Inlet steam control system and supplementary steam control method of dual-cylinder dual-pressure waste heat generator set

A technology for generating sets and control systems, applied to engine components, machines/engines, combined engines, etc., can solve problems such as water erosion of steam turbine final stage blades, high control requirements, and defects in low-pressure steam power generation, so as to improve power generation efficiency and use life, reducing the frequency of adjustment, and improving the effect of operating stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

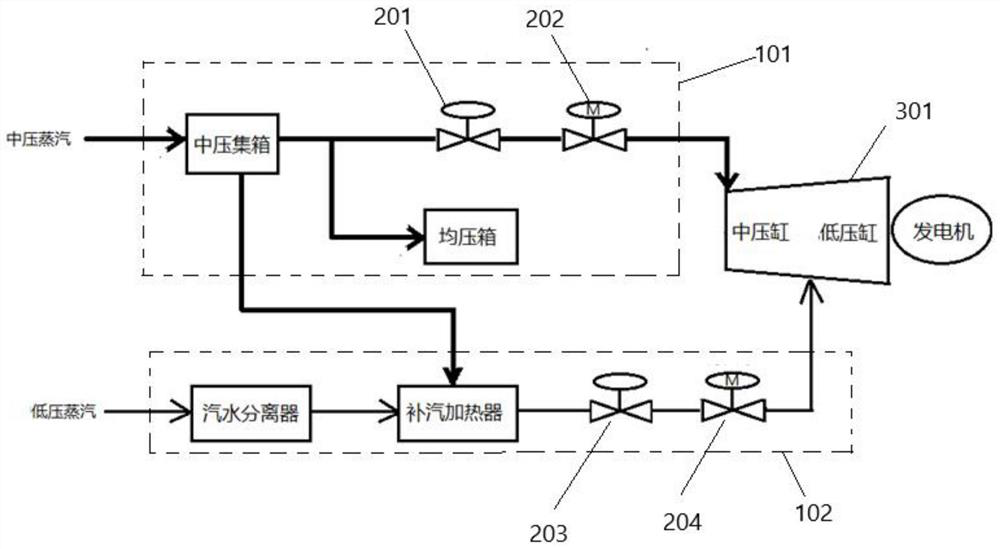

[0031] The steam inlet control system of the dual-cylinder dual-pressure waste heat generator set of the present invention includes a main steam adjustment unit, an auxiliary steam adjustment unit and a DEH, and the main steam adjustment unit includes a medium pressure header, a first quick cut valve and a first adjustment valve , the air outlet of the medium-pressure header is connected with the first quick-cut valve, and the first regulating valve is respectively connected with the first quick-cut valve and the medium-pressure cylinder of the generator set; the supplementary steam regulating unit includes a steam-water separator, a heating The air inlet of the heater is connected with the air outlet of the steam-water separator and the air outlet of the medium pressure header respectively, and the air outlet of the heater is connected with the second quick cut valve, The second regulating valve is respectively connected with the low pressure cylinder of the generator set and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com