Higher-strength, cold-formable steel and steel sheet product consisting of such a steel

A high-strength, coldable technology, applied in the direction of manufacturing tools, furnace types, layered products, etc., can solve the problems of increased alloy cost and no effect on strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

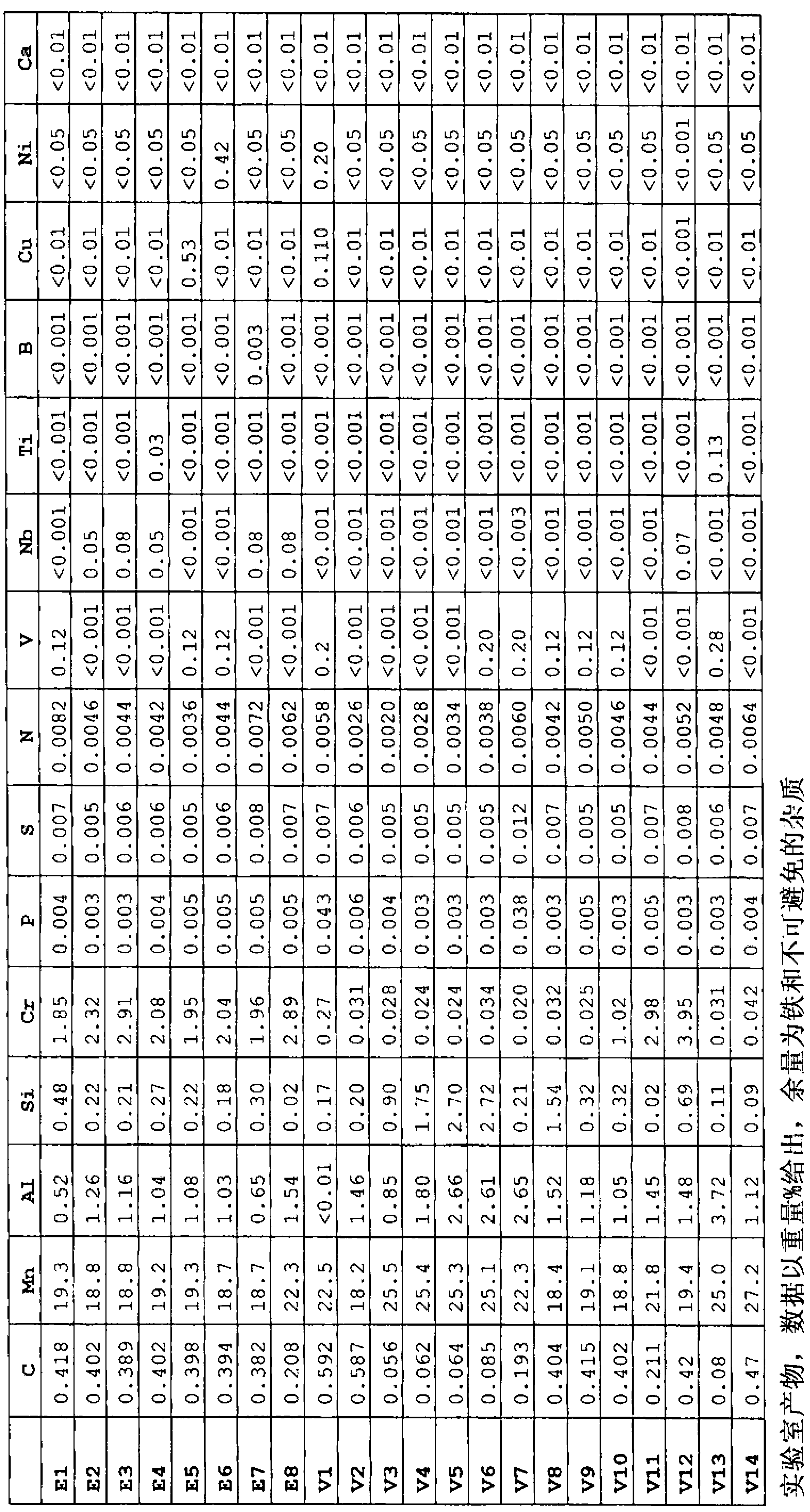

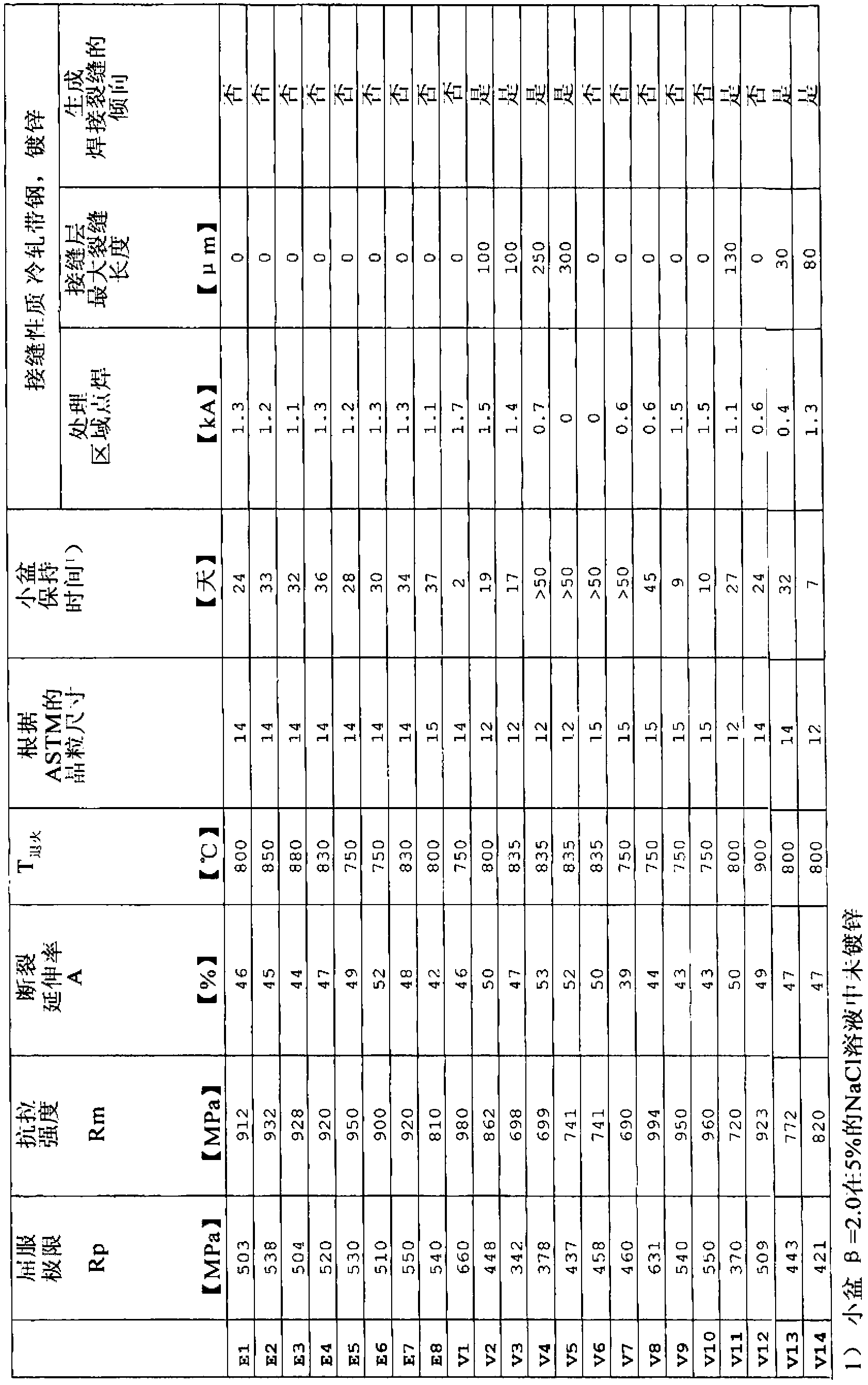

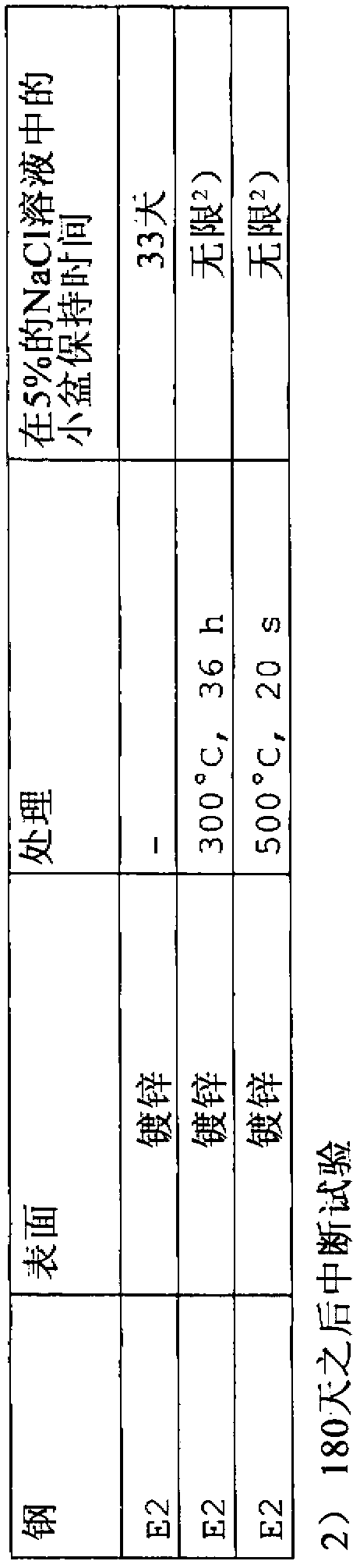

[0073] In Table 1, 8 alloys E1-E8 of the steel according to the invention and 14 comparative steel plates V1-V14 are given.

[0074] The cast steel ingots made of the steel E1-E8 according to the present invention and the comparative steel plates V1-V14 were heated at a preheating temperature of about 1250°C and then hot-rolled at a hot rolling temperature of about 950°C to a thickness of about 3 mm. Rolled steel sheet.

[0075] The resulting hot-rolled steel sheet is wound into coils at a winch temperature of about 20°C (room temperature).

[0076] After coiling, the hot-rolled steel sheet is cold-rolled to a cold-rolled strip with a thickness of 1 mm with a cold rolling degree of about 66%.

[0077] The cold-rolled strip obtained in this way is subjected to final annealing at the end of the continuous processing steps. During the annealing process, the steel plate is at a temperature of T annealing Medium heating for about 140 seconds, the temperature is below 890°C. The mechanica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bow to extremes | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com