Automatic adjustment method and system of speed synchronism of casting machine and rolling machine

A technology of automatic adjustment and automatic control system, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of multiple hardware equipment, difficulty, inability to fully reflect the real situation of the slab, and achieve automatic The effect of control and regulation to improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

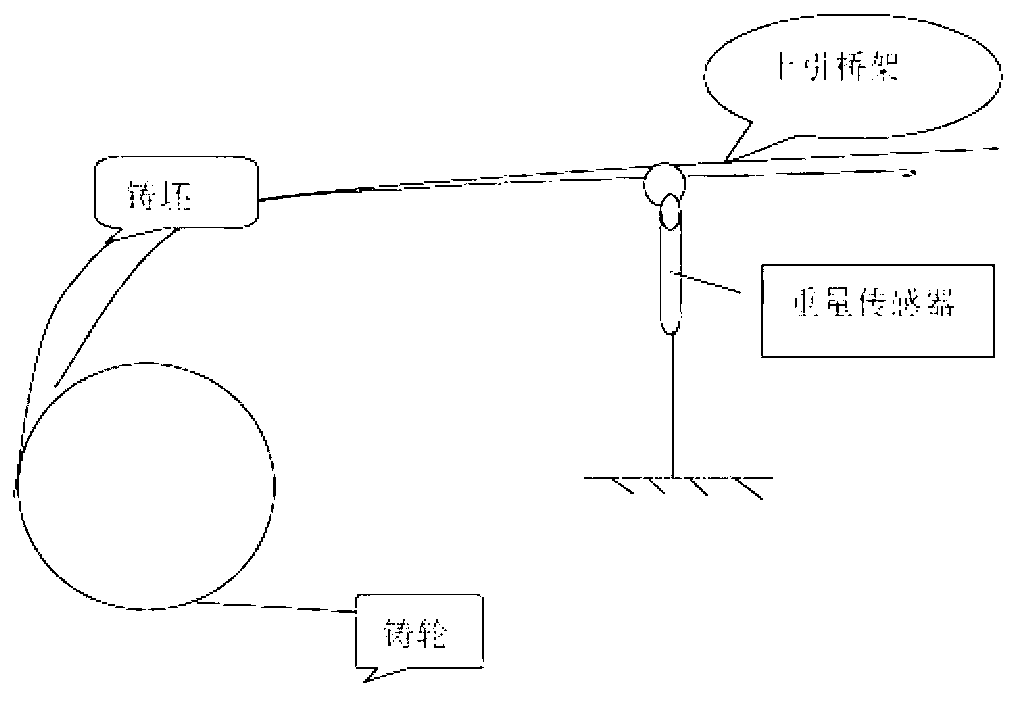

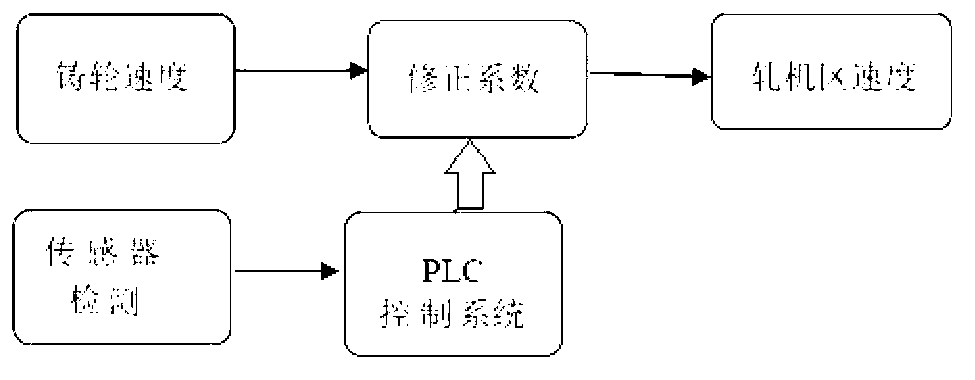

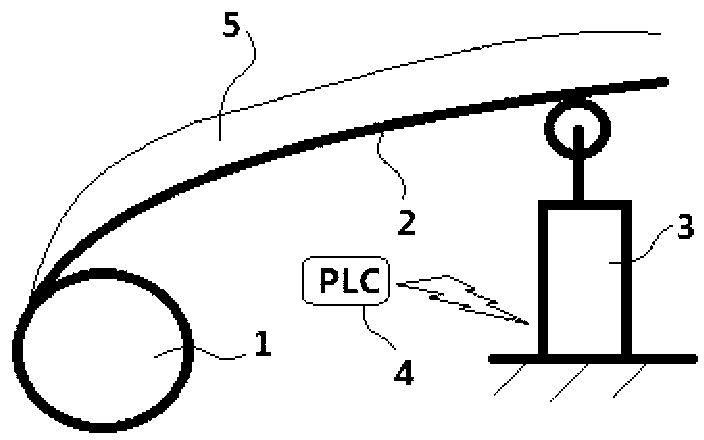

[0022] Such as figure 1 , figure 2 , image 3 As shown, a weight sensor 3 is installed on the upper approach bridge frame 2 between the billet 5 and the rolling mill, and the weight of the sensor 3 enters the PLC system 4 for automatic control. Then, write a section about the speed adjustment of the rolling mill in the PLC control program. The PID closed-loop control program generates a coefficient that automatically corrects the speed of the rolling mill, and a weight value when the billet is synchronized with the normal speed of the rolling mill is input into the control program.

[0023] When the actual weight display is greater than the set value, it means that the metal second flow rate of the rolling mill is greater than that of the casting machine 1. At this time, the program can provide a correction system for the rolling mill speed through calculation. Synchronous; when the actual weight display is less than the set value, it means that the second metal flow rate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com