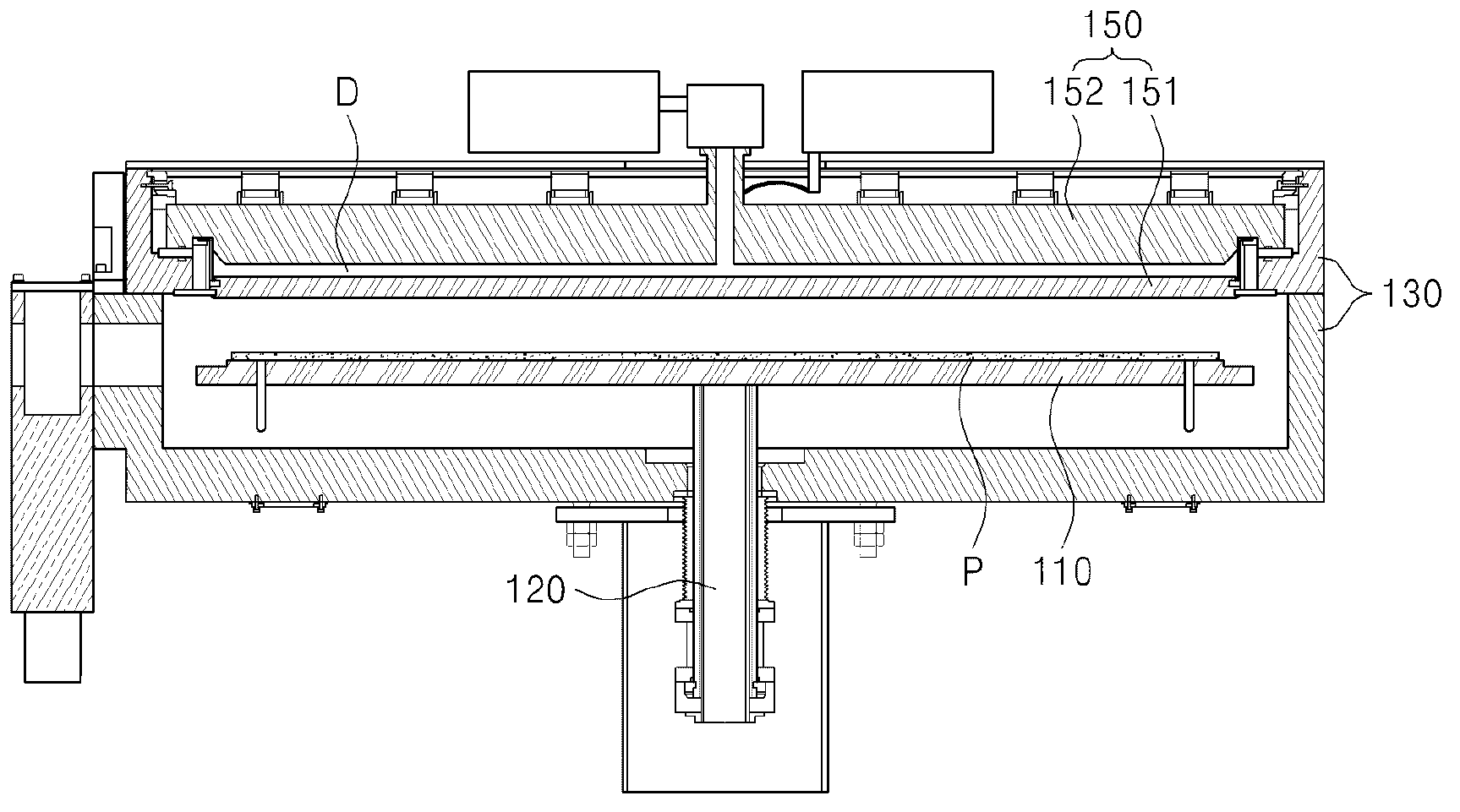

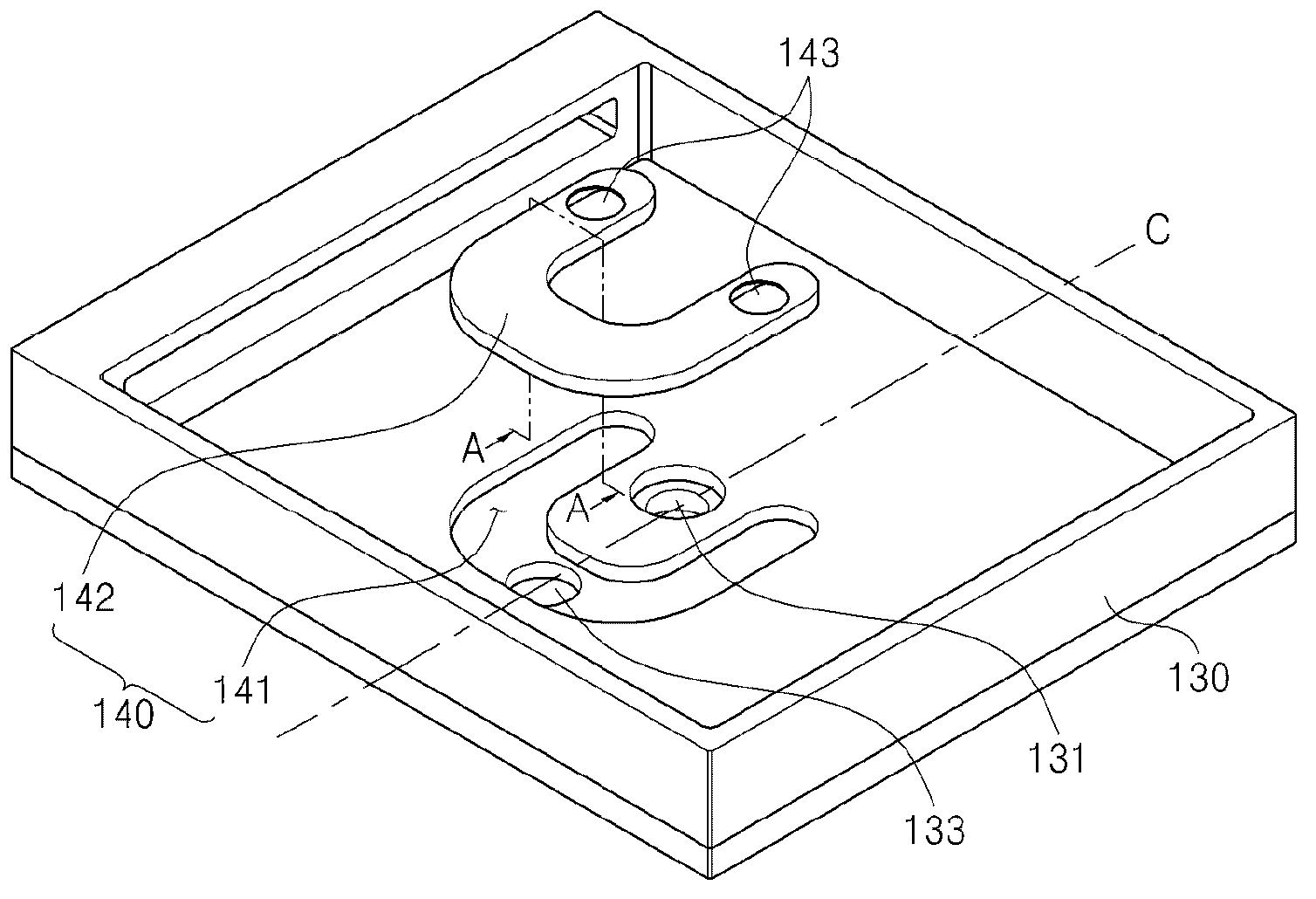

[0131] In order to fully understand the present invention and its advantages, reference is now made to the accompanying drawings, which illustrate various embodiments of the invention.

[0132] Hereinafter, the present invention will be explained in detail by explaining embodiments of the invention with reference to the accompanying drawings. Like reference numbers in the figures indicate like elements.

