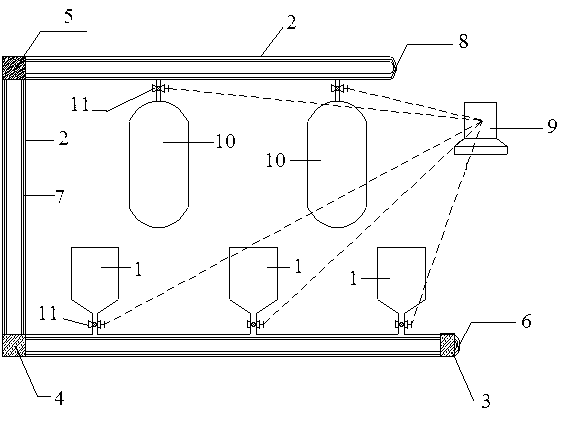

Fully enclosed solid material feeding system and feeding method

A solid material, fully enclosed technology, applied in chemical instruments and methods, feeding devices, chemical/physical processes, etc., can solve problems such as unsuitable exposure, toxic chemical raw materials, and unsuitable solid material transportation methods for chemical production, etc., to achieve The effect of saving manpower and material resources and reliable operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0033] Example 1: Add 3000Kg melamine alone

[0034] 1. Before feeding, first check whether the equipment is in good condition and clean, and check whether the amount of melamine in the feeding tank meets the requirements through the weighing module. If everything is ok go to the next step.

[0035] 2. Set the DCS system command, according to the command, 100% open the bottom valve below the feeding trough, and open the vibrating hammer at the same time, the frequency is 5S / time.

[0036] 3. The material starts to enter the first pipe chain 6. According to the DCS system command, the first transmission device 3 is turned on. According to the material characteristics, the power of the transmission device is automatically adjusted to 20% of the rated power.

[0037] 4. The material begins to enter the second pipe chain 7. According to the DCS system command, the second transmission device 4 is turned on. According to the change of the current in the first pipe chain 6, the powe...

example 2

[0048] Example two: 3300Kg melamine and 4500Kg solid formaldehyde are mixed together

[0049] 1. Before feeding, first check whether the equipment is in good condition and clean, and check whether the quantity of melamine and solid formaldehyde in the feeding tank meets the requirements through the weighing module. If everything is ok go to the next step.

[0050] 2. Set the DCS system command. According to the command, 100% open the bottom valve below the feeding tank, and at the same time open the vibrating hammer with a frequency of 5S / time, and open 65% of the bottom valve of the solid formaldehyde feeding tank.

[0051] 3. The material starts to enter the first pipe chain 6. According to the DCS system command, the first transmission device 3 is turned on. According to the material characteristics, the power of the transmission device is automatically adjusted to 28% of the rated power.

[0052] 4. The material starts to enter the second pipe chain 7. According to the DC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com