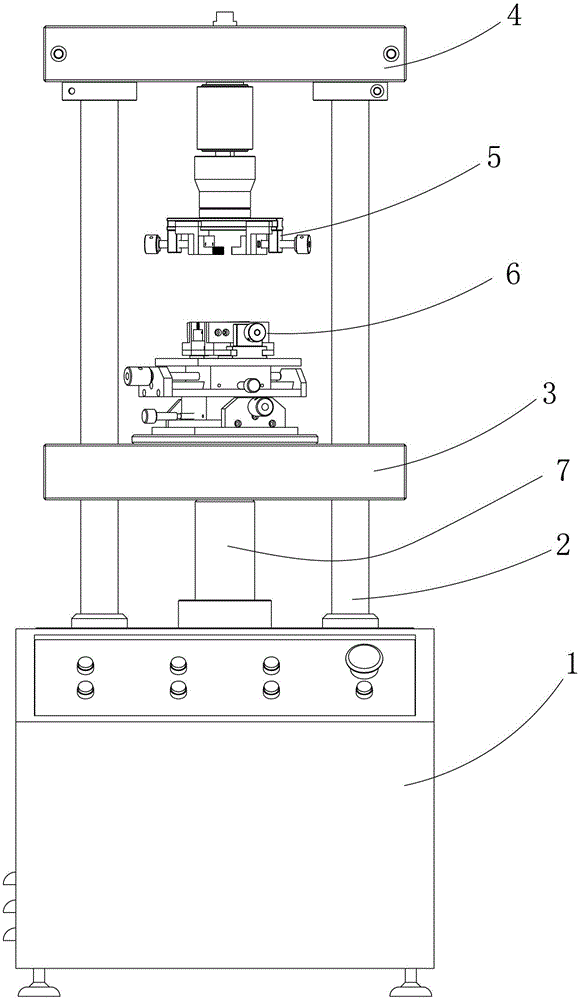

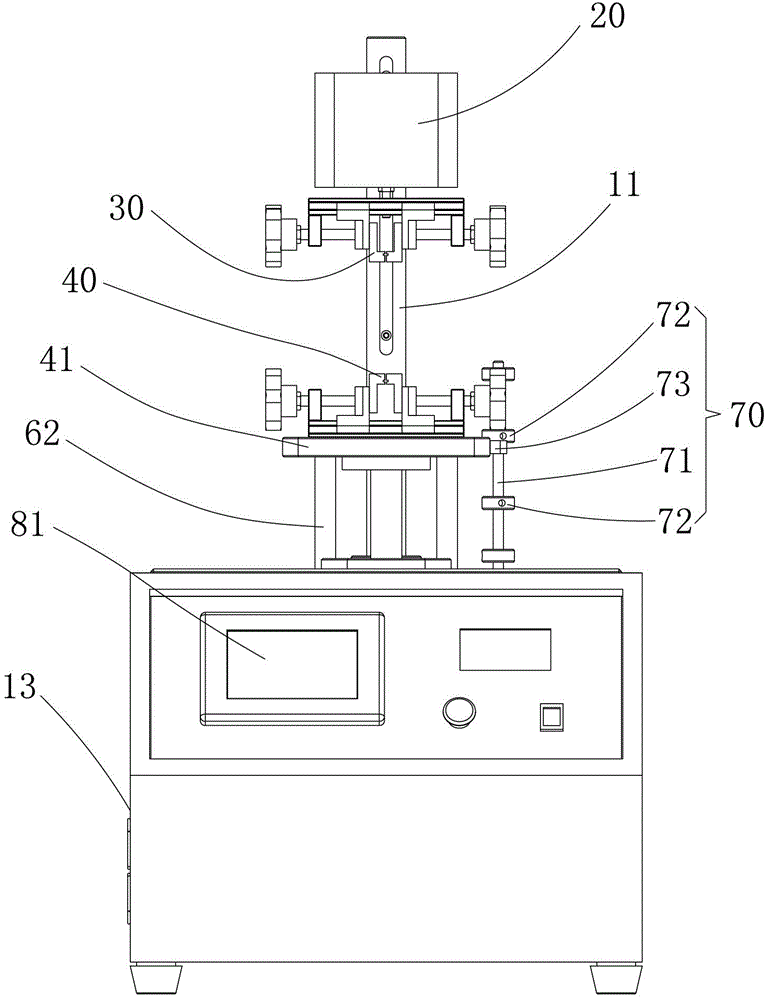

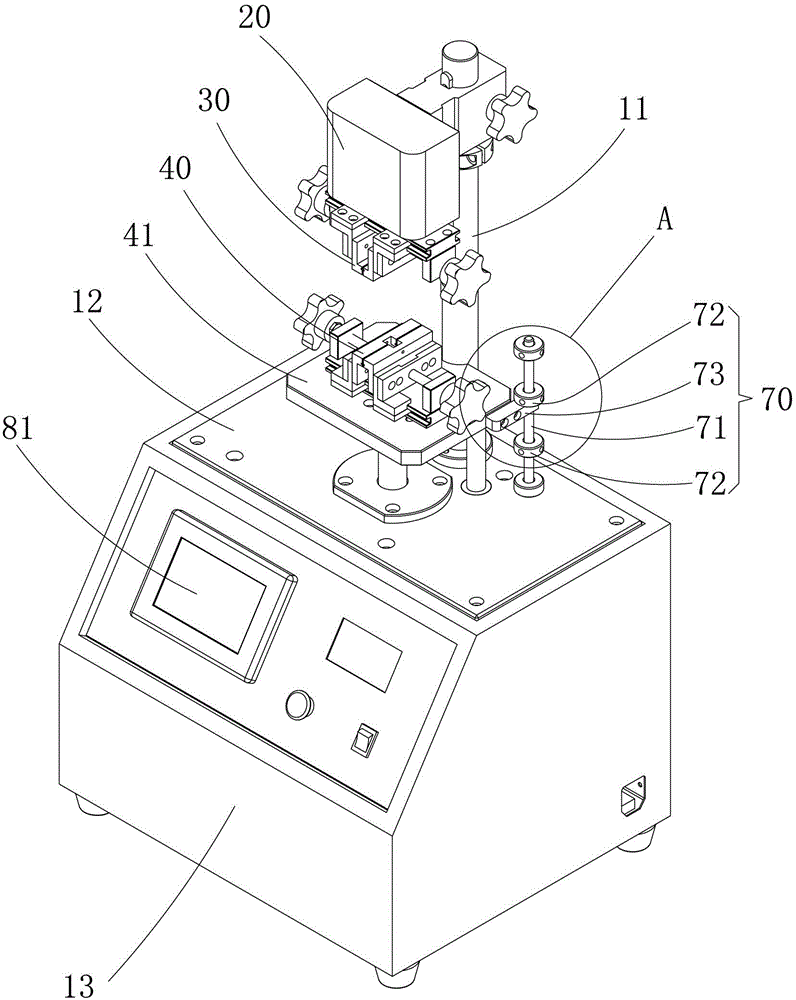

Insertion and extraction force testing device

A test device and plug-in force technology, applied in the field of testing, can solve the problems of high cost of use, high requirements for operators, high price, etc., to achieve the effect of ensuring work stability, reducing cost of use, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0036] The transmission mechanism 54 includes a drive wheel 541 coaxially fixedly connected with the output shaft of the motor 53, a driven wheel 542 coaxially fixedly connected with the nut 52, and a drive wheel 542 wound around the drive wheel. 541 and the transmission belt 543 on the driven wheel 542. In the embodiment of the present invention, the transmission mechanism 54 is preferably configured as a synchronous pulley transmission mechanism with precise and stable transmission and high transmission efficiency, that is, the driving pulley 541 and the driven pulley 542 are respectively configured as a driving pulley and a driven pulley, The transmission belt 543 is a synchronous belt. As an embodiment, the transmission mechanism 54 can also be set as a pulley transmission mechanism, that is, the driving pulley 541 and the driven pulley 542 are respectively a driving pulley and a driven pulley, and the transmission belt 543 is a transmission belt; or It can also be set as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com