Light emitting diode (LED) lamp with convection channel penetrating through light source baseplate

A technology of LED lamps and light source substrates, applied in the field of LED lamps, can solve the problems that the central part of the radiator cannot form air convection and the temperature of the central part of the light source is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

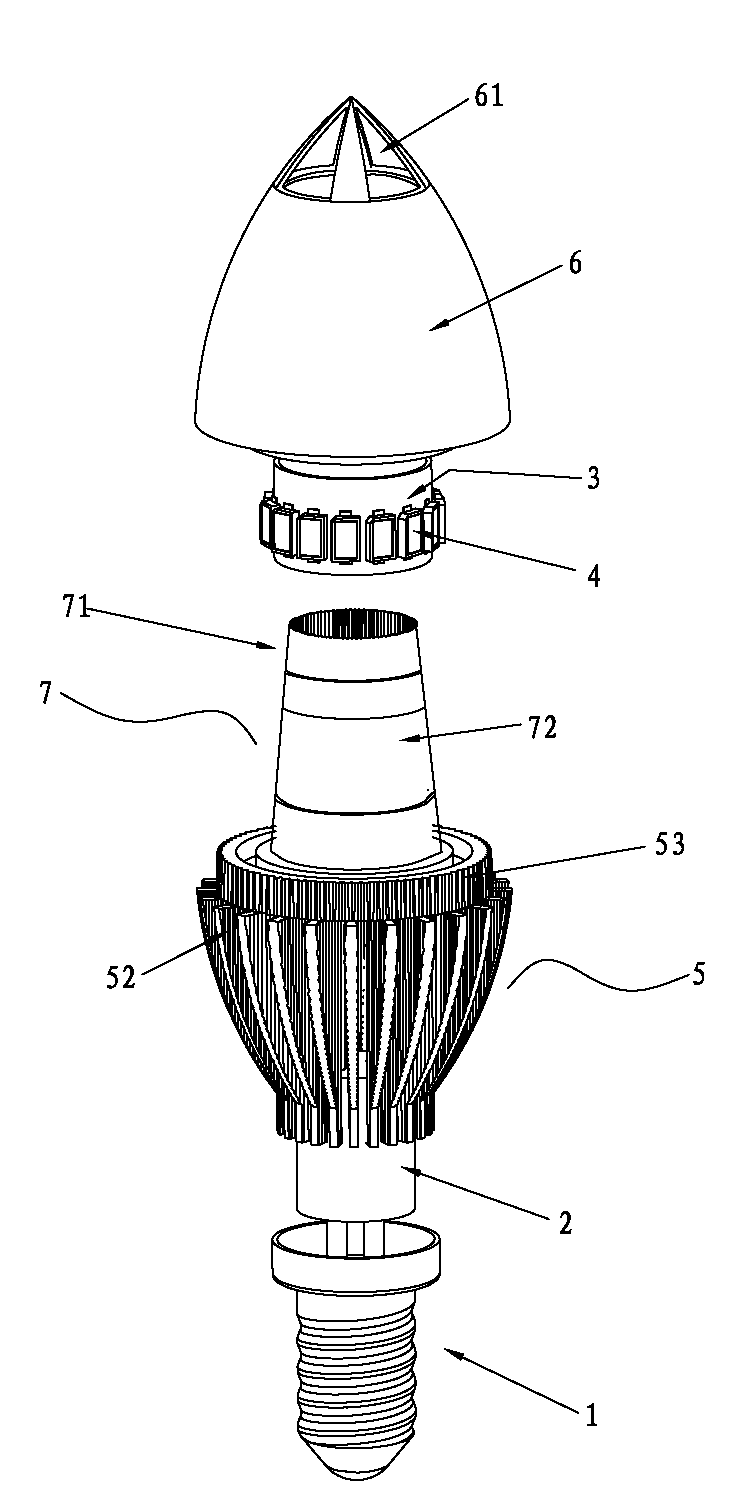

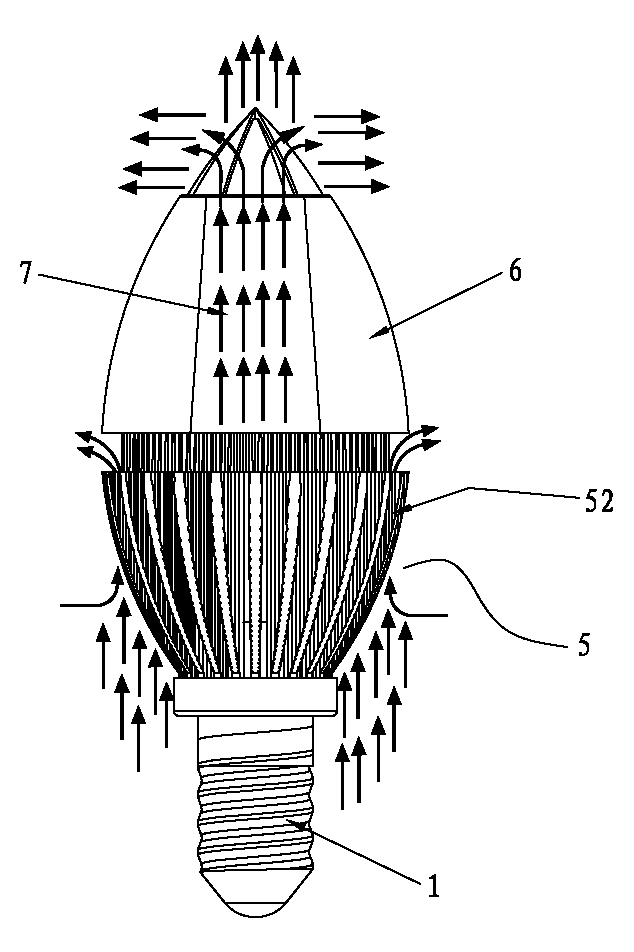

[0020] Such as figure 1 , figure 2 , image 3 As shown, an LED lamp with a convection channel passing through the light source substrate includes a lamp holder 1, an LED driver 2, an LED substrate 3, an LED light source 4, a finned radiator 5 and a lampshade 6 and is fixedly connected. The LED light source 4 is arranged on On the LED substrate 3 , the LED lamp head is connected to one end of the finned radiator 5 , and the lampshade 6 is connected to the other end of the finned radiator 5 . The LED driver 2 is arranged on one end of the finned heat sink 5 with the LED lamp cap 1 and is electrically connected with the LED lamp cap 1; The guide tube 7 