Insulating bearing with insulating ferrule and manufacturing method thereof

A technology of insulating bearings and insulating sleeves, which is applied in the direction of rotating bearings, bearings, bearing components, etc., can solve the problems of cumbersome and complicated manufacturing processes, hidden dangers of insulation reliability, and high manufacturing costs, so as to reduce costs, improve insulation levels and insulation Effects of Reliability and Manufacturing Cost Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] One-piece mechanism or injection molding to make the insulating outer ring.

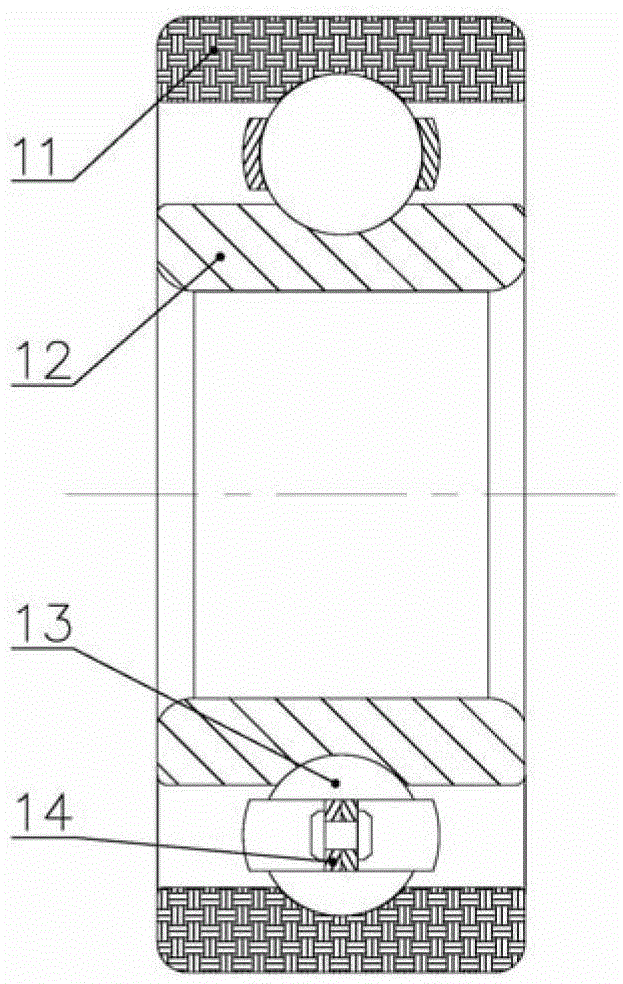

[0071] as attached figure 1 , an insulating bearing with an insulating outer ring made of insulating materials as a whole, including an outer ring 11, an inner ring 12, balls 13 and a retainer 14, wherein the outer ring 11 is made of ceramic materials, and ceramic tubes, rings or rods are selected. The insulating outer ring 11 is made by mechanical processing, and then assembled with the inner ring 12 and balls 13 made of bearing steel to form an insulating bearing.

[0072] In this embodiment, when the insulating material is resin or plastic, the insulating outer ring can also be made by precision injection molding.

