Composite crusting dust suppressant and preparation method thereof

A dust suppressant and composite technology are applied in the field of composite crust dust suppressants and their preparation, which can solve the problems of inability to store for a long time, poor stability, etc., and achieve the effects of simple operation, stable properties and reduction of reaction sites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

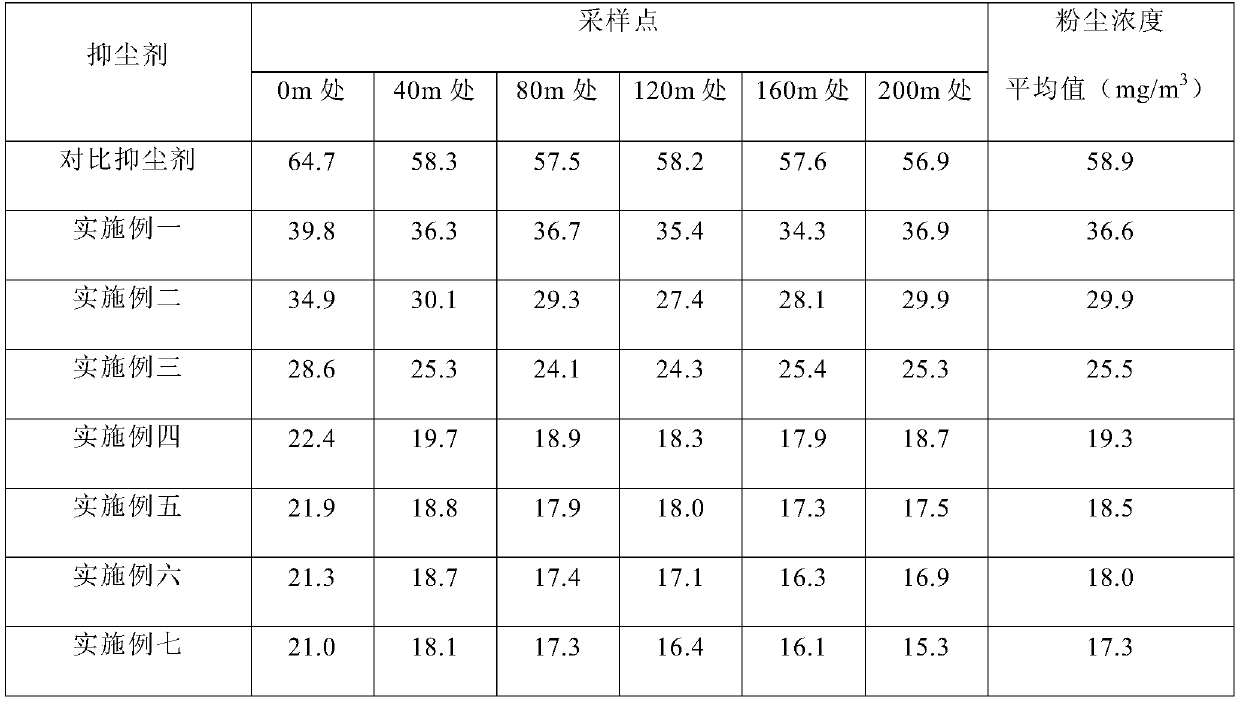

Examples

Embodiment 1

[0073] Example 1: Pour 0.25kg of the above-mentioned composite crust dust suppressant raw slurry into the equipment container, and then add 0.5m 3 tap water, utilize the impact force of water to dilute and dissolve, and obtain embodiment one composite crust dust suppressant.

Embodiment 2

[0074] Example 2: Pour 0.5kg of the above-mentioned compound crust dust suppressant raw slurry into the equipment container, and then add 0.5m 3 tap water, utilize the impact force of water to dilute and dissolve, and obtain the compound crust dust suppressant of embodiment two.

Embodiment 3

[0075] Example 3: Pour 1 kg of the above-mentioned composite crust dust suppressant slurry into the equipment container, and then add 0.5m 3 tap water, and utilize the impact force of water to dilute and dissolve to obtain the composite crust dust suppressant of Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com