Mill roll material chute

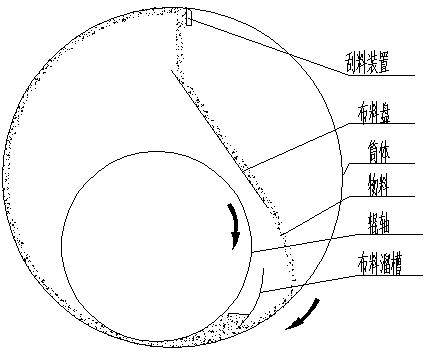

A technology of distributing chute and horizontal roller mill, which is applied in the field of horizontal roller mill, can solve the problems of low material grinding efficiency, insufficient material grinding, unstable material bed, etc., and achieve the goal of improving grinding efficiency and machine-hour output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the utility model is described in further detail:

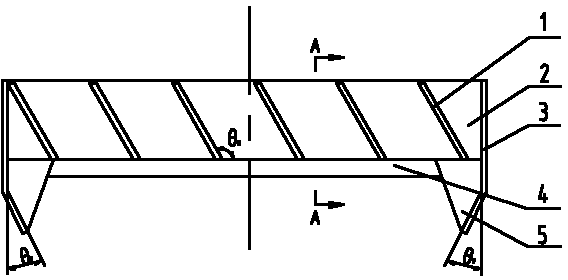

[0015] The invention provides a distribution chute, which includes a material guide plate 1, an arc plate 2, a lateral material retaining plate 3, an axial material retaining plate 4 and a rib plate 5, and the back of the arc plate 2 of the distribution chute is welded with multiple pieces of "1" Material guide plate 1, angle between material guide plate 1 and end face

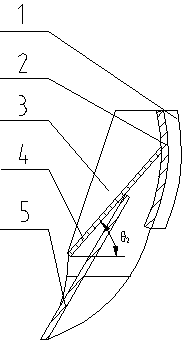

[0016] θ 3 =150°; the upper end surface of the axial baffle plate 4 is fixed on the inner arc surface of the arc plate 2, and its end surface is fixed by two symmetrically arranged lateral baffle plates 3, and the inner surface of the lower half of the lateral baffle plate 3 passes through The ribs 5 are connected to the axial baffle 4 . The angle θ formed by the axial baffle plate 4 and the horizontal plane of the cylinder 2 =60°; the angle θ between the lower part of the side b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com