Embodiment 2

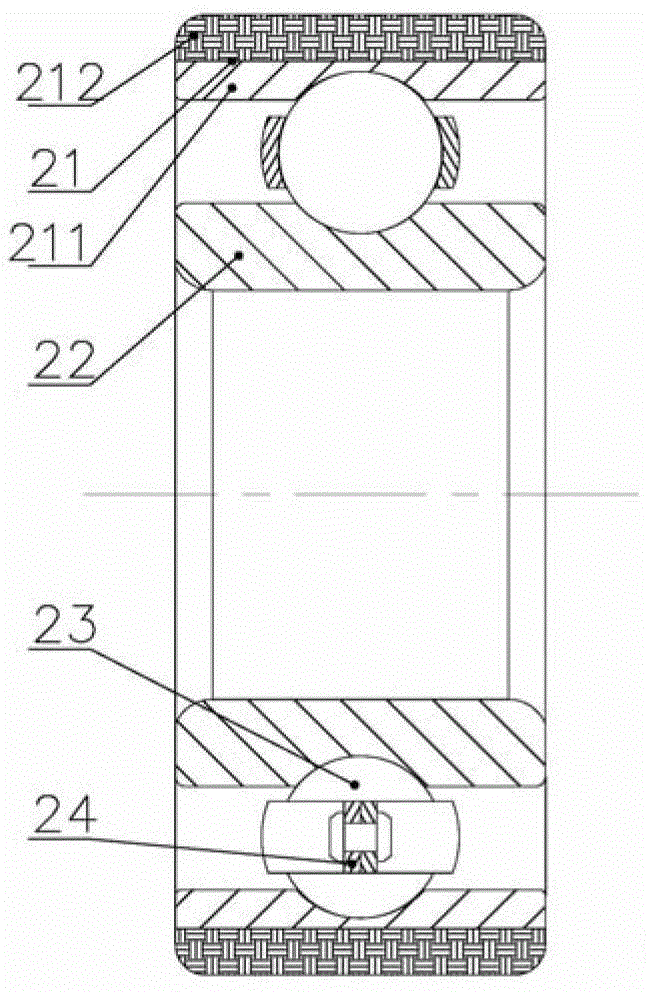

[0074] The insulating outer ring is made by split mechanism or injection molding. The insulating outer ring is composed of an insulating ring sleeve and a steel ring sleeve with an outer raceway.

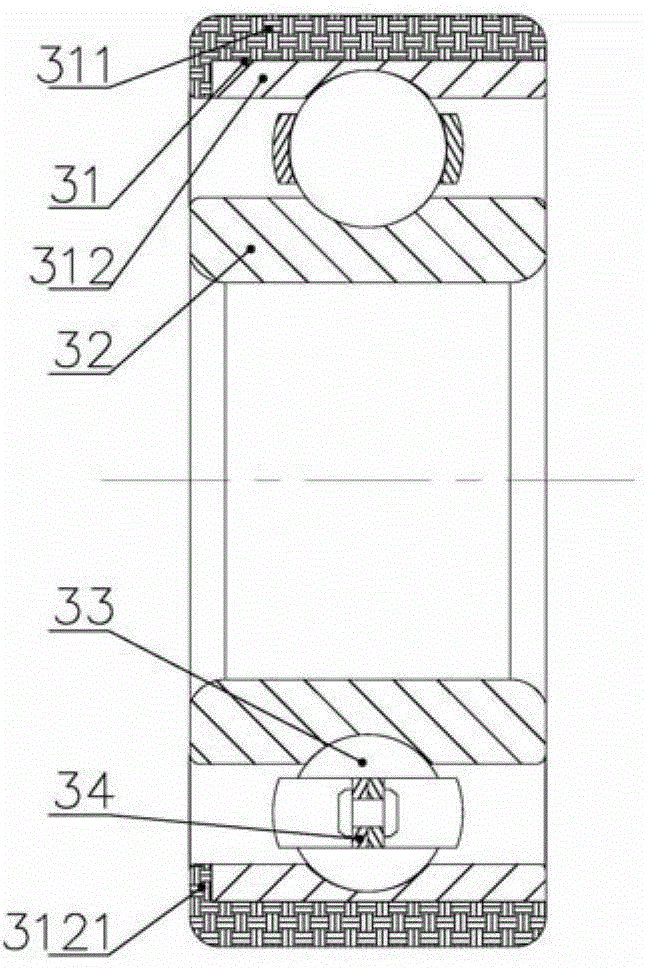

[0075] The insulating ring sleeve and the steel ring sleeve with outer raceway are press-fitted into one body. The shape of the insulating ring sleeve in this embodiment is selected as one end with an inward edge 3121 , as attached image 3 .

[0076] as attached image 3 , the half body is made of insulating material to insulate the insulating bearing of the outer ring, including the outer ring 31, the inner ring 32, the ball 33 and the cage 34, wherein the outer ring 31 is passed by the bearing steel ring sleeve 311 with the outer raceway. Press in a ceramic insulating ring sleeve 312 with an inward edge at one end to make an insulating outer ring.

[0077] The manufacturing process of bearing steel ring sleeve 311 with outer raceway is the same as that of normal bearing steel ...

Embodiment 3

[0088] The insulating outer ring is made by separate injection molding. The insulating outer ring is composed of an insulating ring sleeve and a steel ring sleeve with an outer raceway.

[0089] The insulating ring sleeve and the steel ring sleeve with outer raceway are injection-molded as a whole. Image 6 , The insulating ring sleeve of this structure adopts injection molding.

[0090] as attached Image 6 , the insulating bearing of the insulating outer ring made of phenolic resin, including the outer ring 61, the inner ring 62, the ball 63 and the retainer 64, wherein the outer ring 61 is pre-molded by the bearing steel ring sleeve 611 with the outer raceway through the injection mold Embedding injection molding to make the insulating outer ring. After injection molding, phenolic resin forms an insulating ring sleeve 612 with inward edges 6121 at both ends. The insulating ring sleeve 612 and the bearing steel ring sleeve 611 form a tight fit relationship in the radial di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com