Clamp for lathing ventilation face of volute

A volute and face turning technology, applied in the directions of clamping, manufacturing tools, supports, etc., can solve the problems that affect the machining accuracy of the joint face turning, affect the machining quality of the workpiece, and the fixation cannot be guaranteed, so as to improve the machining quality of the workpiece and improve the turning Machining accuracy, the effect of avoiding offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

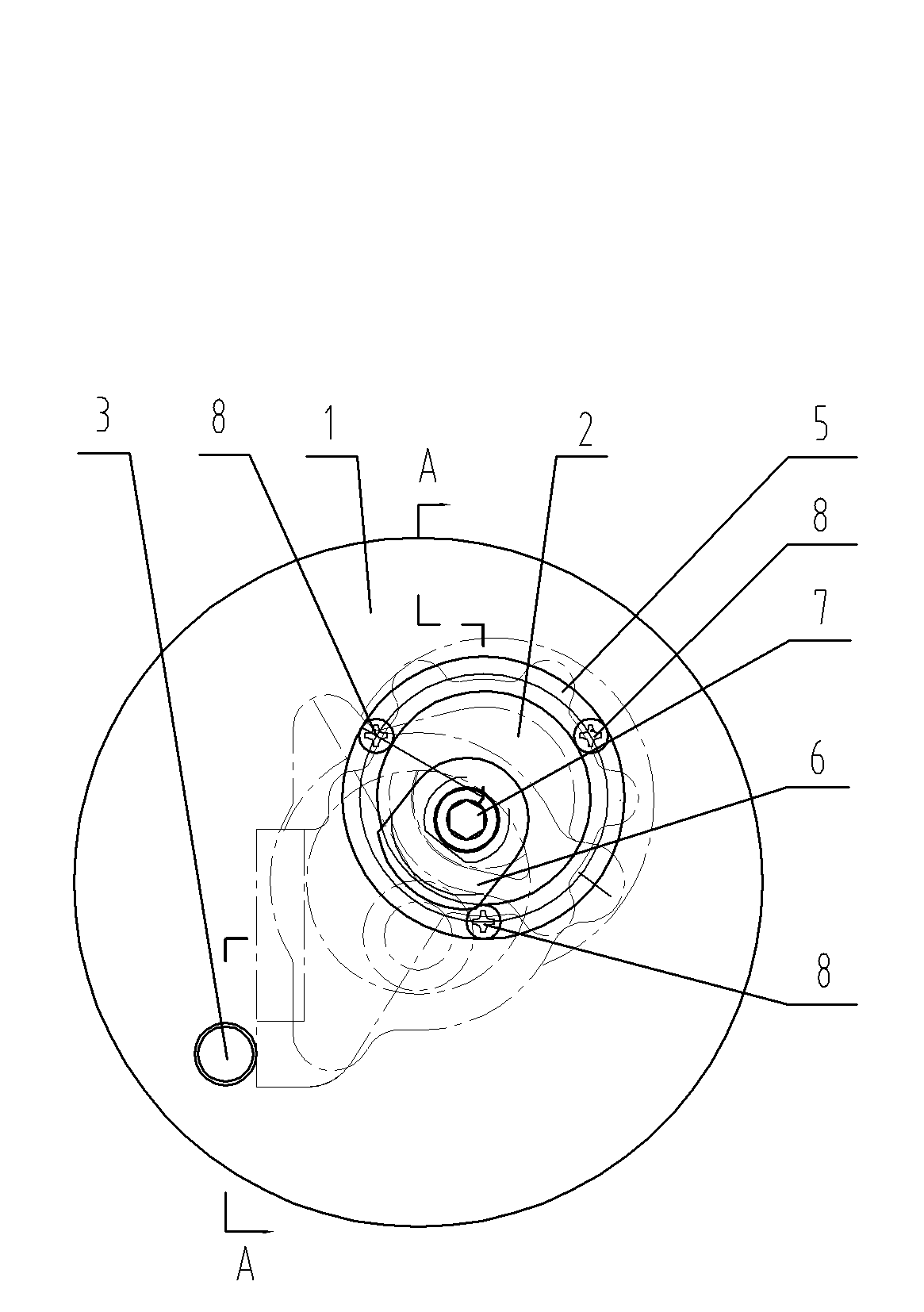

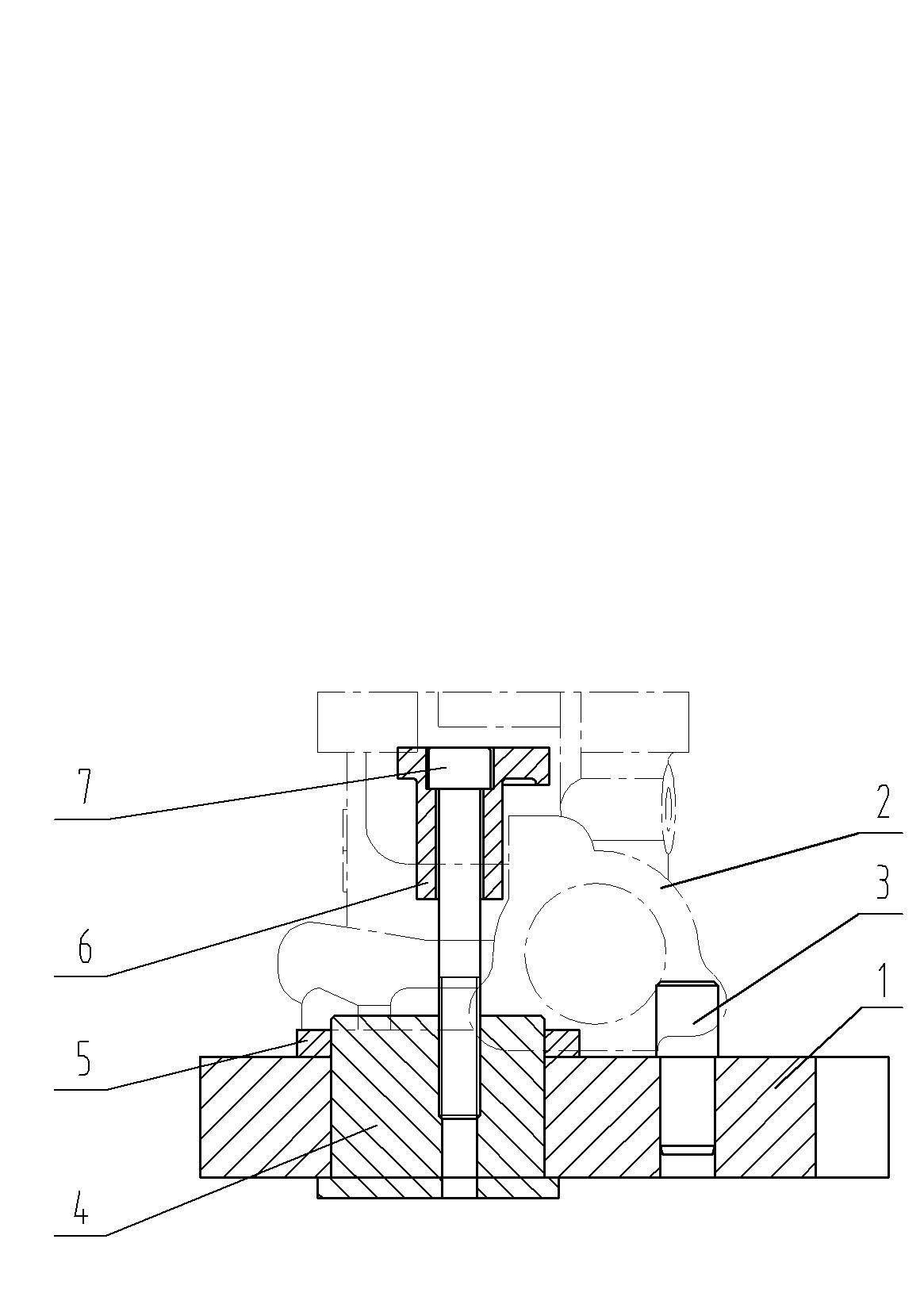

[0011] See figure 1 and figure 2 , the vehicle fixture for the air outlet surface of the volute, which includes a chassis 1, which includes a positioning boss 4, a support ring 5, a limit surface is provided at the bottom of the positioning boss 4, a perforation is opened on the position of the chassis 1 deviated from the center of the circle, and the positioning boss 4 is inserted The chassis 1 is perforated, the support ring 5 is set on the positioning boss 4, the volute 2 to be processed is positioned on the positioning boss 4 through its joint surface, and is attached to the support ring 5, and the volute 2 to be processed is connected through its joint surface The hole and the supporting ring 5 and the chassis 1 are fastened with bolts 8; it also includes a hook-shaped pressing plate 6 and a press-fitting bolt 7. The internal spigot of the shell is fastened to the positioning boss 4 through the sleeve part with the press-fit bolt 7; it also includes the positioning pin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com