Semiconductor conveying equipment and taking and placing device thereof

A technology of conveying equipment and pick-and-place device, which is used in semiconductor/solid-state device manufacturing, conveyor objects, transportation and packaging, etc., can solve the problems of reduced pick-and-place chip efficiency, easy deformation, etc., to improve pick-and-place efficiency and prolong use. Longevity, the effect of reducing mechanical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

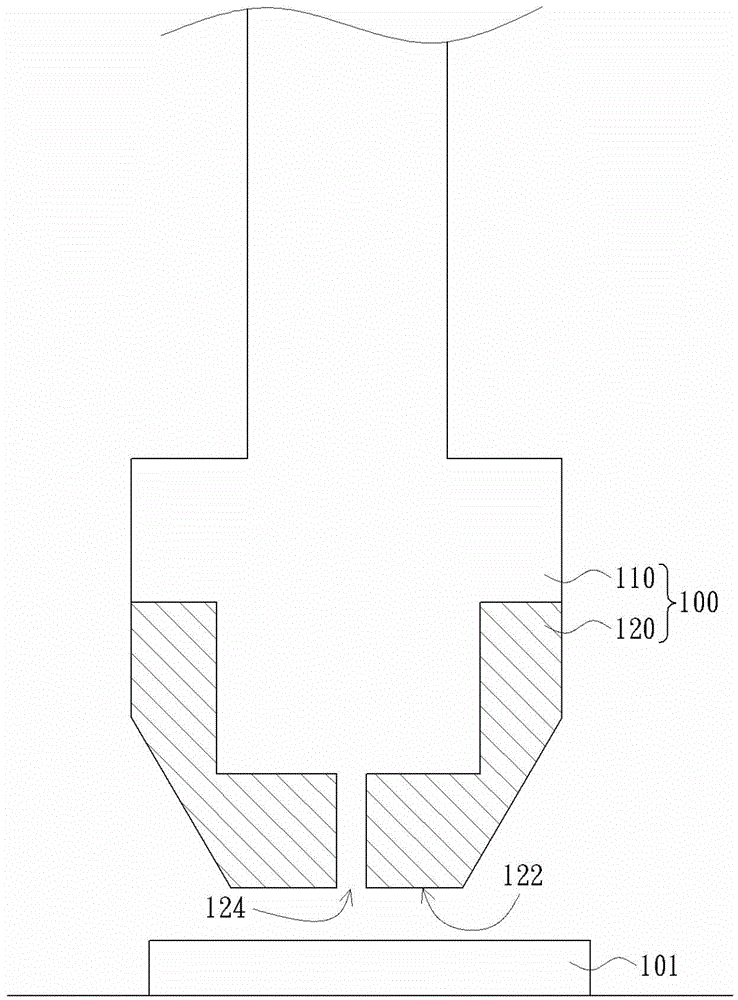

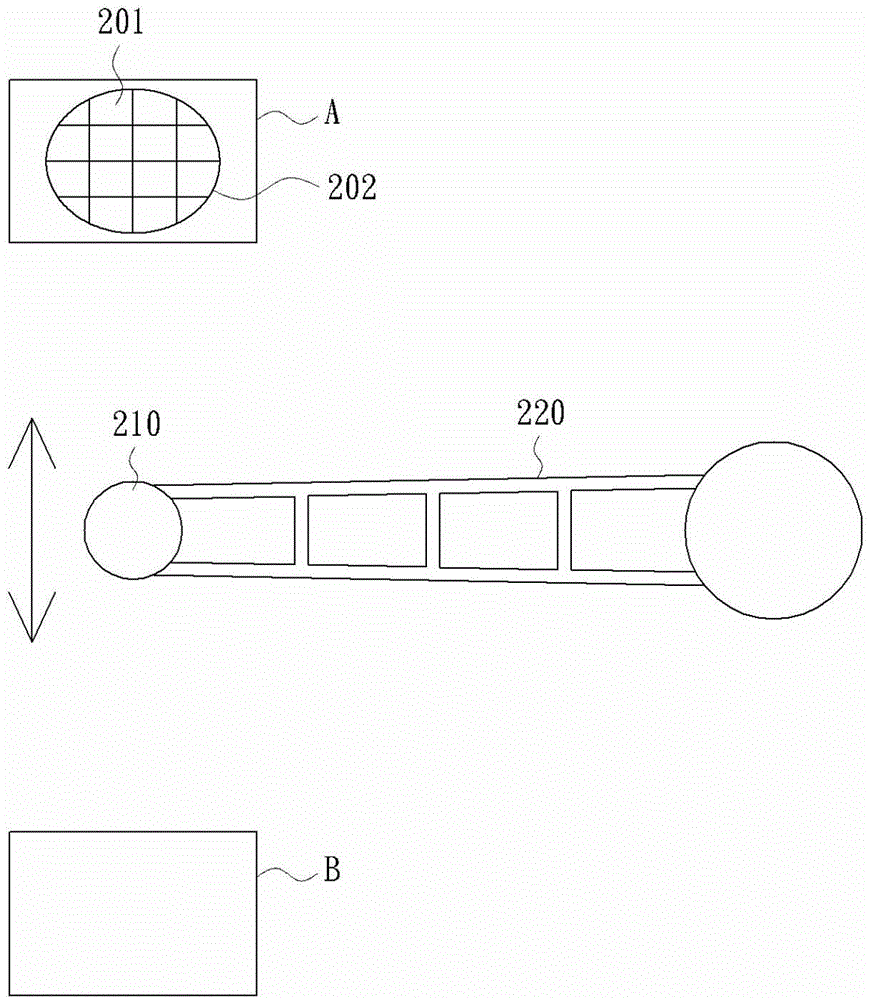

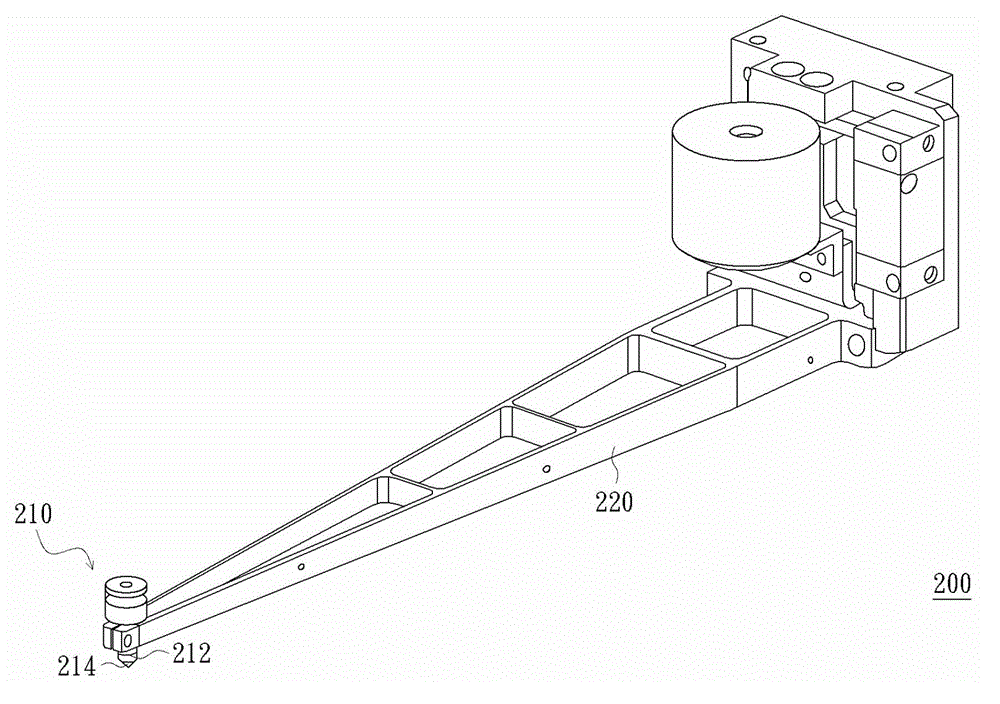

[0038] figure 2 It is a simple top view schematic diagram of semiconductor transmission equipment in an embodiment of the present invention, image 3 It is a three-dimensional schematic diagram of semiconductor transmission equipment in an embodiment of the present invention, Figure 4 Then it is a simple cross-sectional schematic diagram of the pick-and-place device in an embodiment of the present invention. Please refer to figure 2 , image 3 and Figure 4 The semiconductor transfer equipment 200 can be used to transfer the semiconductor device 201 from the temporary storage area A to the target area B. For example, the semiconductor element 201 of this embodiment is, for example, a chip, and the semiconductor transfer device 200 is, for example, a chip sorter, which is used to sort and sort the plurality of chips 201...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com