Rapid preparation method of soy sauce secondary protein precipitation

A secondary precipitation and soy sauce technology, which is applied in food preparation, application, food science, etc., can solve the problems of protein differences, small content, long time, etc., and achieve the comprehensive effect of scientific methods, mild conditions, and secondary protein precipitation of soy sauce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

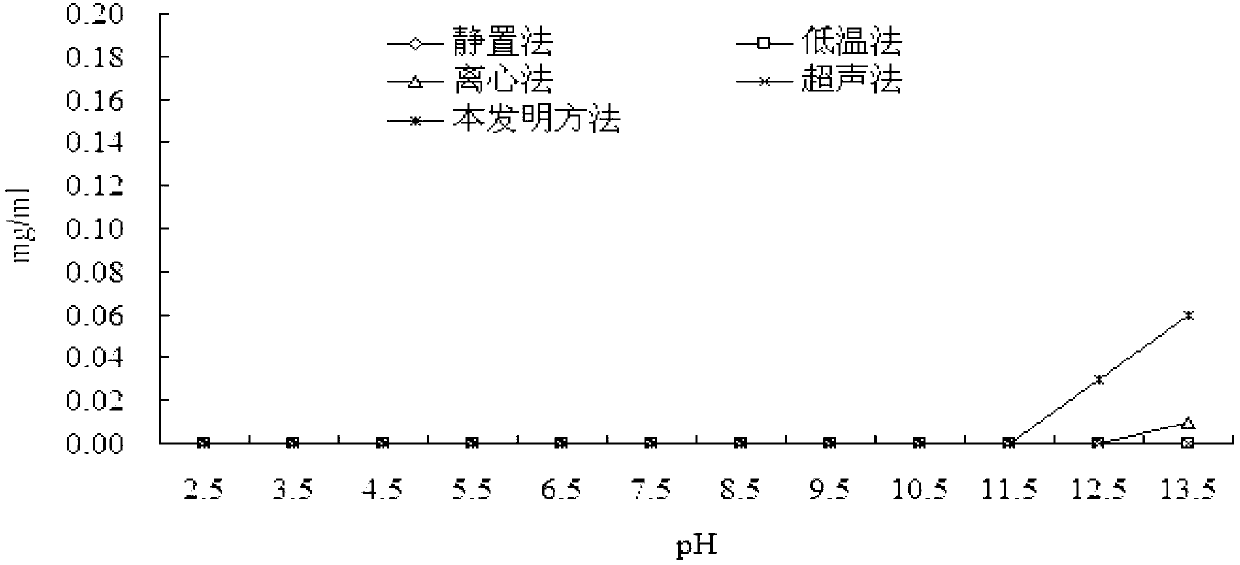

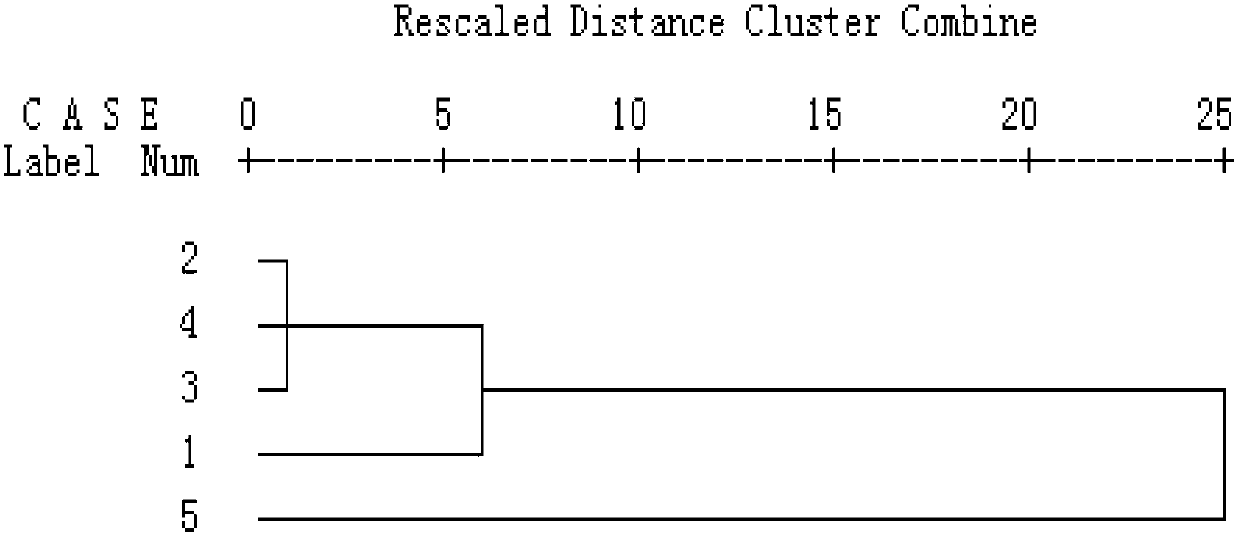

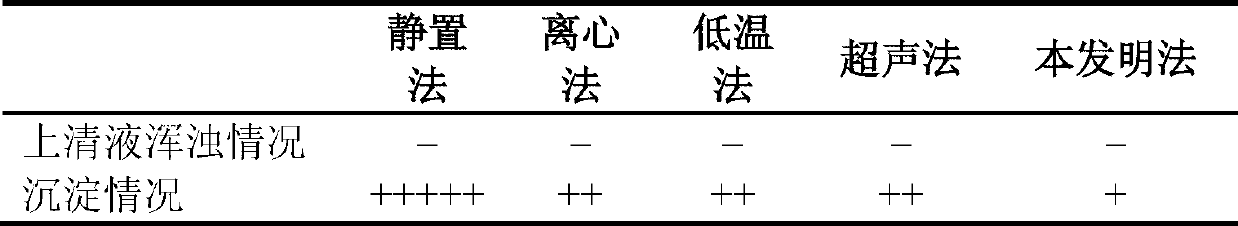

[0028] The soy sauce was pre-cooled to -7°C in the refrigerator, and 200mL of soy sauce was ultrasonicated for 8 minutes under the conditions of power 950W and frequency 20KHz, and the sample was pre-cooled to -7°C again, and then the sample was centrifuged at a relative centrifugal force (RCF) of 3600g for 30 minutes and collected precipitation. Wash the precipitate with 4 times the volume of deionized water and put it into a dialysis bag with a molecular weight cut-off of 3500Da for desalting and dialysis to obtain a high-purity soy sauce secondary precipitate protein suspension. Vacuum freeze-dry the suspension to obtain the secondary precipitated protein of high-purity soy sauce. Compared with the control, the soy sauce secondary precipitation protein prepared by the present invention is insoluble in water (pH3-6) within the normal pH range of soy sauce ( figure 1 ), and the soy sauce treated by the method of the present invention no longer precipitates (Table 1), indicat...

Embodiment 2

