Grain drying and conveying device with bent pipe

A conveying device and grain technology, applied in the direction of drying and preserving seeds, dyeing organic silicon compound treatment, dyeing low-molecular organic compound treatment, etc., to achieve the effect of saving time and effort in operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

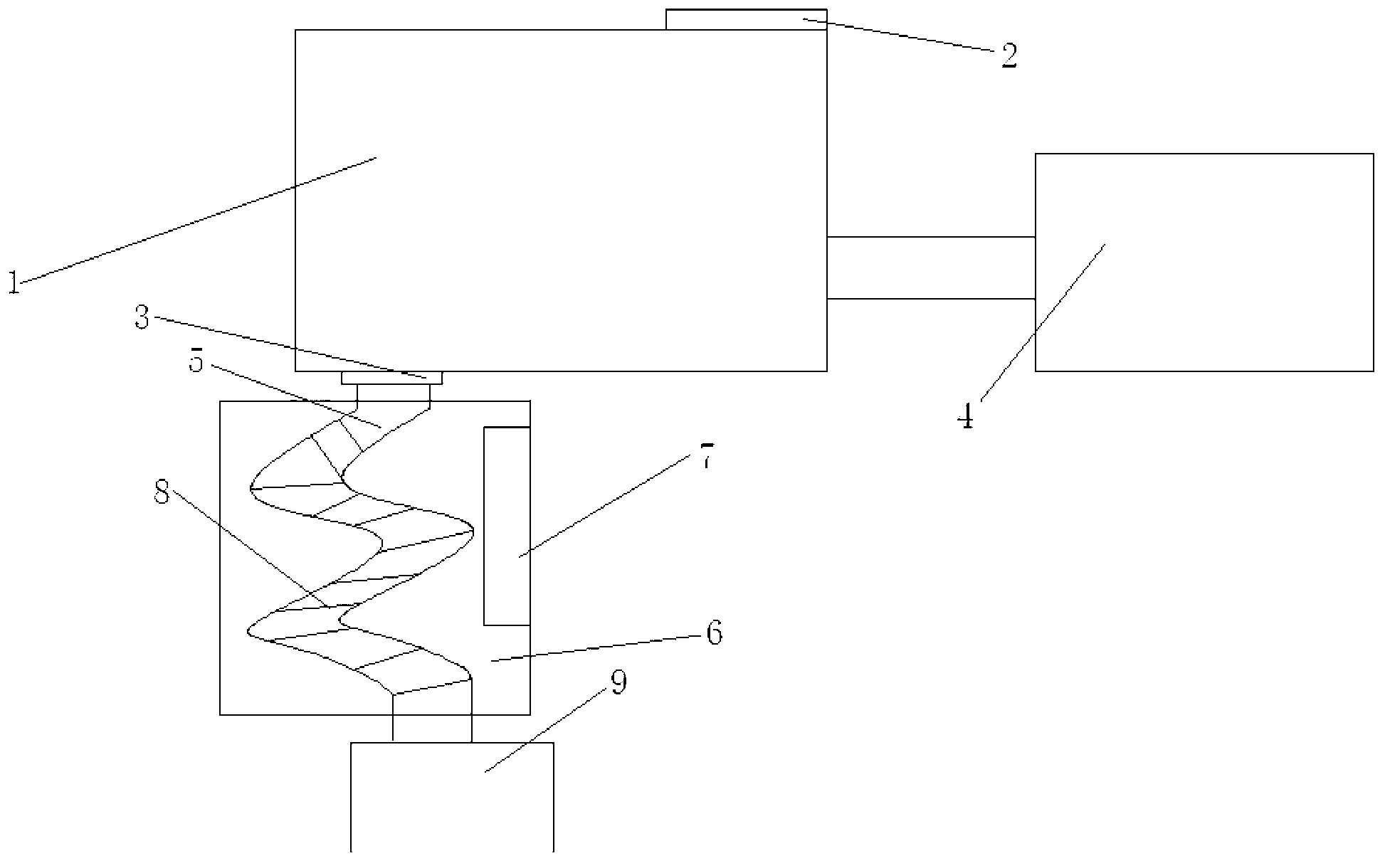

[0032] see figure 1 , a kind of grain drying and conveying device with an elbow, including an oven 1, an inlet 2 is provided on the oven 1, an outlet 3 is provided on the bottom surface of the oven 1, and the oven 1 communicates with a hot air blower 4 , the bottom of the oven 1 is provided with a snake-shaped feeding pipe 5 made of high-temperature-resistant nylon material, and the outlet 3 on the bottom surface of the oven is facing the mouth of the snake-shaped feeding pipe 5. A casing 6 is arranged outside the material pipe 5, a heater 7 is installed in the casing 6, and a layer of thermal insulation cotton 8 is coated on the pipe wall of the serpentine feeding pipe 5.

[0033] The bottom of the casing 6 is provided with a collection box 9 , and the serpentine feeding pipe 5 protrudes from the bottom surface of the casing 6 and faces the collection box 9 .

[0034] The outside of the oven is coated with a special metal anti-rust paint, which is made of the following raw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com