Manufacturing device and method of diamond film

A diamond film and preparation device technology, which is applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems of low preparation efficiency and poor preparation quality, and achieve increased deposition speed, improved deposition quality, and improved The effect of preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

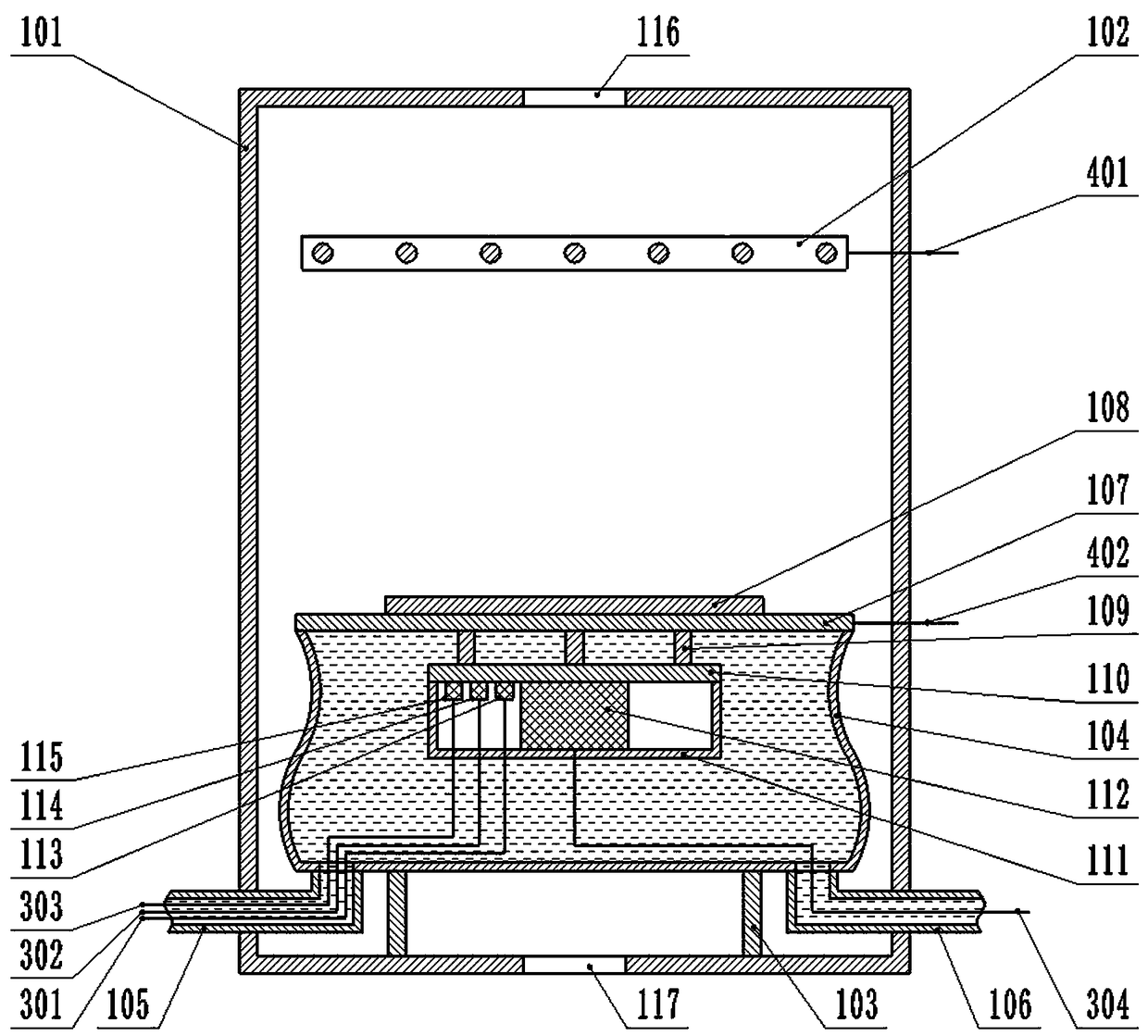

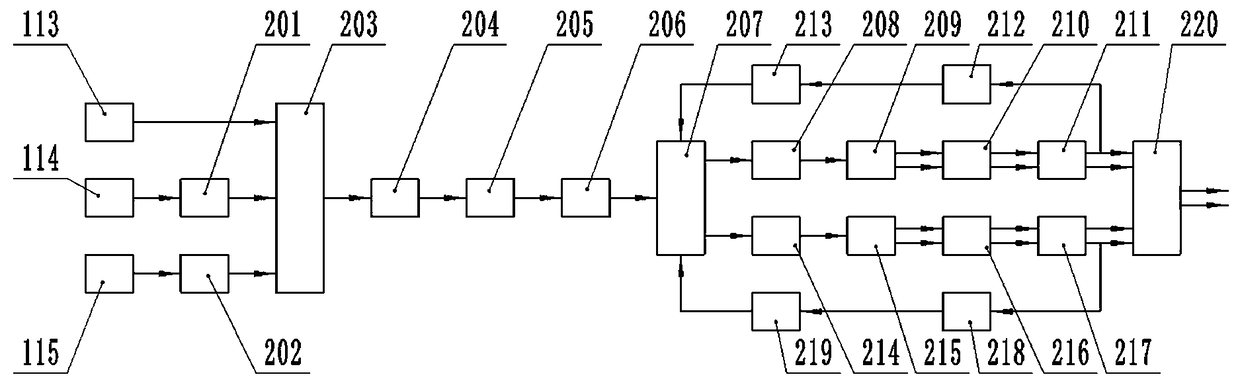

[0020] A device for preparing a diamond film, including a main body and a control part;

[0021] The main part includes a vacuum reaction chamber 101, a hot wire array 102, a support column 103, a cup-shaped water cooling chamber 104, a water inlet pipe 105, a water outlet pipe 106, a metal cooling plate 107, a substrate 108, a transmission column 109, a transmission plate 110, Waterproof cooling cover 111, ultrasonic transducer 112, speed sensor 113, displacement sensor 114, acceleration sensor 115;

[0022]The center of the top wall of the vacuum reaction chamber 101 is provided with an air inlet 116; the center of the bottom wall of the vacuum reaction chamber 101 is provided with an air outlet 117; the hot wire array 102 is installed horizontally on the upper part of the inner cavity of the vacuum reaction chamber 101; the support column 103 The number is several; each supporting column 103 is vertically fixed on the inner bottom wall of the vacuum reaction chamber 101; th...

Embodiment 2

[0035] A diamond film preparation device, including a main part and a control part;

