Tool of low-pressure hub and heat treatment method for forming low-pressure hub

A low-pressure wheel and tooling technology, used in heat treatment furnaces, heat treatment equipment, workpiece clamping devices, etc., can solve the problems of lack of tooling, difficulty in determining the phase angle of the wheel disc, etc., to reduce labor intensity, clear steps, and high success rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

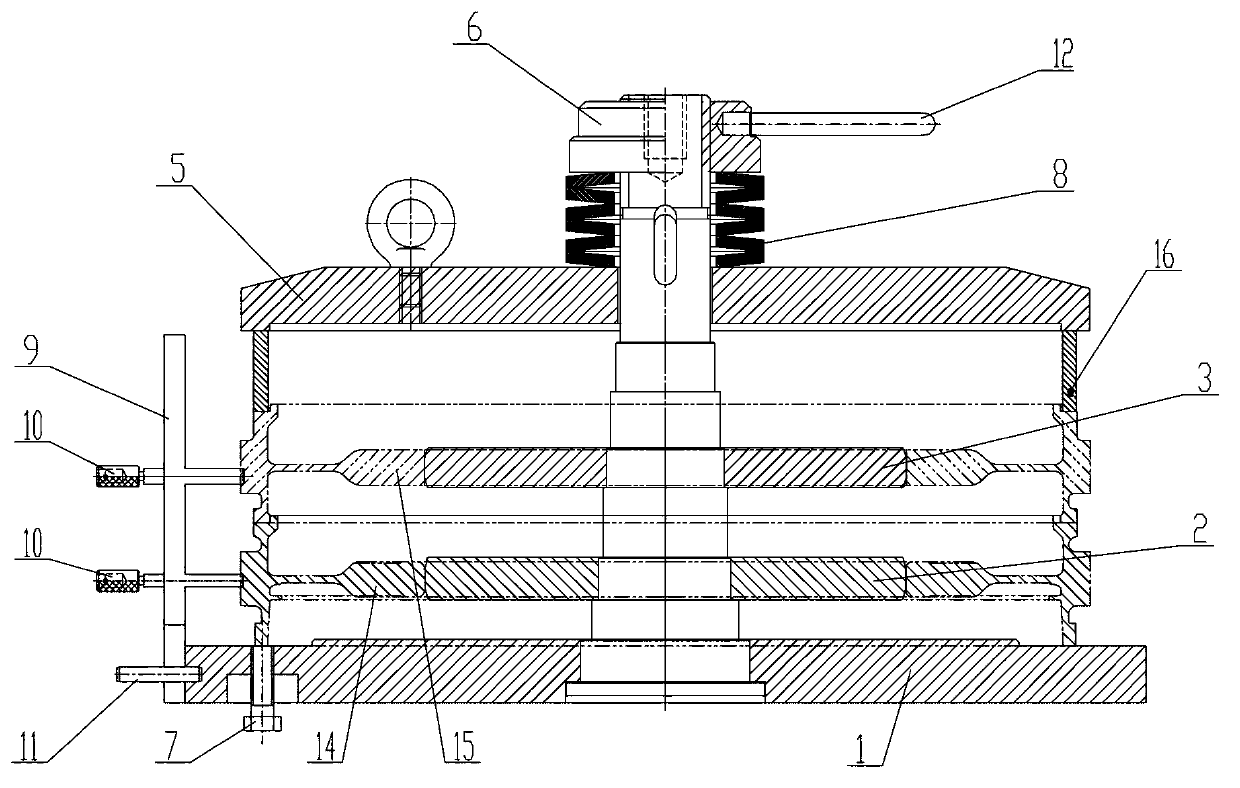

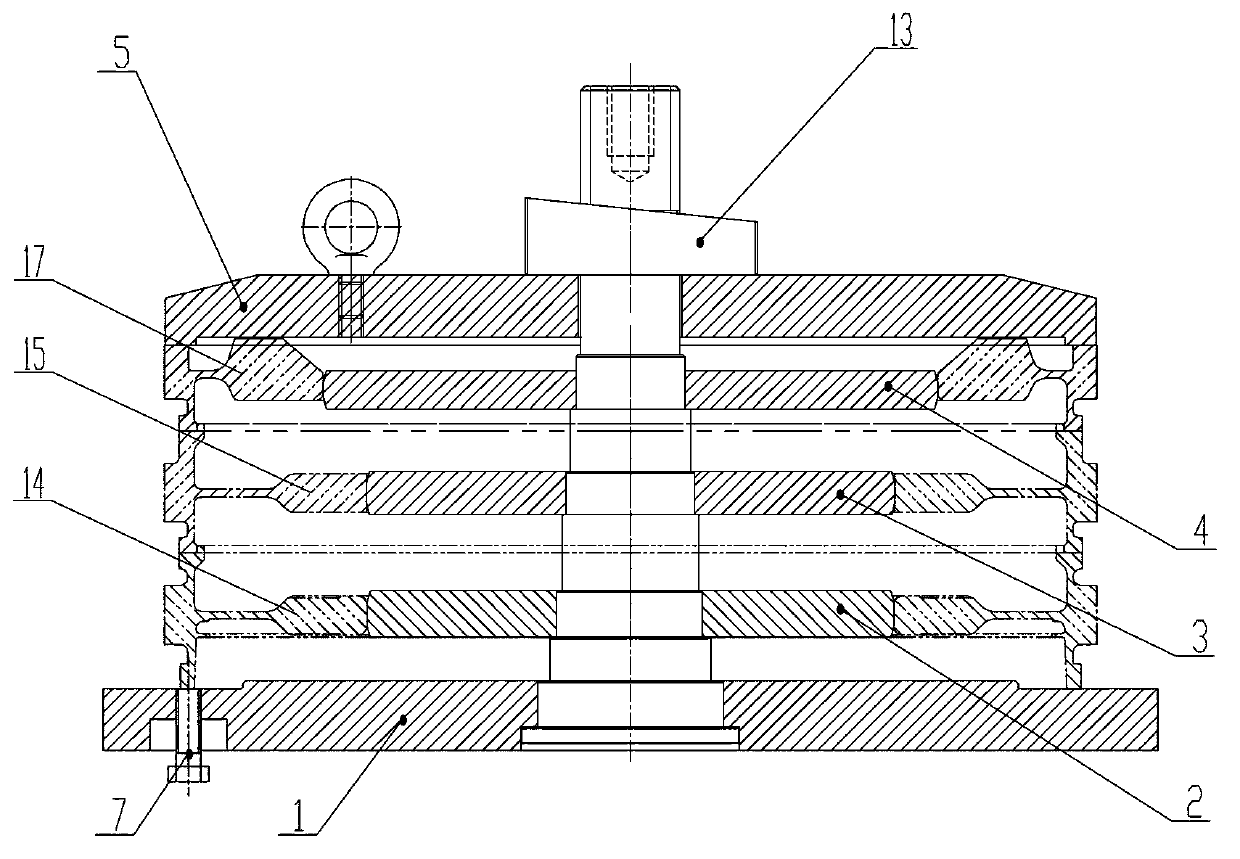

[0019] Specific implementation mode one: combine figure 1 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 Describe this embodiment, the tooling described in this embodiment is the assembly tooling of a primary and secondary roulette, and the assembly tooling of the primary and secondary roulette includes a mold 1, a first mandrel body 2, and a second mandrel body 3 , a gland 5, a nut 6, a bolt 7, an elastic device 8, a support plate 9, a secondary press-fit workpiece 16 and two positioning pins 10, the mold 1 includes a chassis 1-1 and a mandrel 1-2 , the chassis 1-1 is arranged horizontally, the mandrel 1-2 is arranged vertically, the mandrel 1-2 is a stepped shaft body, and the large diameter end of the chassis 1-1 and the mandrel 1-2 is fixedly connected Made as a whole, the mandrel 1-2 is sequentially fitted with the first mandrel body 2, the second mandrel body 3 and the gland 5 from the large-diameter end to the small-diamete...