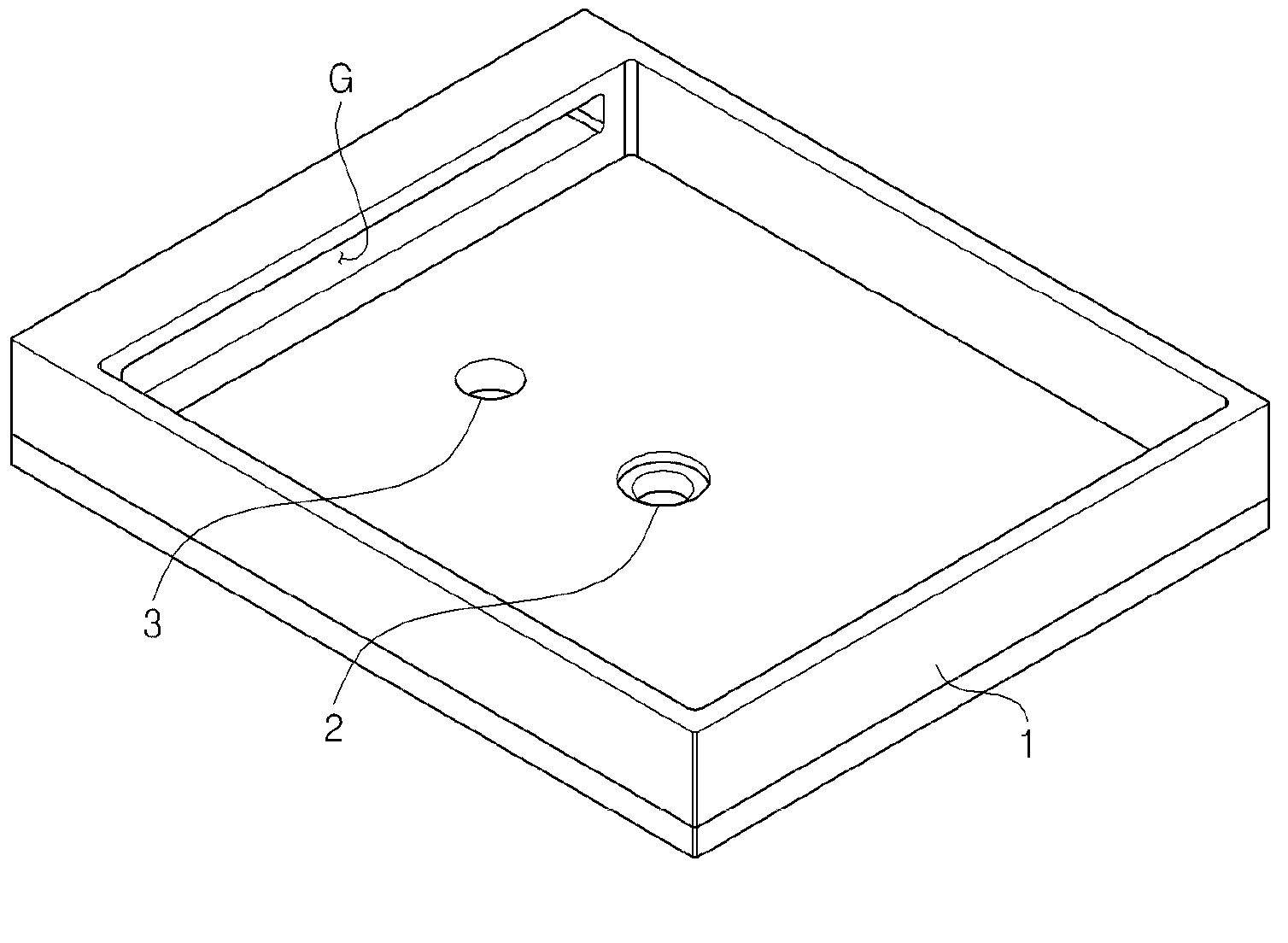

[0133] Before describing with reference to the accompanying drawings, a flat panel display to be described below may include any one of a liquid crystal display (LCD), a plasma display panel (PDP), and an organic light emitting diode (OLED).

[0134] However, in the following exemplary embodiments, a large glass substrate for an OLED will be considered as a flat panel display by way of example. In addition, "large" refers to a size of about 3 meters in width and length for the 11th generation substrate.

[0135] For convenience, a large glass substrate for OLED will be simp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com