Installation structure convenient for disassembling and assembling expansion joint of heat transfer casing

An installation structure and technology of expansion joints, which are applied to expansion compensation devices for pipelines and protect pipelines and pipes through thermal insulation, can solve the problems of difficulty in installation and disassembly of expansion joints, solve inconvenient installation and disassembly, reduce heat Stress and force, loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

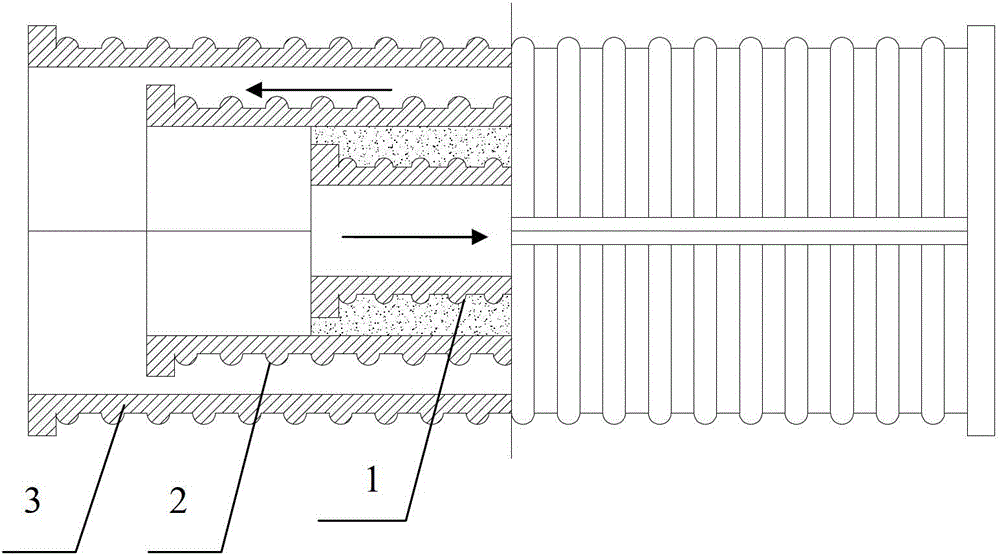

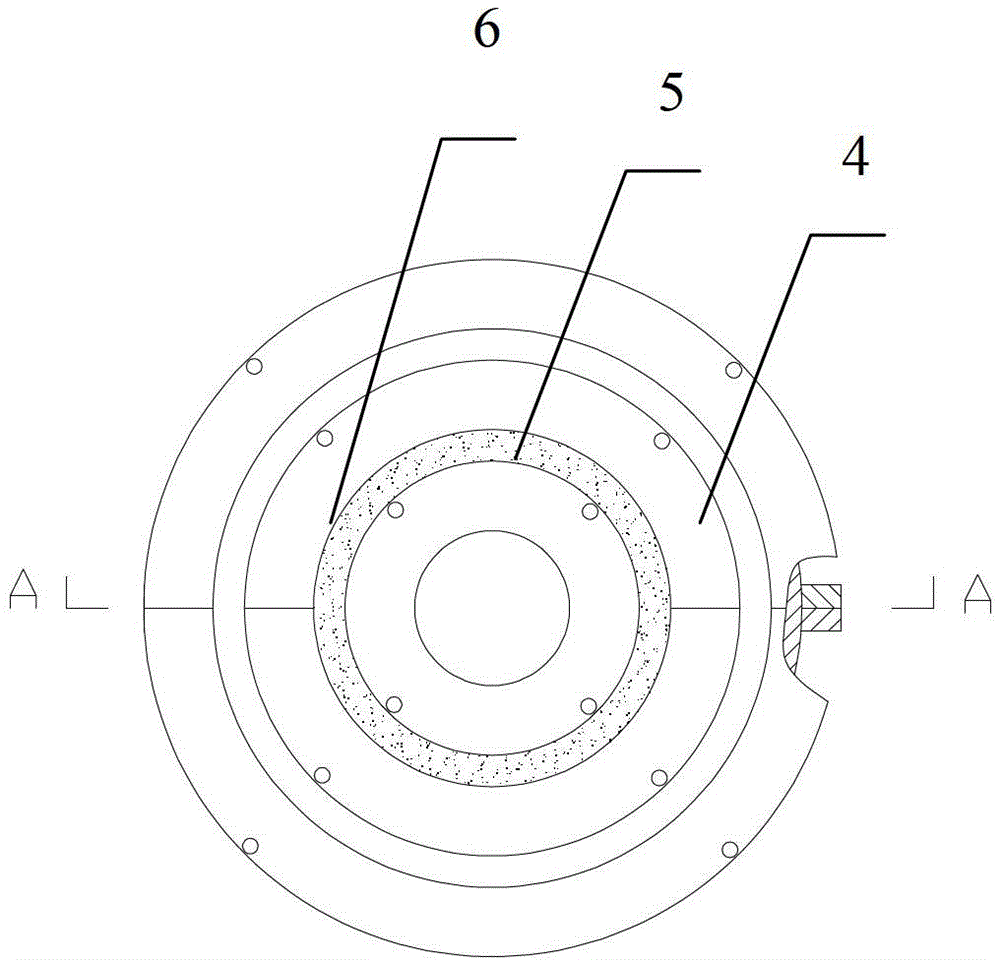

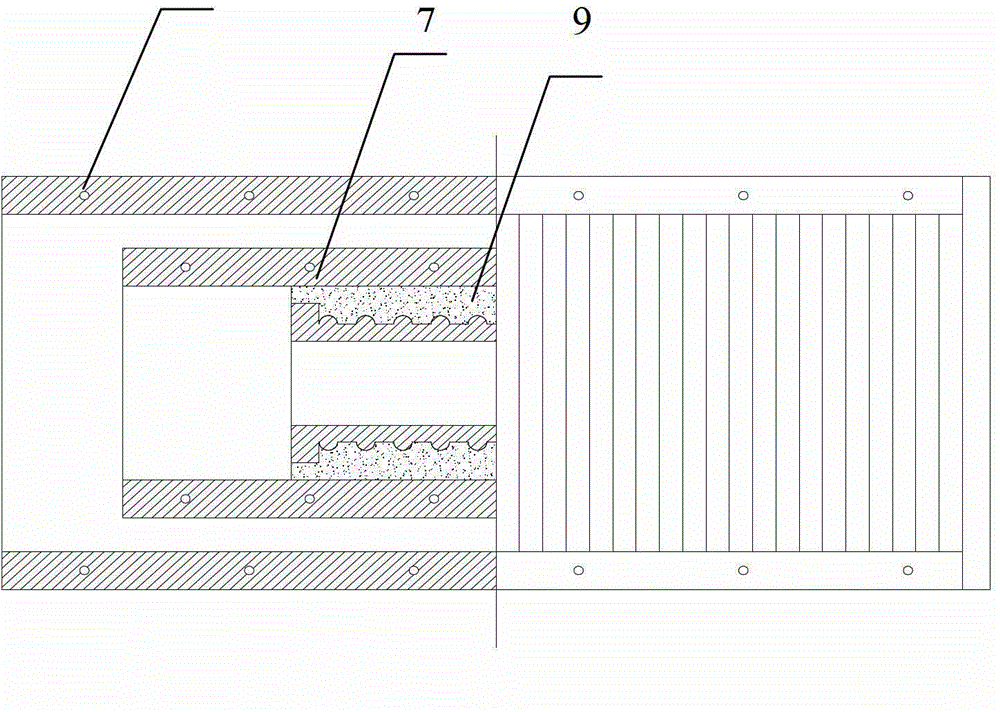

[0019] Such as figure 1 , figure 2 and image 3 As shown, the present invention is an installation structure that facilitates the disassembly and assembly of the thermowell expansion joint. There is an expansion joint inner tube 1 with a smaller diameter in the expansion joint outer tube 3 with a larger diameter, and an expansion joint inner tube 1 outside the expansion joint. The thermal insulation cotton layer 9, the thermal insulation cotton layer 9 coats the expansion joint intermediate pipe 2, in order to absorb the thermal expansion of the inner and outer expansion joints, there is a gap between the expansion joint inner pipe 1 and the expansion joint intermediate pipe 2. The hot fluid conveyed by the inner pipe of the heat transfer pipe system flows in the inner pipe 1 of the expansion joint, and the cold fluid returned by the heat transfer pipe system flows in the annular space between the middle pipe 2 of the expansion joint and the outer pipe 3 of the expansion joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com