extends into the lampshade 6, and there is a gap between two adjacent cooling fins 52 of the finned radiator 5, which communicates with the inner cavity 51 of the finned radiator 5;

[0021] The top of the lampshade 6 has a guide hole 61 , and the guide hole 61 is opposite to the suspended end of the heat dissipation guide pipe...

Embodiment 2

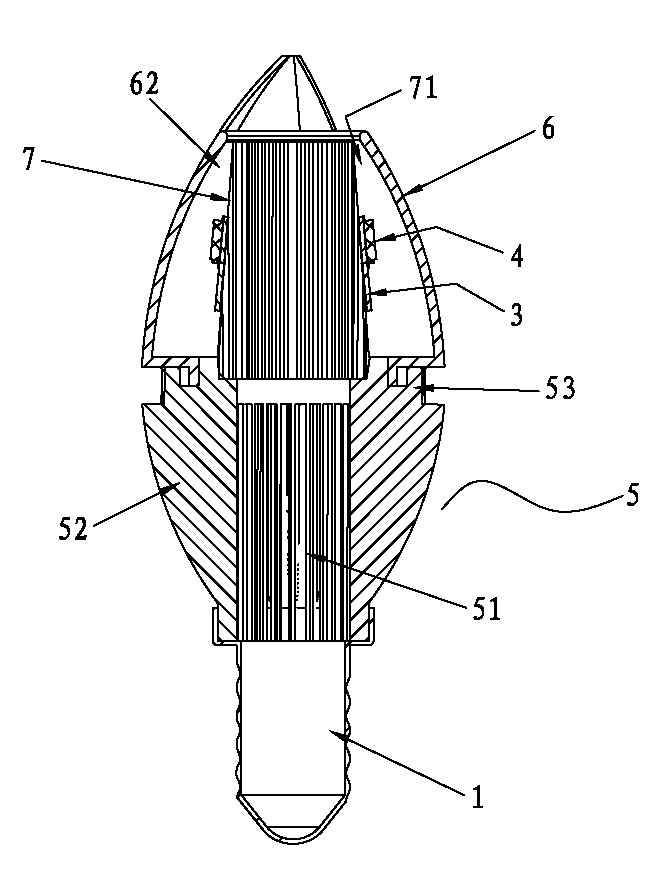

[0028] Such as Figure 4 , Figure 5 , Figure 6 As shown, the LED substrate 3 is in the shape of a circular disc, the heat dissipation duct 7 passes through the LED substrate 3 , and the LED substrate 3 is bonded to the annular seat 53 of the finned heat sink 5 . The LED substrate 3 cooperates with the end of the central tube 51 at the connecting end of the finned heat sink 5 and the lampshade 6 .

[0029] Figure 5 It is the front view of the present invention when it is hoisted. Cold air passes through the inner cavity of the guide hole 61 on the lampshade, the heat dissipation guide tube 7, and the finned radiator 5, and dissipates heat rapidly through the gap between two adjacent fins.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com