A kind of handmade blue calico printing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Choose a table with a height of about 75cm (subject to the convenience of operation) and a suitable size. The area of the table is about 200cm*150cm (based on the convenience of printing). Rusty iron plate.

[0021] (2) The fabric is white cotton cloth with a door width of 90cm, and the length is determined according to needs. Spread the cotton cloth evenly on the stainless iron plate.

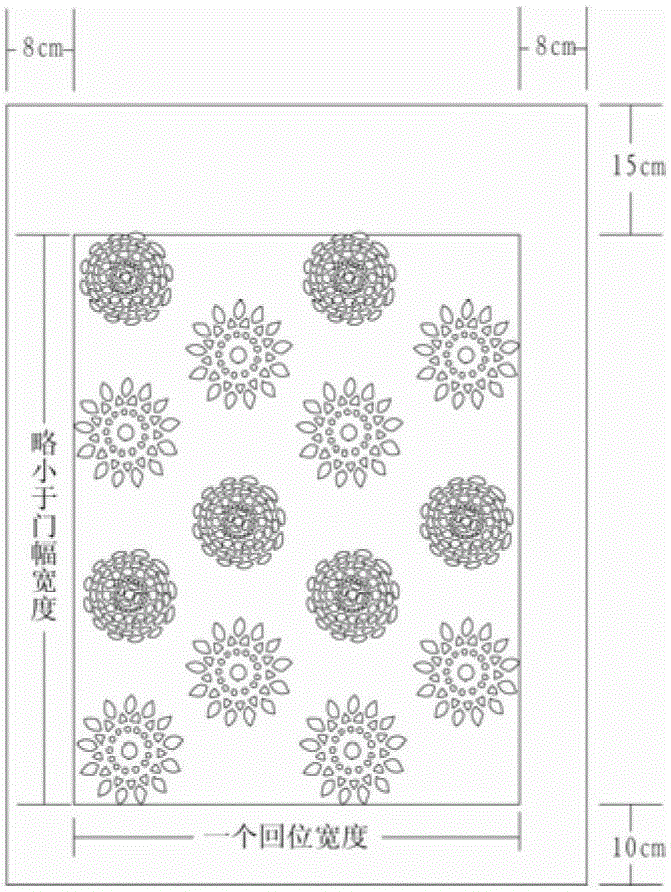

[0022] (3) Use magnetic PVC paper with a thickness of 0.5mm to carve a hollowed-out paper plate. The length of the magnetic PVC paper plate is wider than the width of the cotton cloth, but the hollowed out pattern part cannot exceed the width of the cotton cloth by 90cm, and the hollowed out magnetic PVC paper plate pattern part is reserved at least 5cm blank at the top, bottom, left, and right, and the unit return is 38*88cm.

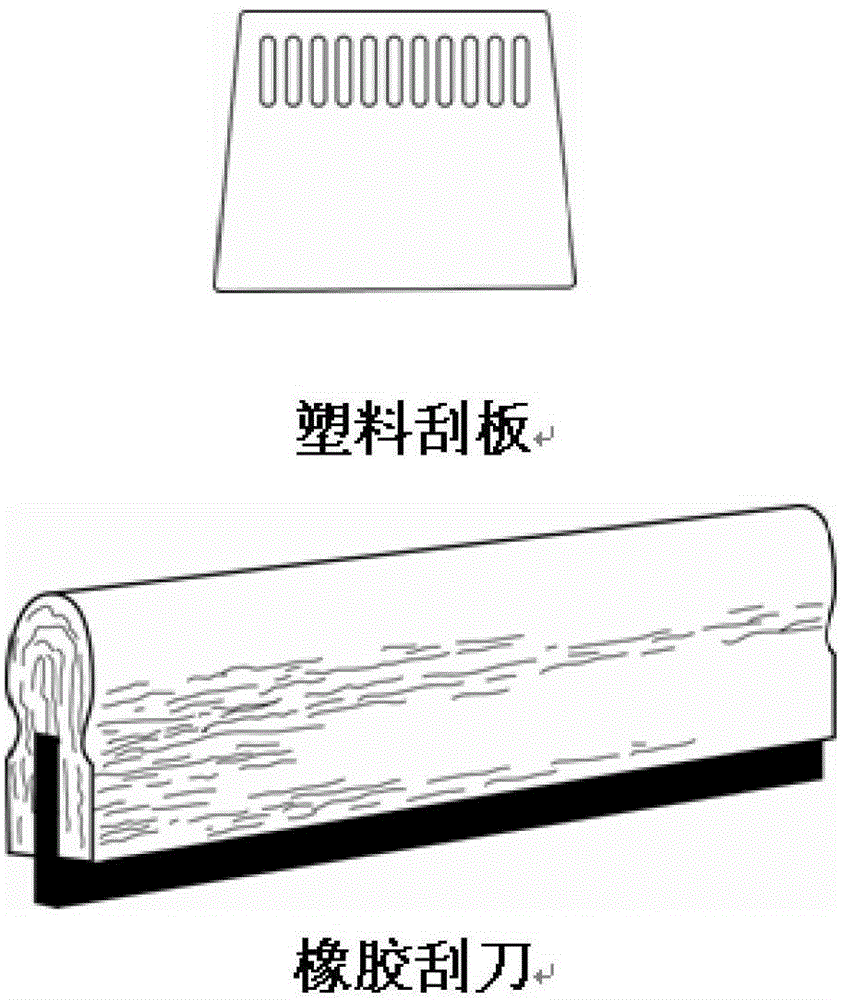

[0023] (4) Cover the magnetic PVC hollow-out paper plate on the cotton cloth to be scraped. Use a plastic scraper or a rubber scraper to evenly scrape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com