[0036] The main part includes a vacuum reaction chamber 101, a hot wire array 102, a support column 103, a cup-shaped water cooling chamber 104, a water inlet pipe 105, a water outlet pipe 106, a metal cooling plate 107, a substrate 108, a transmission column 109, a transmission plate 110, Waterproof cooling cover 111, ultrasonic transducer 112, speed sensor 113, displacement sensor 114, acceleration sensor 115;

[0037]The center of the top wall of the vacuum reaction chamber 101 is provided with an air inlet 116; the center of the bottom wall of the vacuum reaction chamber 101 is provided with an air outlet 117; the hot wire array 102 is installed horizontally on the upper part of the inner cavity of the vacuum reaction chamber 101; the support column 103 The number is several; each supporting column 103 is vertically fixed on the inner bottom wall of the vacuum reaction chamber 101; the cu...

Embodiment 3

[0050] A diamond film preparation device, including a main part and a control part;

[0051] The main part includes a vacuum reaction chamber 101, a hot wire array 102, a support column 103, a cup-shaped water cooling chamber 104, a water inlet pipe 105, a water outlet pipe 106, a metal cooling plate 107, a substrate 108, a transmission column 109, a transmission plate 110, Waterproof cooling cover 111, ultrasonic transducer 112, speed sensor 113, displacement sensor 114, acceleration sensor 115;

[0052]The center of the top wall of the vacuum reaction chamber 101 is provided with an air inlet 116; the center of the bottom wall of the vacuum reaction chamber 101 is provided with an air outlet 117; the hot wire array 102 is installed horizontally on the upper part of the inner cavity of the vacuum reaction chamber 101; the support column 103 The number is several; each supporting column 103 is vertically fixed on the inner bottom wall of the vacuum reaction chamber 101; the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com