A method for depositing polysilicon by lpcvd

A polysilicon, deposition temperature technology, applied in polycrystalline material growth, chemical instruments and methods, crystal growth, etc., can solve the bipolar circuit compatibility can not meet the needs of the application, the maintenance cycle slows down the production capacity of the semiconductor process, and can not eliminate defects impact and other issues, to achieve the effect of improving production efficiency, increasing maintenance cycle, and increasing deposition quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

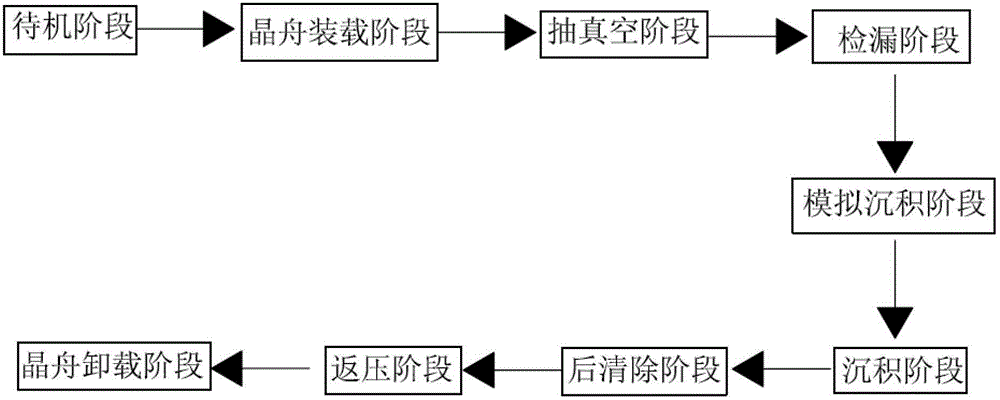

[0022] In order to clearly illustrate the improvement of the present invention, it is necessary to briefly introduce the existing LPCVD process. See figure 2 , figure 2 It is the existing LPCVD process flow chart. As shown in the figure, a deposition process is divided into the following stages: standby stage, crystal boat loading stage, vacuuming stage, leak detection stage, simulated deposition stage, and deposition stage , post purge phase, back pressure phase and wafer boat unloading phase. In the above-mentioned stages, considering the stability of the process, the temperature is set to be constant, that is, the temperature in the inner tube is the same temperature from the beginning to the end of the standby stage. What is changed is the pressure parameter of the inner tube and the flow rate and type of the gas.

[0023] The inventor's research has found that the existing LPCVD can easily lead to the deposition of particles on the inner tube wall for the following r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com