[0033] Soy sauce was pre-cooled to 5°C in the refrigerator, 200mL soy sauce was ultrasonicated for 16min under the conditions of power 200W and frequency 10KHz, the sample was pre-cooled to -7°C again, and then the sample was centrifuged at a relative centrifugal force (RCF) of 17000g for 10min and the precipitate was collected . Wash the precipitate with 4 times the volume of deionized water and put it into a dialysis bag with a molecular weight cut-off of 10,000 Da for desalting and dialysis to obtain a high-purity soy sauce secondary precipitate protein suspension. Vacuum freeze-dry the suspension to obtain the secondary precipitated protein of high-purity soy sauce. Compared with the control, the soy sauce secondary precipitation protein prepared by the present invention is insoluble in water within the normal pH range of soy sauce (pH3-6), and the soy sauce treated by the method of the present invention no longer appears precipitated (Table 1), indicating that the soy sau...

Embodiment 3

[0035] The soy sauce was pre-cooled to -10°C in the refrigerator, and 200mL of soy sauce was ultrasonicated for 6 minutes under the conditions of power 500W and frequency 15KHz, and the sample was pre-cooled to -10°C again, and then the sample was centrifuged at a relative centrifugal force (RCF) of 5000g for 25 minutes and collected precipitation. Wash the precipitate with 4 times the volume of deionized water and put it into a dialysis bag with a molecular weight cut-off of 5000Da for desalting and dialysis to obtain a high-purity soy sauce secondary precipitate protein suspension. Vacuum freeze-dry the suspension to obtain the secondary precipitated protein of high-purity soy sauce. Compared with the control, the soy sauce secondary precipitation protein prepared by the present invention is insoluble in water within the normal pH range of soy sauce (pH3-6), and the soy sauce treated by the method of the present invention no longer appears precipitated (Table 1), indicating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com