Organic light-emitting diode (OLED) device packaging method and OLED display device

A display device and device packaging technology, which is applied in the manufacture of electric solid-state devices, semiconductor devices, semiconductor/solid-state devices, etc., can solve the problems of unfavorable narrow frame realization, unfavorable glass substrate utilization rate, production efficiency, and large frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

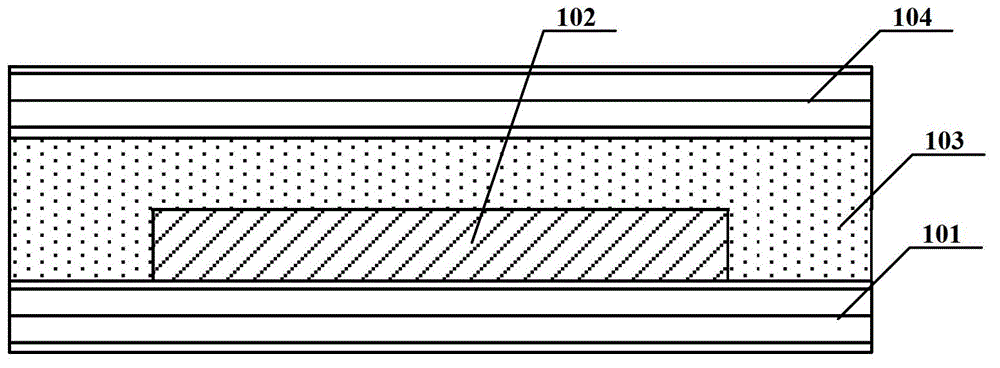

[0018] Embodiments of the present invention provide an OLED encapsulation method and an OLED display device. At least one layer of protective layer and sealant are provided outside the position of the film, thereby preventing moisture intrusion, reducing the frame outside the film during OLED encapsulation, and reducing the The difficulty of the process improves the overall production efficiency and yield.

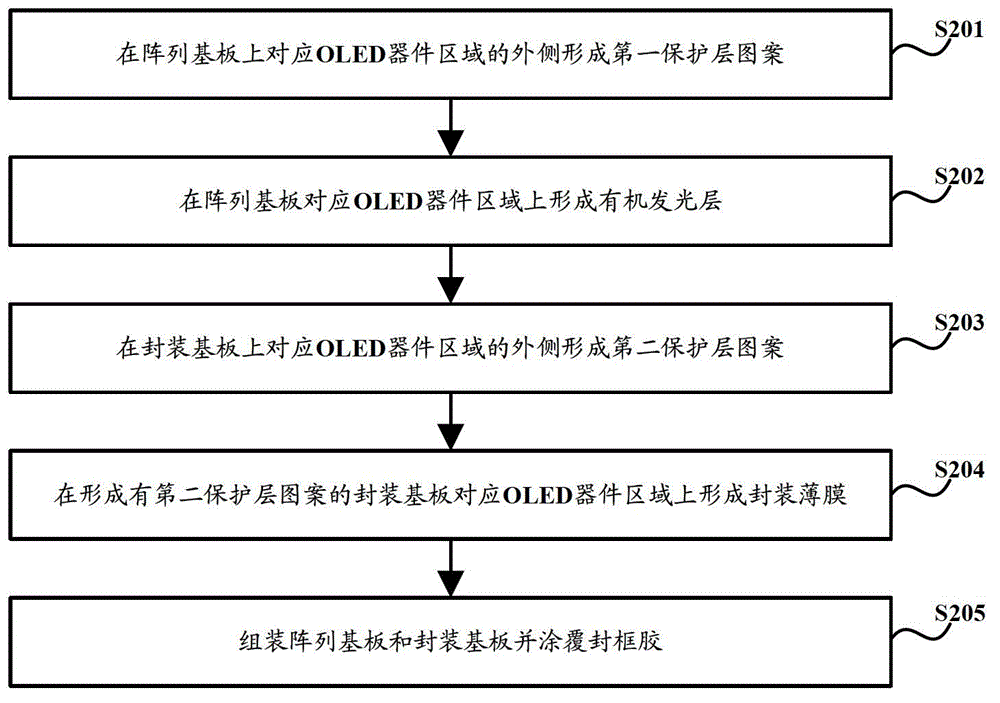

[0019] Such as figure 2 As shown, the OLED encapsulation method provided by the embodiment of the present invention includes:

[0020] Step S201, forming a first passivation layer (Passivation Layer) pattern on the outside of the corresponding OLED device area on the array substrate;

[0021] Step S202, forming an organic light-emitting layer on the region of the array substrate corresponding to the OLED device;

[0022] Step S203, forming a second protective layer pattern on the outer side of the packaging substrate corresponding to the OLED device area;

[0023] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com