Material feeding mechanism

A material and material table technology, applied in the field of material supply mechanism, to achieve the effect of structural order receiving and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

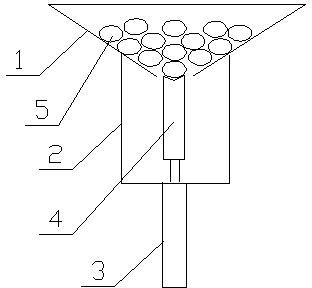

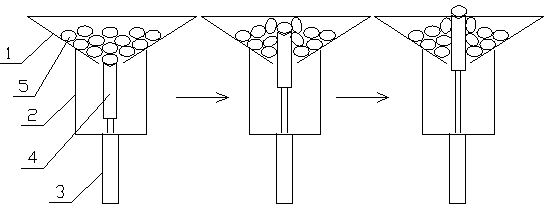

[0015] see figure 1 and figure 2 , A kind of material supply mechanism that the present invention relates to, is made up of material holding container 1, frame 2, air cylinder 3 and material platform 4.

[0016] The material holding container 1 is fixed on the top of the frame 2, and the shape of the material holding container 1 is large at the top and small at the bottom, so that the material can be gathered toward the lowest part of the container (such as a trumpet shape). There is a gap at the bottom; the cylinder 3 is fixed on the bottom of the frame 2, and the material table 4 is fixed on the end of the cylinder 3 push rod.

[0017] The material platform 4 can freely move up and down in the gap at the bottom of the material holding container 1, and the width of the material platform 4 can ensure that only one material is lifted at a time; The gap between the gaps is far from enough to allow the material to fall; the limit position of the downward movement of the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com