Method for accurately measuring depth in through bit logging

A well logging and depth technology, applied in the directions of measurement, earthwork drilling, borehole/well components, etc., can solve problems such as complex procedures, low measurement efficiency and accuracy, and many depth measurement parameters, so as to achieve high measurement efficiency and excellent results. Accurate, easy-to-operate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

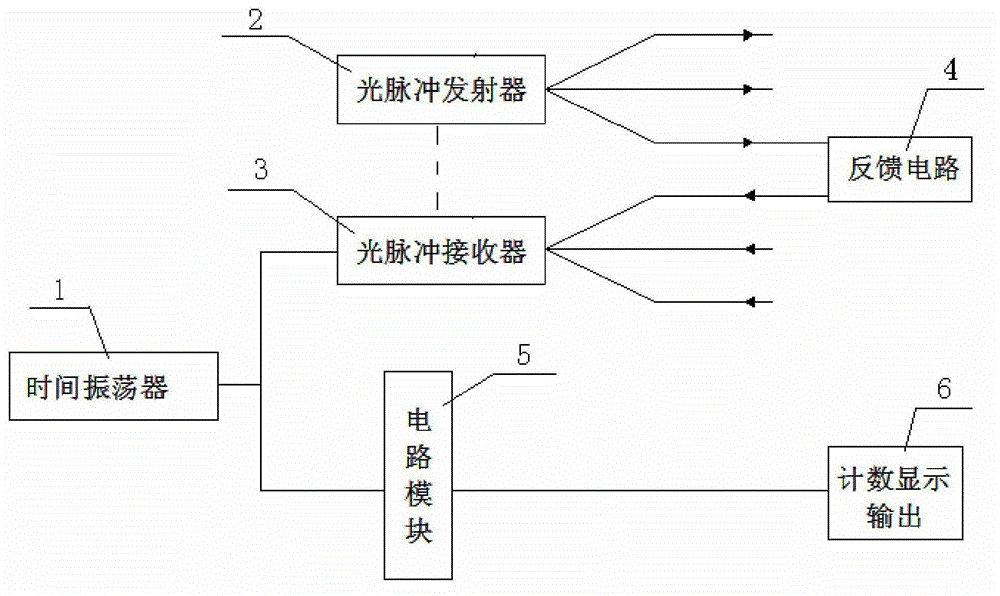

[0015] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0016] The method of accurately measuring the depth in well logging through the drill bit. During logging operations, the actions of lowering the drill pipe are: the elevator puts the drill pipe, lifts the drill pipe and pulls it to the wellhead drill pipe, makes up the hydraulic tongs, and lowers the drill pipe. Rod, put slips, release elevator and finally lift elevator, install speed sensor on hydraulic tongs and elevator to monitor the vibration of the two tools, when the vibration changes suddenly, the elevator will hold the drill pipe and buckle up , start to calculate the hook displacement after the hydraulic tongs are buckled up, until the elevator is released, this distance is the depth of going down the well.

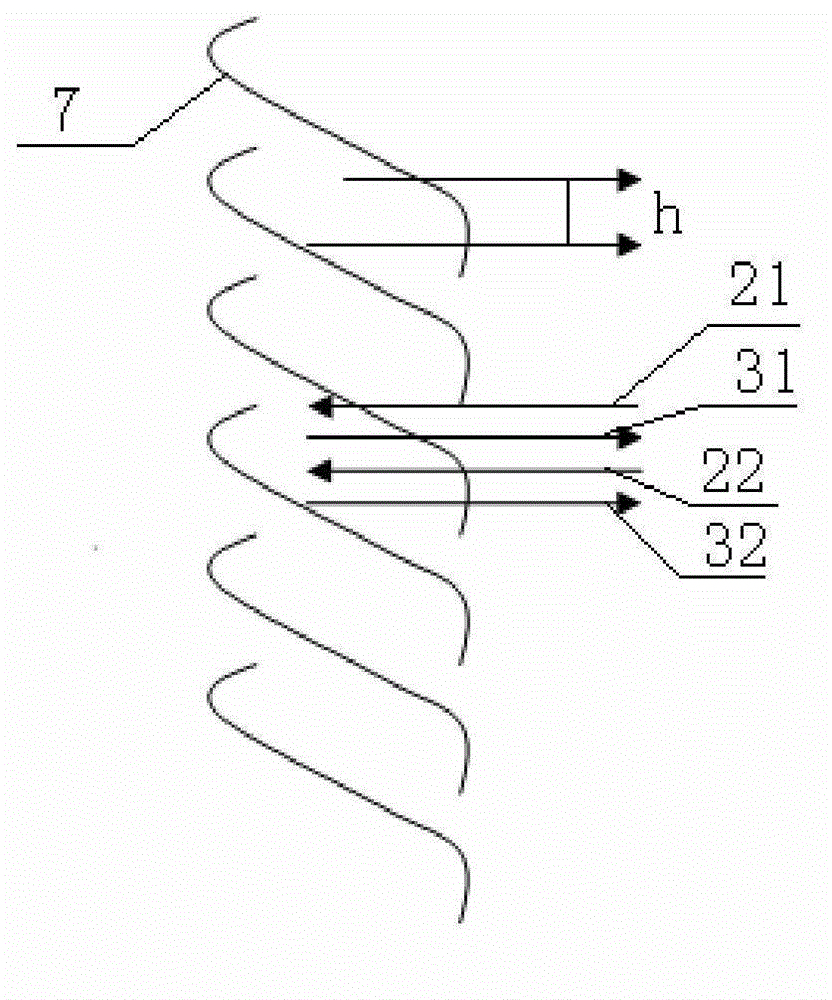

[0017] like figure 1 , figure 2 As shown, h is the gap between the two small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com