Classification detection system and method of ingot surface defect

A defect classification and ingot surface technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of time-consuming and labor-intensive detection and recognition, low recognition accuracy, low detection efficiency, etc., to achieve convenient query processing, high detection accuracy, and running speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

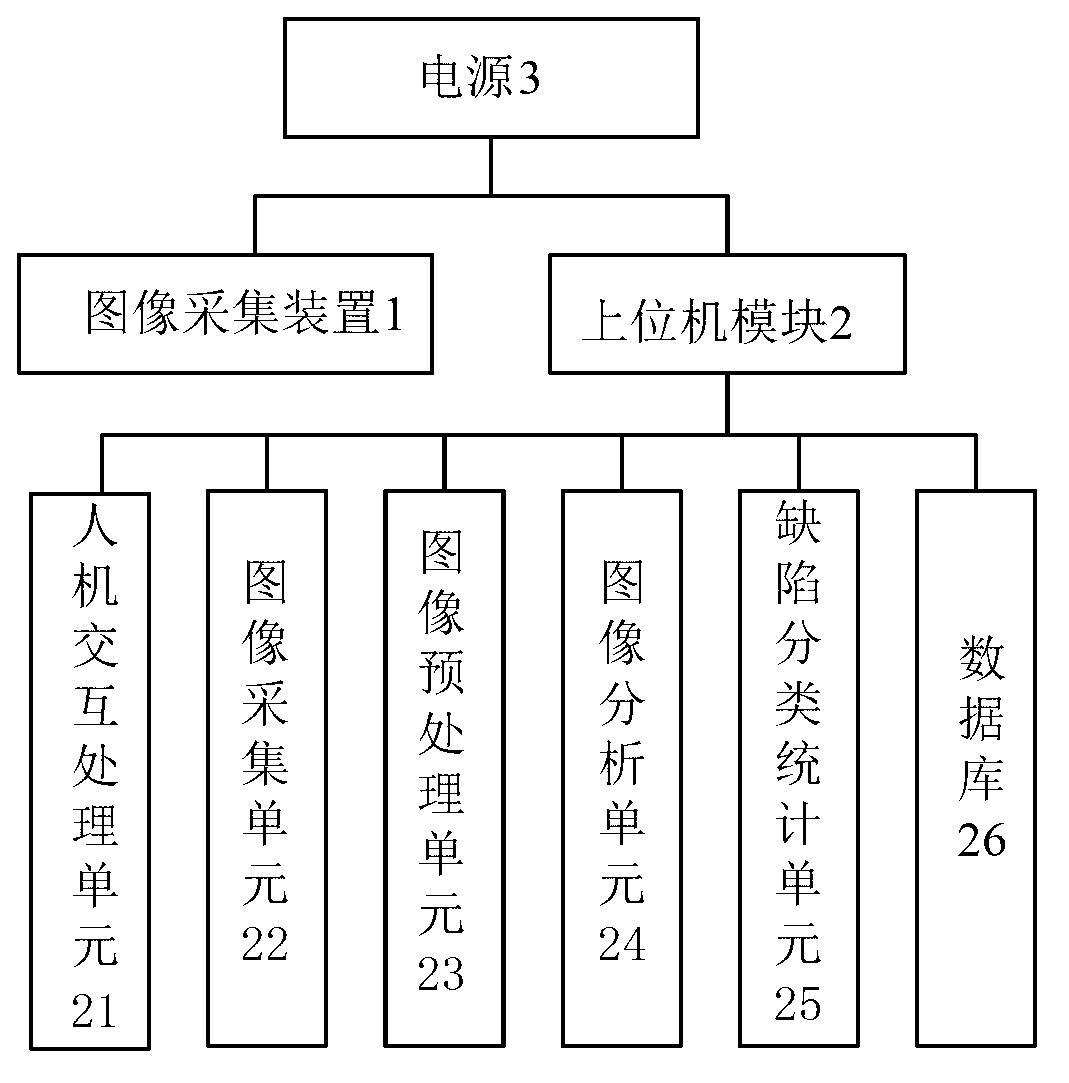

[0026] see figure 1 , a steel ingot surface defect classification detection system, including: an image acquisition device 1, a host computer module 2 and a power supply 3, the image acquisition device 1 adopts a CCD color camera, which is connected with the host computer module 2, and is used for real-time acquisition of steel ingots on the assembly line Image; the upper computer module 2 is used to process and analyze the collected images, and extract the defect area; the power supply is respectively connected to the image acquisition device 1 and the upper computer module 2 to provide power; wherein, the upper computer module 2 further includes:

[0027] Human-computer interaction processing unit 21: used to accept user operations, realize initialization work and parameter setting, and display detection information and detection results in real time.

[0028] Par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com