Piece bundle combination machine

A combined machine and machine head technology, applied in textile processing machine accessories, textiles and papermaking, textile material processing and other directions, can solve the problems of uneven pressure of the yarn sheet, the difference between the pressure area and the edge of the yarn sheet, etc., to achieve uniform pressure, The effect of good drying rate and less labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

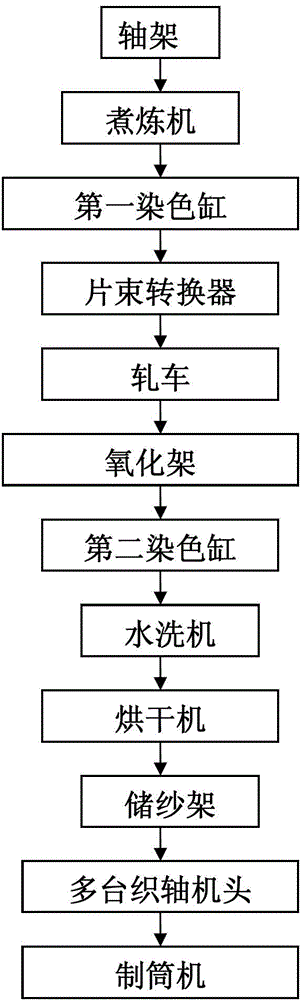

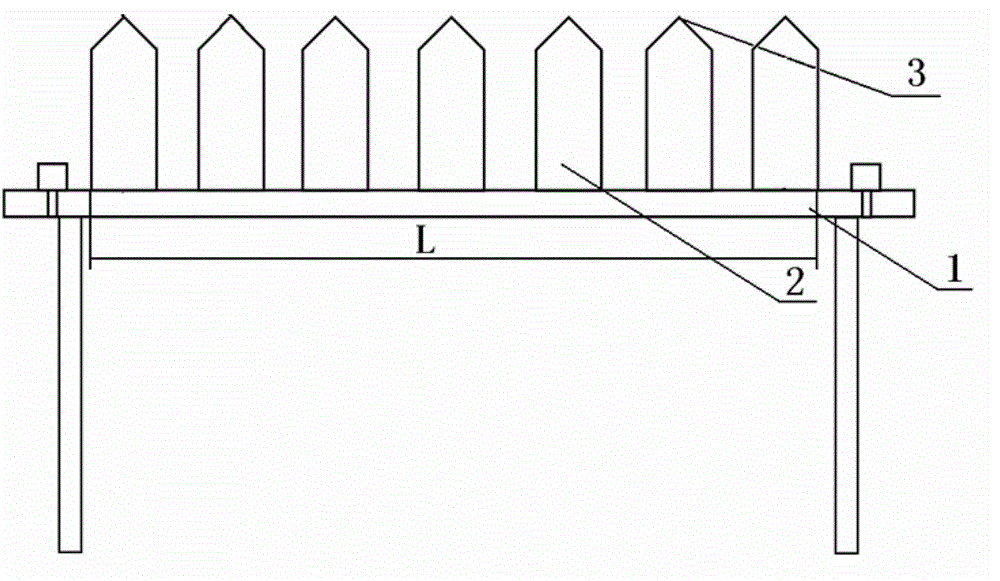

[0021] Such as figure 1 , 2 As shown, a sheet-bundle combining machine includes a creel, a scouring machine, a first dyeing vat, a padding car, an oxidation frame, a second dyeing vat, a washing machine, a dryer, a yarn storage rack, a weaving machine A shaft frame head and a tube making machine, the said weaving shaft frame head is a plurality of front cars, and a sheet bundle converter is arranged between the first dyeing vat and the padding car, and the sheet bundle converter is used to convert the sheet into The bundled yarn sheet is converted into a bundled yarn, which includes a base plate 1 and a partition plate 2 arranged at fixed intervals on the base plate 1, and the bundled yarn is naturally recovered into a sheeted yarn sheet on an oxidation rack.

[0022] The sheet-bundle converter is mainly to convert the sheet-shaped yarn sheet into a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com