Bored pile platform construction method on covering-free steep bare rock in deepwater and rapid stream

A technology without covering layer and construction method, applied in water conservancy projects, artificial islands, sheet pile walls, etc., can solve the problems of large workload, long construction period, high cost, etc., and achieve low cost, short construction period, and reduced work. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

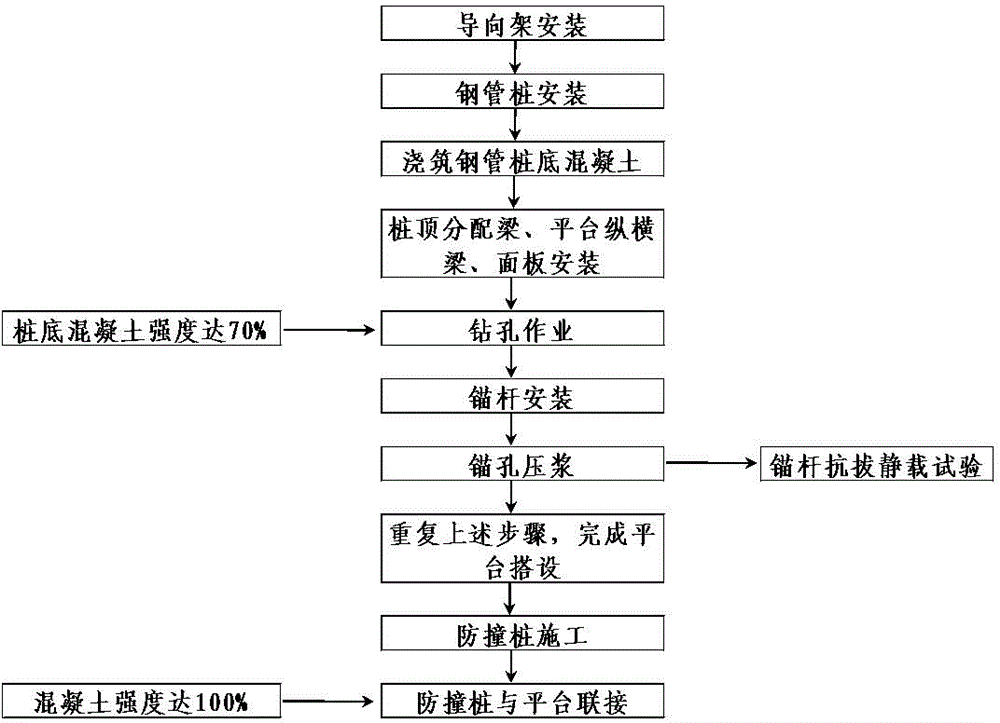

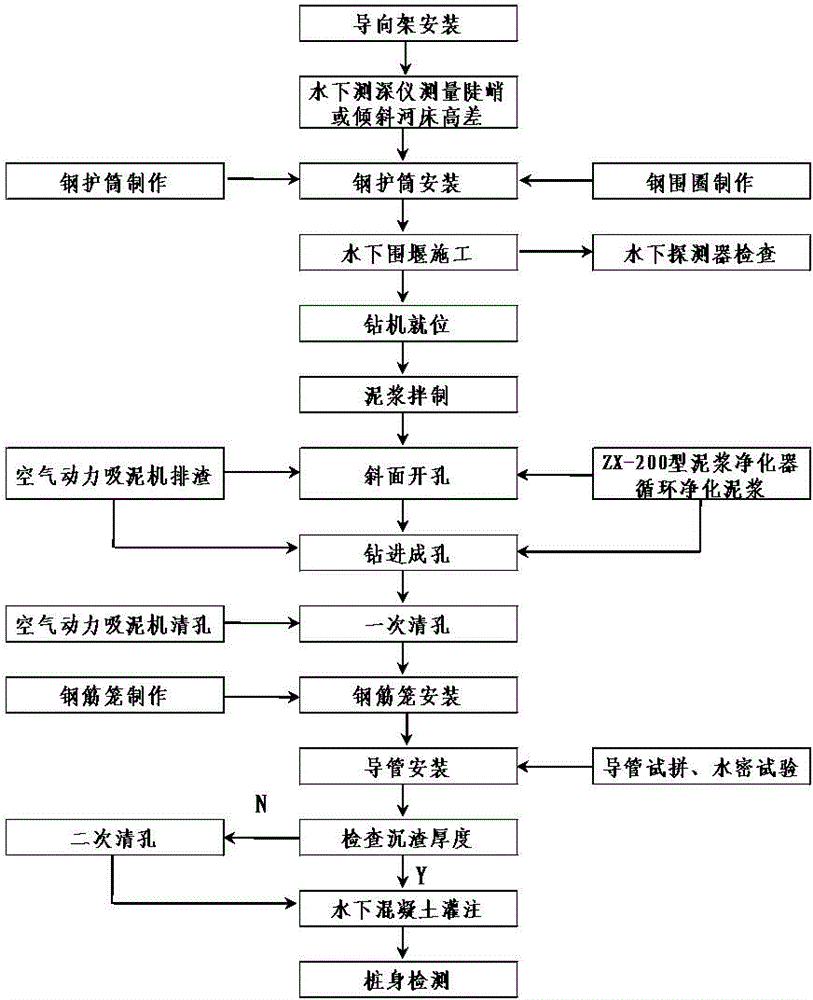

Method used

Image

Examples

Embodiment

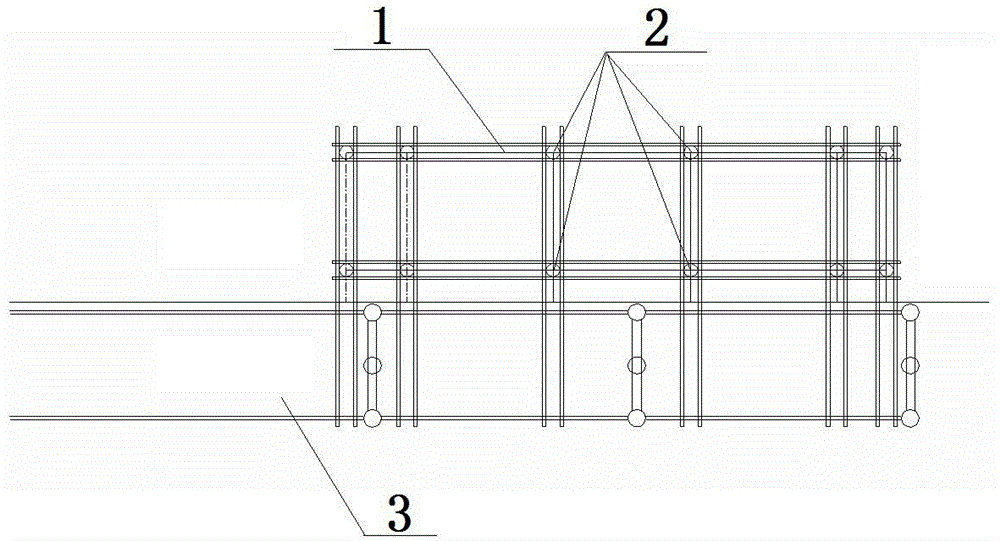

[0039]Embodiment: This embodiment specifically relates to a construction method of a bored pile platform on steep bare rock without covering layer in deep-water rapids. This embodiment will take the Qianjiang Super Bridge Project as an example to describe in detail. The project is located in Qianjiang, Guangxi, where the river is deep and the water is fast. ° between different; the main bridge is a 106+200+106m three-span prestressed concrete continuous rigid frame, 3#, 4# piers are continuous rigid frame main piers in the water, the two piers have the same structure, and the caps have a spindle-shaped outline , 3 rows of 15 φ2.5m rock-socketed bored piles are arranged in each pier. The pile foundation is required to be embedded in complete moderately weathered dolomite (frk=80MPa) not less than 10m, and underwater C40 concrete is used.

[0040] The bored pile platform in this embodiment specifically includes a framed platform and a steel casing for bored piles, and a framed d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com