Full-automatic matrix four-side self-adhesive glue coating device and self-adhesive glue coating method

A fully automatic, back-adhesive technology, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve problems such as reduced production efficiency, low yield, and increased labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

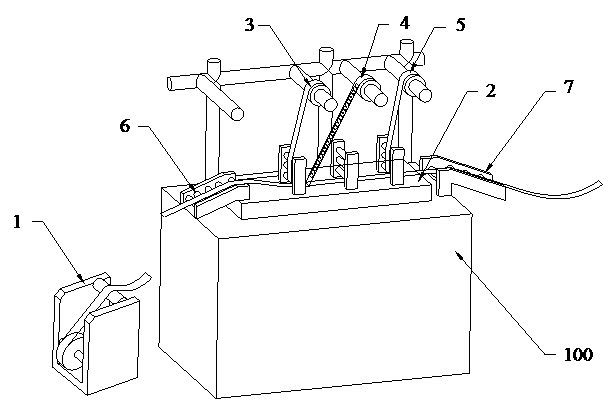

[0026] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to understand the essence of the present invention more clearly and intuitively.

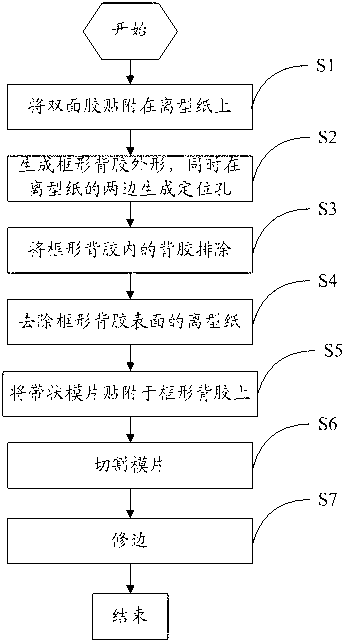

[0027] figure 1 It is a schematic flow chart of the method for fully automatic adhesive backing on the four sides of the die in the embodiment of the present invention.

[0028] refer to figure 1 As shown, the present embodiment provides a method for fully automatic adhesive backing on four sides of a die, comprising the following steps:

[0029] S1: Attach the double-sided tape to the release paper;

[0030] S2: Generate a frame-shaped adhesive profile, and generate positioning holes on both sides of the release paper;

[0031] S3: remove the adhesive in the frame-shaped adhesive;

[0032] S4: Remove the release paper on the surface of the frame-shaped adhesive;

[0033] S5: Attach the strip die to the frame-shaped adhesive; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com