Composite double-lip oil seal

A lip oil and outer oil seal technology, which is applied in the field of double-lip structure oil seals, can solve the problems of poor sealing performance, unsatisfactory, short life, etc., achieve long service life, enhance the effect of sealing performance, and solve the effects of sealing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

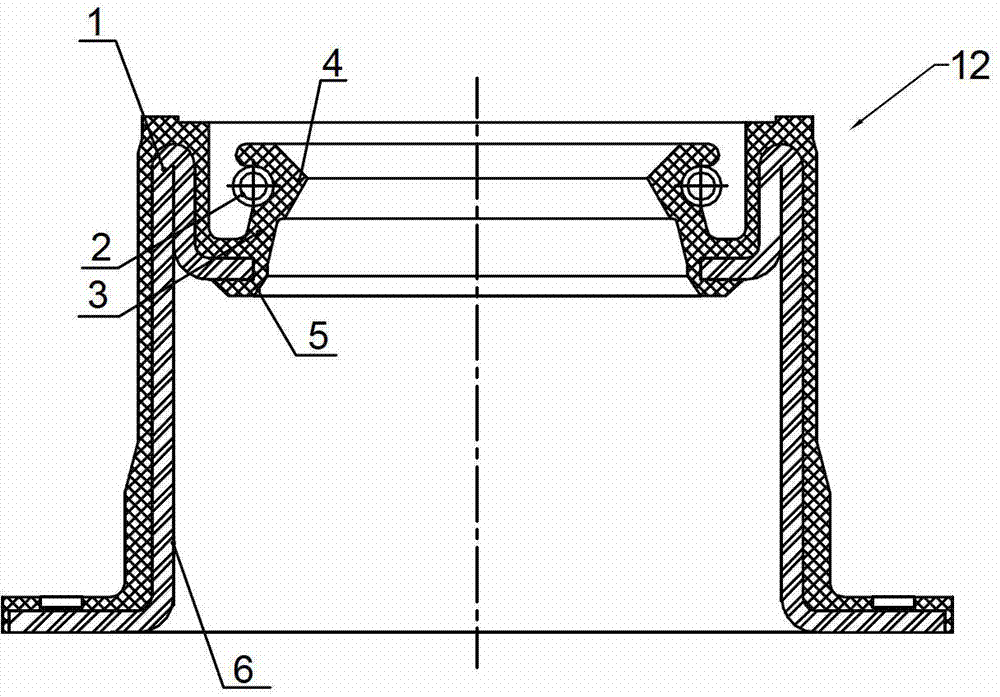

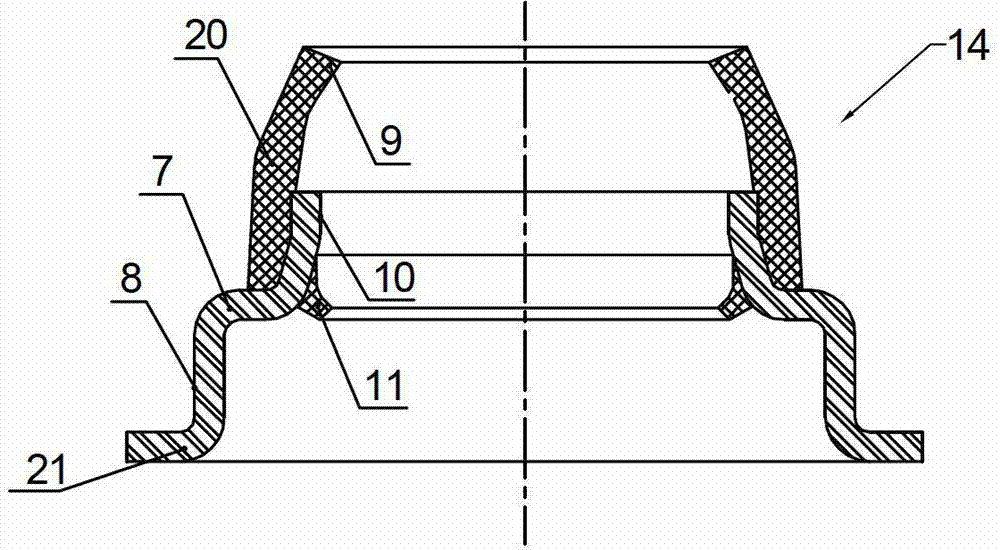

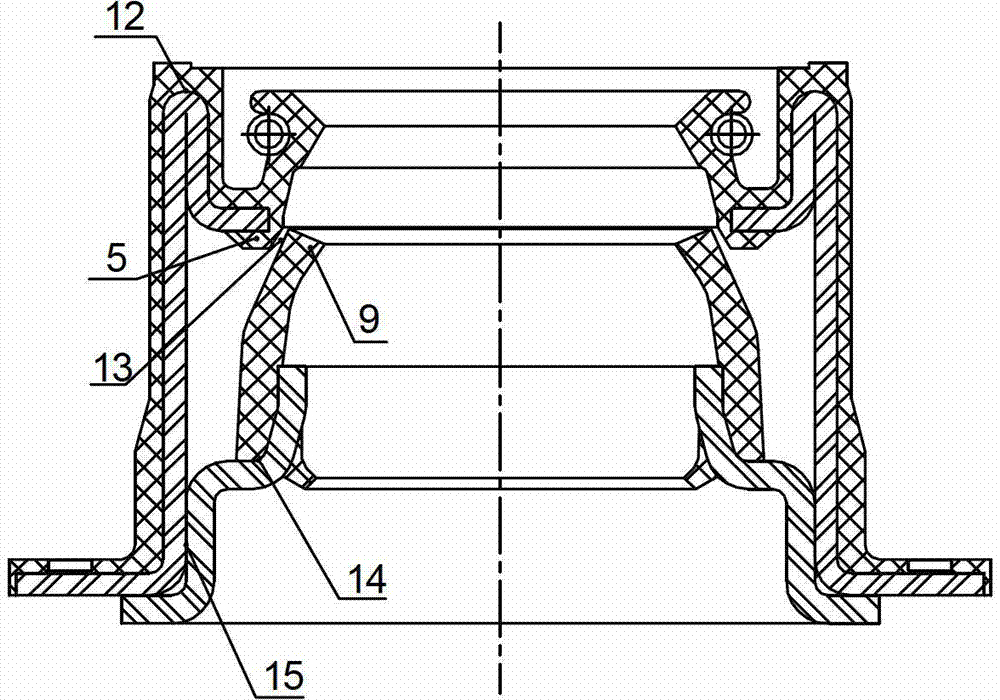

[0012] refer to Figure 1-Figure 3 , a composite double-lip oil seal, which is composed of an outer oil seal structure 12 and an inner oil seal structure 14, wherein the outer oil seal structure 12 is formed by vulcanizing the outer metal skeleton 1 and the outer oil seal structure rubber body 3 through a mold. After molding, the outer oil seal structure The rubber body 3 forms the spring lip 4 and the bevel boss 5, and the middle and lower part of the inner side of the outer oil seal structure 12 exposes the metal skeleton, and the exposed metal skeleton serves as the inner mating surface 6 and fits with the inner oil seal structure 14; the inner oil seal structure 14 is formed by the inner metal The skeleton 7 and the rubber body 20 of the inner oil seal structure are molded by vulcanization. After molding, the rubber body 20 of the inner oil seal structure forms a springless lip 9 and an auxiliary lip structure 11. The surface 8 is fitted with the inner mating surface 6 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com