Multi-level confocal conic surface secondary reflection unit light convergence method

A technology of secondary reflection and conic surface, applied in optics, condensers, optical components, etc., can solve the problems of unsuitable light convergence, small convergence ratio, and difficult to obtain converged light, etc., to achieve outstanding convergence effect, small divergence, easy to use Effects of use and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

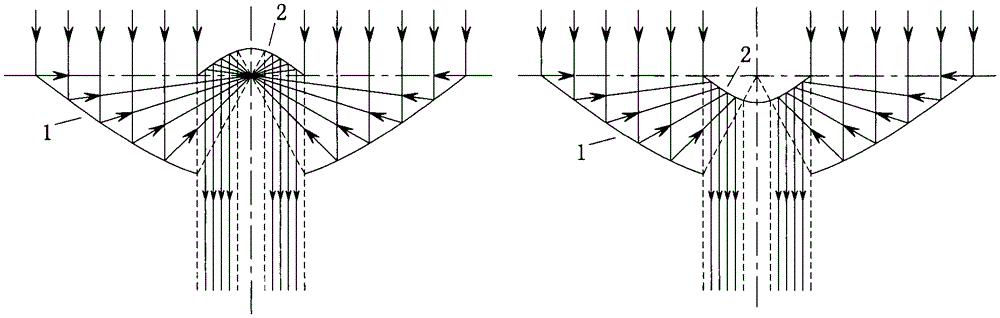

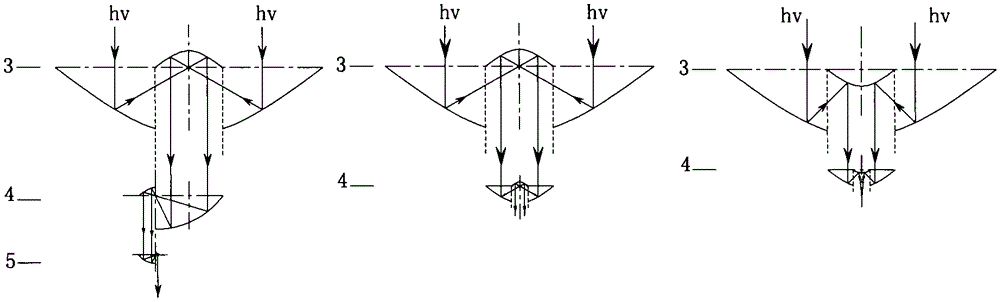

[0023] This embodiment is a two-level direct aggregation system, please refer to the attached image 3 In the right figure in the figure, the secondary reflective unit of the conical surface in the primary concentrating layer 3 is a confocal combination of parabola ~ parabola with the same opening direction, and the placement position of the secondary reflective unit in the secondary concentrating layer 4 utilizes The spatial shadow area of the first-level parallel converging light, and adopts the attached figure 2 A secondary reflection element that produces intersecting converging rays is shown in . The entire converging system is installed in direct series with the first-level light-gathering layer 3 and the second-level light-gathering layer 4 .

[0024] In this embodiment, its action process is as follows: parallel light rays (low luminance light rays or low-density light energy) enter the secondary reflection unit of the first-level light-gathering layer 3, and are c...

Embodiment 2

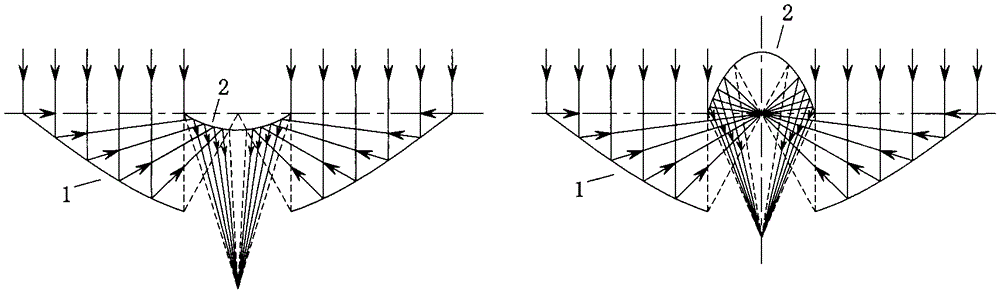

[0026] This embodiment is a converging system that contains a multi-level concentrating layer and a plane reflective layer connected in tree form, please refer to the attached Figure 4 . This example includes three levels of light concentrating layers and two levels of planar reflection layers. The confocal conical surface secondary reflection unit in the first level of light concentrating layer 3 contains a parabola-parabola confocal combination of "opening directions are consistent and opposite". The first-level plane reflection layer 6 is composed of plane mirrors 7. The location of the secondary reflection unit in the second-level light-gathering layer 4 utilizes the spatial shadow area of the light reflected by the first-level plane reflection layer 6. The second-level light-gathering layer 4 and the third-level light-gathering layer The secondary reflection units in layer 5 are all parabolic to parabola confocal combinations with “opposite opening directions”, and the...

Embodiment 3

[0029] This embodiment is a converging system that contains multi-level light concentrating layers, plane reflective layers, and light reflection channels connected in series. Please refer to the attached Figure 7 . This example contains three levels of light-gathering layers, two-level planar reflection layers, and one-level light reflection channel, and the secondary reflection of the co-focal conic surface in the first-level light-gathering layer 3, the second-level light-gathering layer 4, and the third-level light-gathering layer 5 The units are all parabolic to parabolic confocal combinations with "opposite opening directions". The primary plane reflection layer or light reflection channel layer 6 is composed of a plane mirror 7 and a light reflection channel 8. The placement position of the secondary reflection unit in the secondary light concentrating layer 4 is The spatial shadow area of the light reflected by the first-level plane reflective layer 6 is defined, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com