Plastic tray

A plastic pallet and wrinkle technology, applied in the field of plastic pallets, can solve the problems of short service life, low strength, high quality, etc., to save manpower and material resources, reduce costs, and improve bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

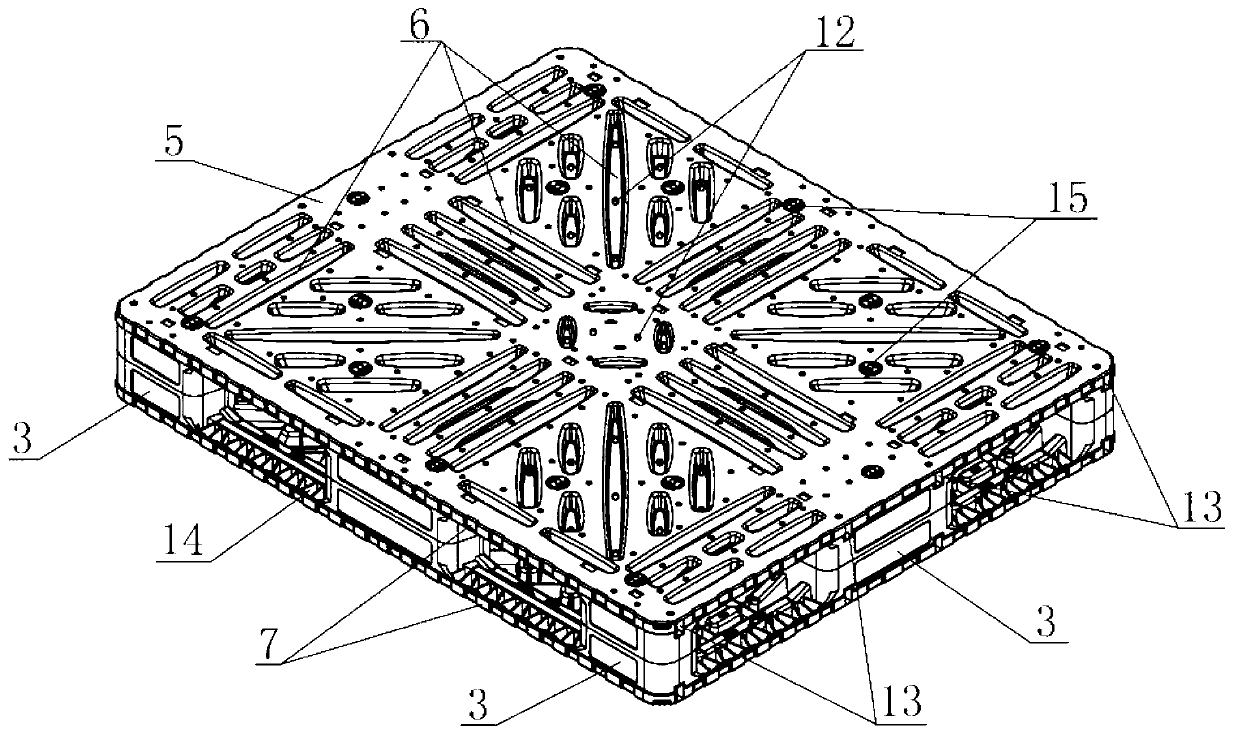

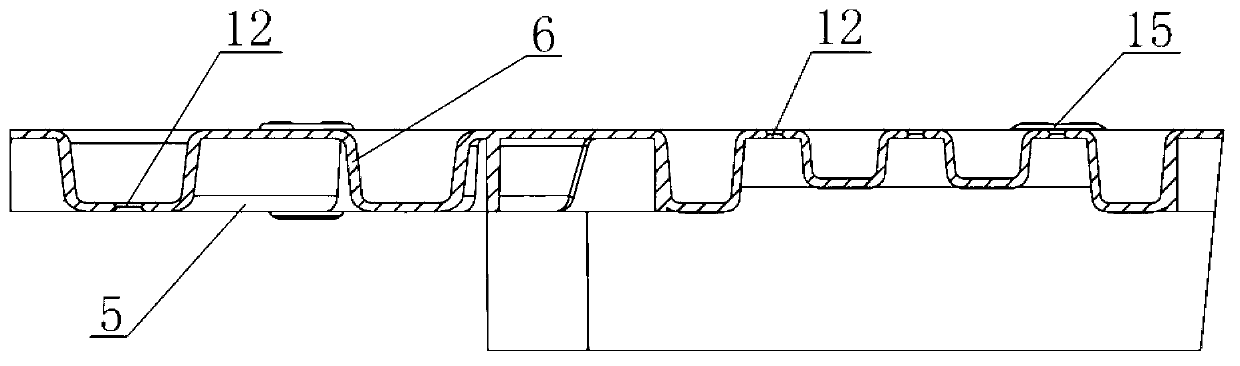

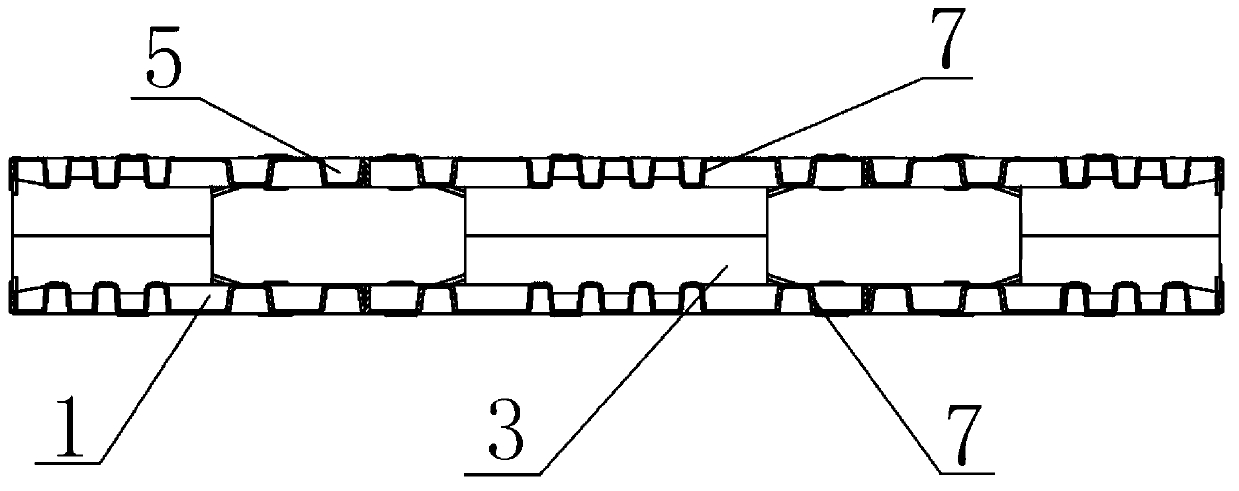

[0023] The plastic tray of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] like Figure 1 to Figure 6 As shown, the plastic tray of the present invention includes: a bottom plate 1, on which a plurality of support columns 3 and support seats 2 are arranged, wherein the support columns 3 are arranged on the edge of the bottom plate 1, between the support seats 2, the support columns 3 There are reinforcing ribs 4 inside. Cover plate 5, cover plate 5 is arranged on the base plate 1 through support column 3, is provided with leakage hole 12 and anti-slip mat groove 15 on cover plate 5, is provided with anti-slip mat in anti-slip mat groove 15. The anti-skid pad groove 15 includes a symmetrically arranged limiting plate 8 and a locking groove 9 arranged at the end of the limiting plate 8 . The anti-skid pad includes a pad body 10 and a buckle 11 disposed at the end of the pad body 10 , the position and size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com