Structure of gravity launching buoyancy tank of roll-on roll-off ship

A ro-ro ship, gravity-type technology, applied in the field of ro-ro ship gravity-type launching buoyancy tank structure, can solve problems such as insufficient buoyancy of the tail, launching, thin outer plate shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

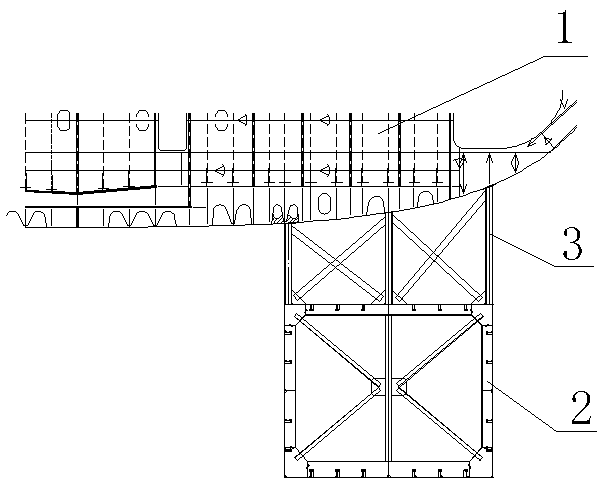

[0016] refer to figure 1 As shown in the structural schematic diagram of the present invention (the accompanying drawing is the right side figure, and the left side figure is symmetrical to it), a kind of ro-ro ship gravity type launching buoyancy tank structure disclosed by the present invention is under the stern hull of the ro-ro ship 1, left and right Respectively increase a pontoon 2 on both sides of the side.

[0017] The pontoon 2 is fixed below the outer plate of the ro-ro ship 1 through a bracket 3, and has a size of 15m*6m*5m. The buoyancy of the two pontoons 2 increases by 842 tons (8.42*106N) in total, while the steel weight of a single pontoon 2 is 18.2 tons, which greatly increases the buoyancy of the stern of the ro-ro ship 1, and effectively solves the local insufficient strength of the bottom of the ro-ro ship 1 and the tail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com