Rotary type terminal seat and terminal push-pull force detecting device thereof

A detection device and terminal block technology, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problems of inability to meet mass production, inaccuracy, low automation intensity, etc., and reduce labor intensity , Improve the degree of automation, reduce the effect of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

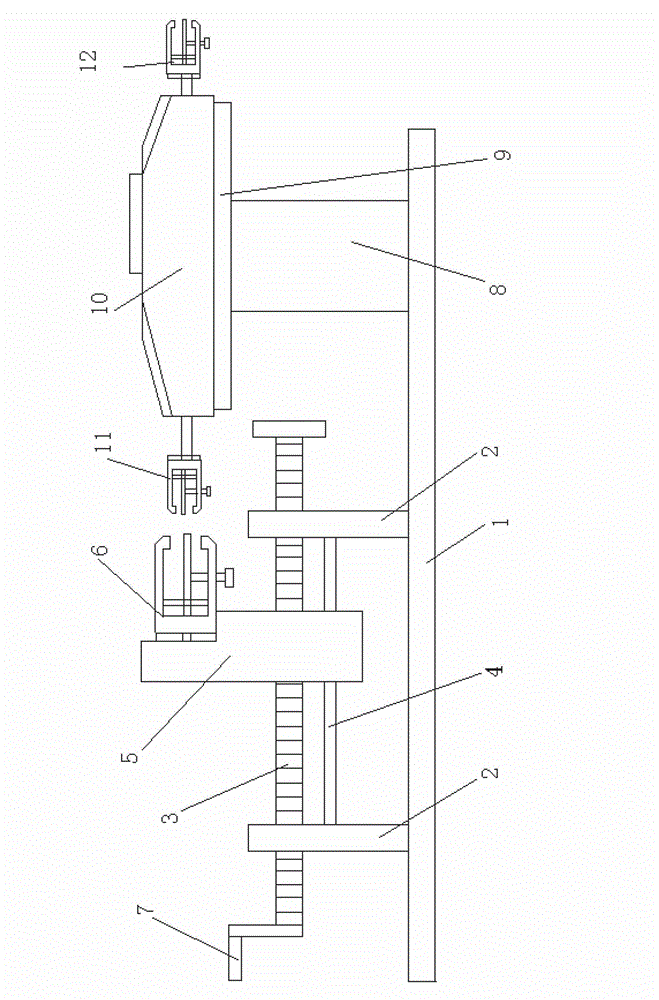

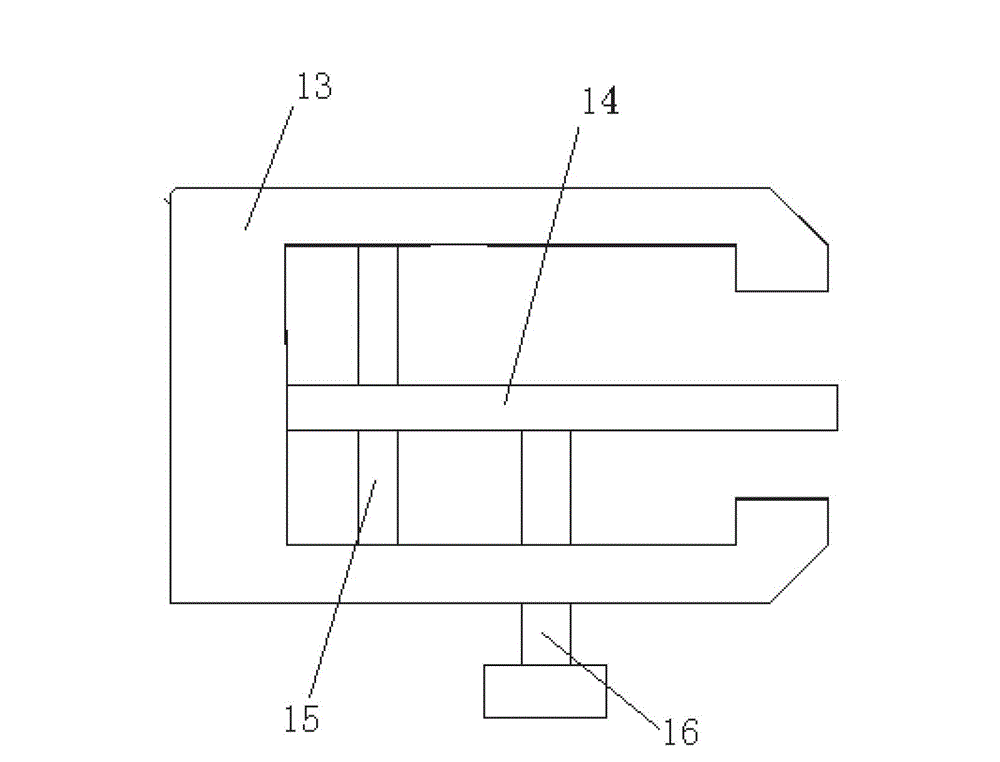

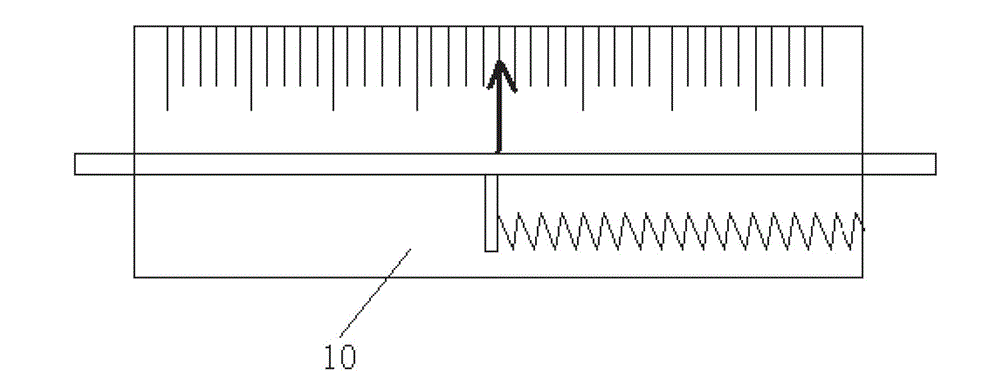

[0016] Referring to the accompanying drawings, a rotary terminal base and its terminal push-pull force detection device includes a base 1, a left support 2 is provided at one end of the base 1, and a horizontal screw 3 and a guide rod 4 are mounted on the left support 2. A guide sleeve 5 is installed on the screw rod 3 and the guide rod 4 in cooperation. The upper end of the guide sleeve 5 is equipped with a terminal holder chuck 6. The rotation of the screw rod 3 is driven by the handle 7 at its end. The right support 8 corresponding to the support 2, the right support 8 is rotatably installed with a push-pull force meter fixing base 9, the push-pull meter fixing base 9 is fixedly mounted with a push-pull force meter 10, the push rod and the pull rod of the push-pull force meter 10 Terminal chucks 11 and 12 are respectively installed at the ends; the structure of the terminal holder chucks 6 and the terminal chucks 11, 12 are the same, and each includes a holder 13 with a U-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com