Cabinet structure

A cabinet and frame technology, which is applied in the frame structure field of cabinets, can solve the problems of shortening the service life of sealing materials, inability to adapt to the industrial environment, and relatively high precision requirements, and achieve the effect of improving the protection level, saving materials and labor, and expanding the application environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

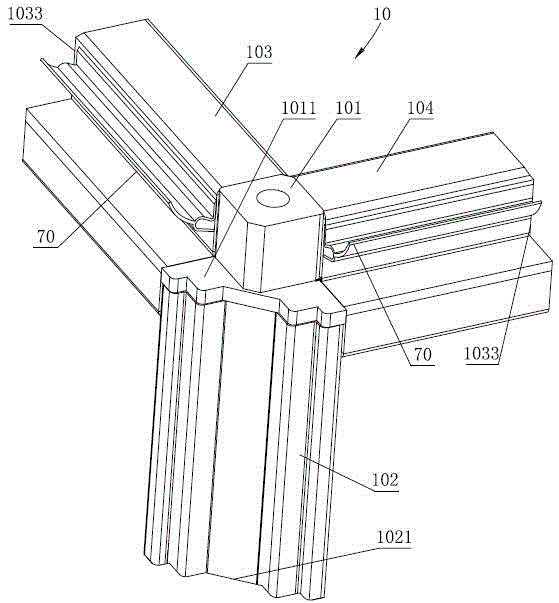

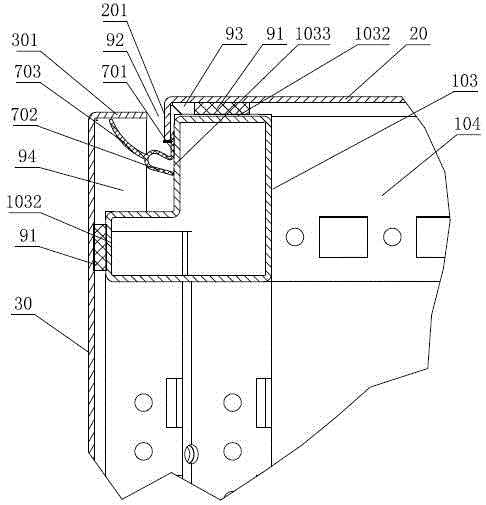

[0027] See figure 1 , figure 2 , the present invention comprises a frame 10, a cover plate 20 and a side plate 30 around the frame 10, a cabinet door is included in the side plate 30, and the frame 10 includes a top frame and a bottom frame, and a corner is passed between the top frame and the bottom frame. The connecting piece 101 is connected with the column profile 102 to form the frame 10; both the top frame and the bottom frame are formed by connecting two beam profiles 103 and two longitudinal beam profiles 104 to each other.

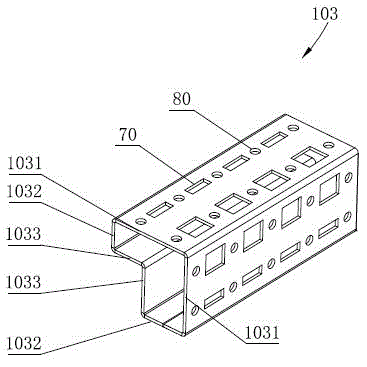

[0028] See figure 1 , image 3 , the beam profile 103 has two vertically connected installation sides 1031, the installation side 1031 faces the inside of the frame 10, the installation side 1031 extends towards the outside of the frame 10 and is connected with the sealing section 1032, the sealing section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com