specific Embodiment approach 2

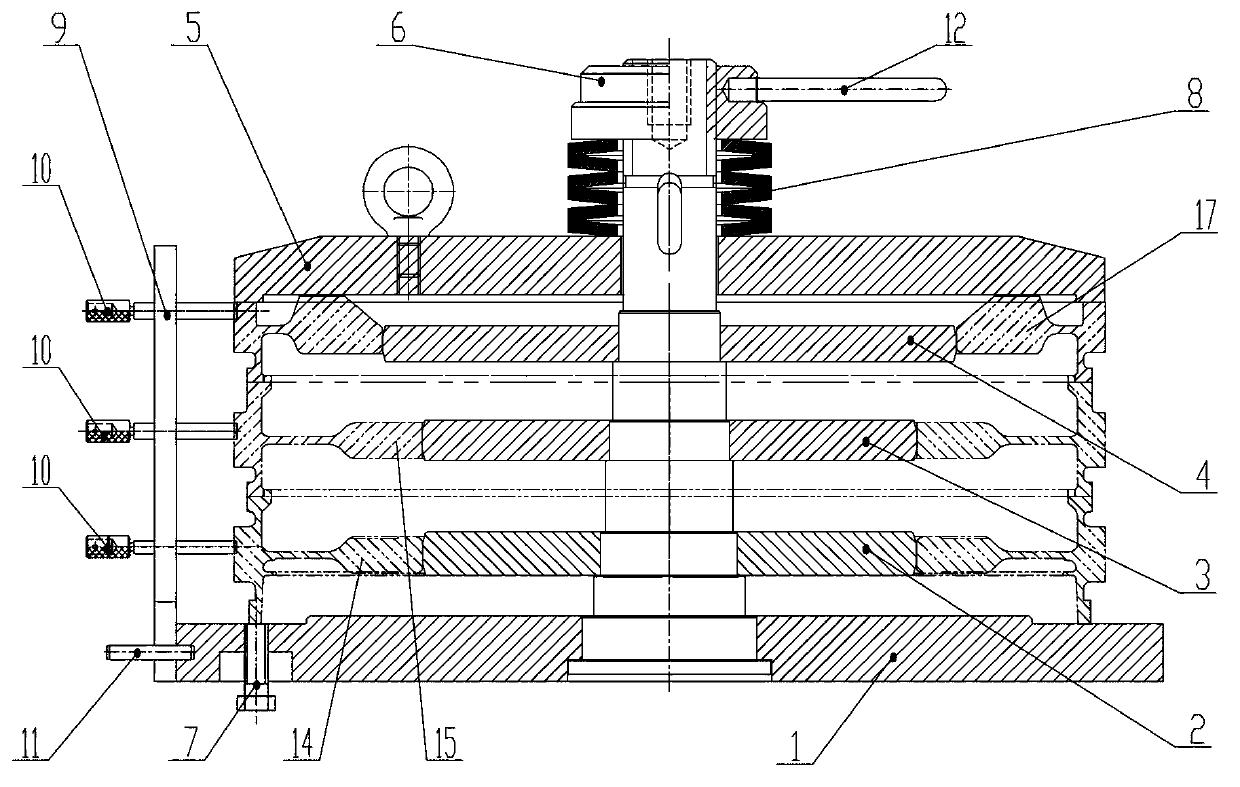

[0020] Specific implementation mode two: combination figure 2 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10Describe this embodiment. The tooling described in this embodiment is the assembly tooling of the second and third stage roulettes, and the assembly tooling of the second and third stage roulettes includes a mold 1, a first mandrel body 2, and a second mandrel body 3 , the third mandrel body 4, the gland 5, the nut 6, the bolt 7, the elastic device 8, the support plate 9 and three positioning pins 10, the mold 1 includes a chassis 1-1 and a mandrel 1-2 , the chassis 1-1 is arranged horizontally, the mandrel 1-2 is a vertically arranged stepped shaft body, and the large diameter end of the mandrel 1-2 passes through the through hole on the chassis 1-1 and the chassis 1-1 is fixedly connected as a whole, and the mandrel 1-2 is sequentially fitted with the first mandrel body 2, the second mandrel body 3, the third mandrel body...

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 1 , figure 2 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 This embodiment will be described. In this embodiment, the elastic device 8 is a belleville spring. Belleville springs can achieve better utility model effects. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com