Grain drying control system

A technology for drying control and grain, which is applied in drying, grain drying, and drying solid materials, etc. It can solve the problems of inability to measure grain moisture quickly and accurately, poor stability and real-time performance, and high energy consumption of the drying system. Achieve the effect of fast and efficient signal processing, timely control of drying, and automatic control and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

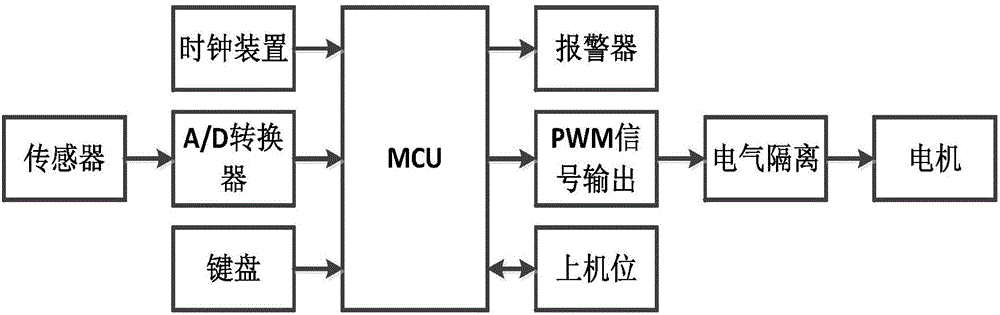

[0015] Such as figure 1 As shown, a grain drying control system includes an acquisition system, a processing control system, and a drive display system. The acquisition system includes sensors and A / D converters connected in sequence. The sensors include humidity sensors, temperature sensors, and position sensors. The grain in the drying system is tested for humidity, temperature and position. The processing control system includes a clock device and a single-chip microcomputer. The A / D converter is connected to the single-chip microcomputer, and the clock device is connected to the single-chip microcomputer to provide a clock signal to the single-chip microcomputer. The clock device uses a temperature-compensated crystal oscillator with a differential level synchronous pulse output, so that the clock deviation is not greater than one millisecond. Further, the processing control system also includes a keyboard, which is connected to a single-chip microcomputer to facilitate s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com